4AC servo systems

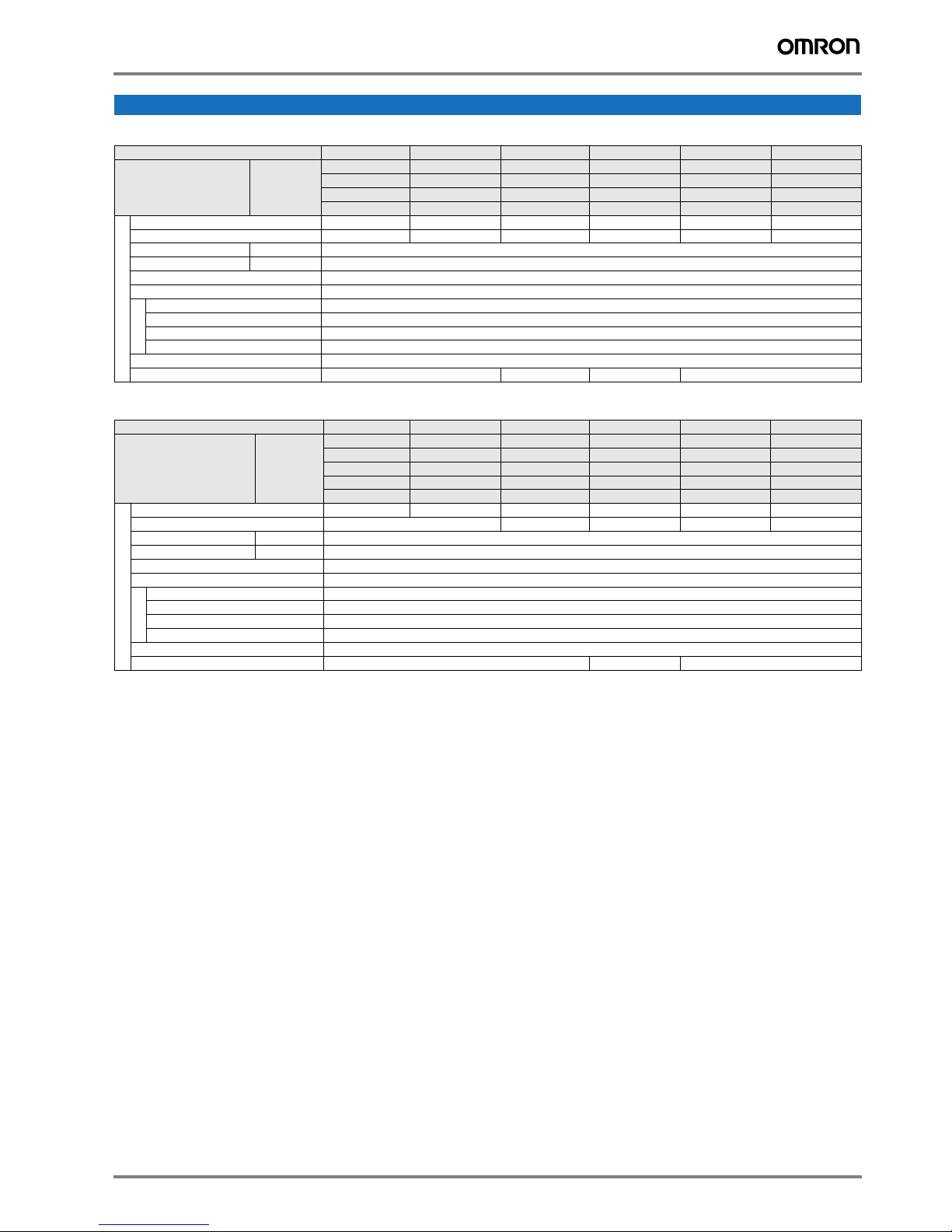

General specifications (for MECHATROLINK-II servo drives)

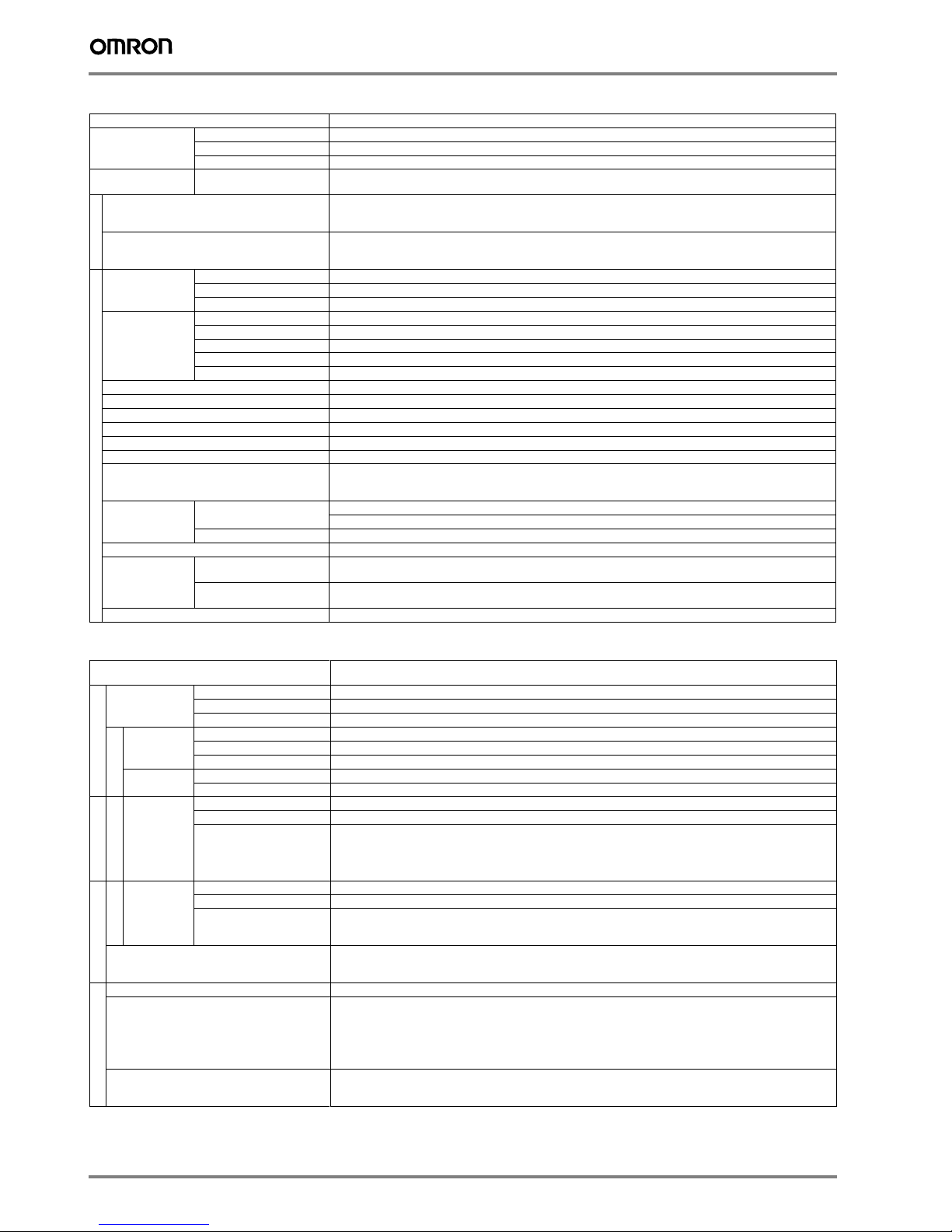

General specifications (for analog/pulse servo drives)

Control mode Position control, velocity control, torque control, full-closed control.

Performance Frequency characteristics 2 kHz

Speed zero clamp Preset velocity command can be clamped to zero by the speed zero clamp input.

soft start time setting 0 to 10 s (acceleration, deceleration can be set separately).

Command input MECHATROLINK-II

communication

MECHATROLINK-II commands (for sequence, motion, data setting/reference, monitor, adjustment and other

commands)

I/O signal

Sequence input signal - Multi-function input x 8 by parameter setting (forward/reverse drive prohibition, emergency stop, external latch,

origin proximity, forward/reverse torque limit, general purpose monitor input).

Sequence output signal It is possible to output three types of signal form incl.: brake release, servo ready, servo alarm, positioning com-

plete, motor rotation speed detection, torque limit detection, zero speed detection, speed coincidence detection,

warning, position command status, speed limit detection, alarm ouput, speed command status.

Integrated functions

USB

Communications

Interface Personal computer/ Connector mini-USB

Communications standard Compliant with USB 2.0 standard

Function Parameter setting and status monitoring

MECHATROLINK-

II communications

Communications protocol MECHATROLINK-II

Station address 41H to 51 FH (max. number of slaves: 30)

Tranmission speed 10 Mbps

Transmission cycle 1, 2 & 4 ms

Data length 17-bytes and 32-bytes

Automatic load inertia detection Automatic motor parameter setting. One parameter rigidity setting.

Dynamic brake (DB) Built-in. Operates during main power OFF, servo alarm, servo OFF or overtravel.

Regenerative processing Internal resistor included in models from 600 W to 5 kW. Regenerative resistor externally mounted (option).

Overtravel (OT) prevention function DB stop, deceleration stop or coast to stop during P-OT, N-OT operation

Encoder divider function Optional division possible

Protective functions Overcurrent, overvoltage, undervoltage, overspeed, overload, encoder error, overheat...

Analog monitor functions for supervision Analog monitor of motor speed, speed reference, torque reference, command following error, analog input...

The monitoring signals to output and their scaling can be specified with parameters.

Number of channels: 2 (Output voltage: ±10V DC)

Panel operator Display functions 2-digit 7-segment LED display shows the drive status, alarm codes, parameters...

MECHATROLINK-II communications status LED indicator (COM)

Switches 2 x rotary switches for setting the MECHATROLINK-II node address

CHARGE lamp Lits when the main circuit power supply is turned ON.

Safety terminal Functions Safety Torque OFF function to cut off the motor current and stop the motor. Output signal for failure monitoring

function.

Conformed standards EN ISO13849-1:2008 (PL- d, Performance Level d), IEC61800-5 -2:2007 (function STO, Safe Torque OFF),

EN61508:2001 (Safety Integrity Level 2, SIL2), EN954-1:1996 (CAT3).

External encoder feedback Serial signal and line-driver A-B-Z encoder for full-close control

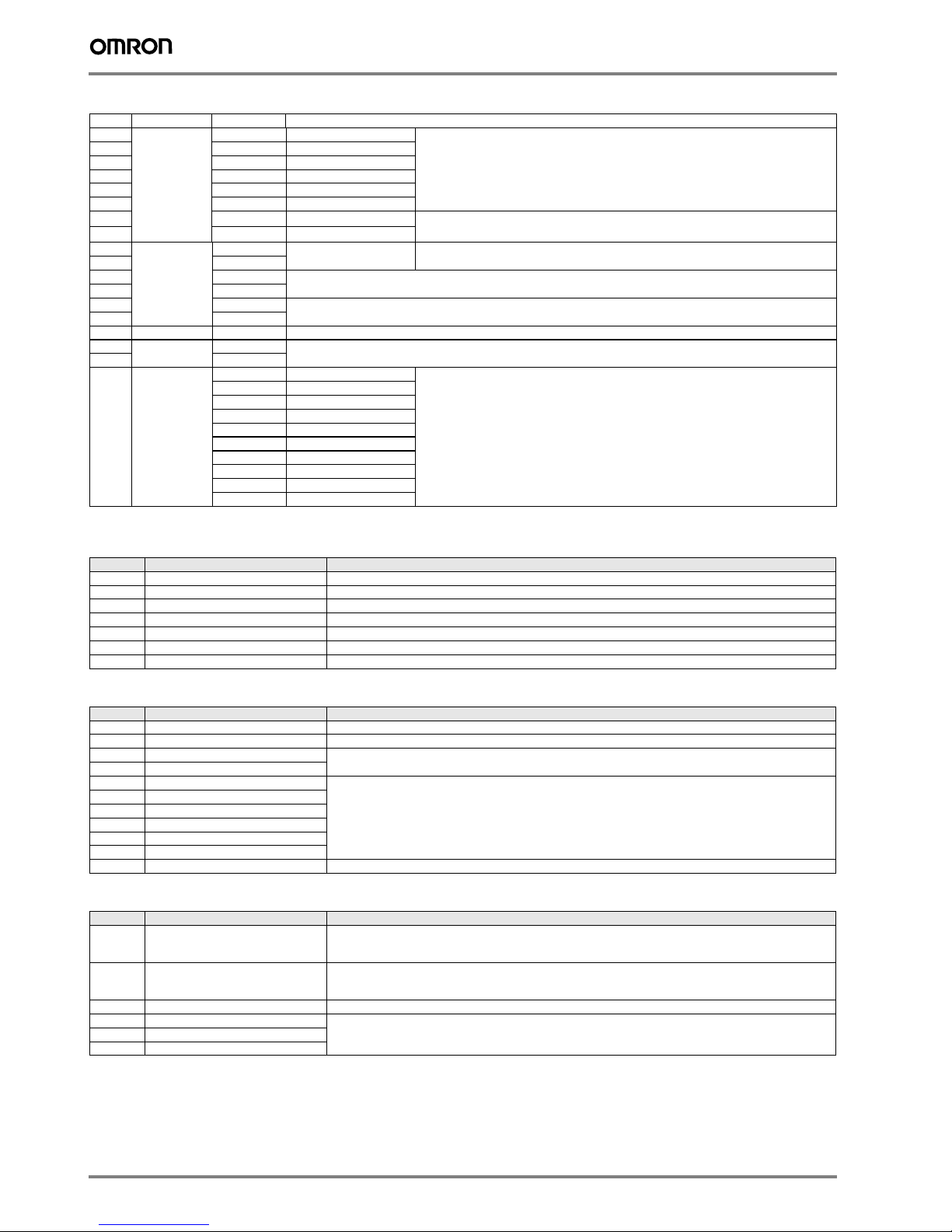

Control mode 7 modes selectables by parameter: (1) position control, (2) velocity control, (3) torque control, (4) position/velocity

control, (5) position/torque control, (6) velocity/torque control and (7) full-closed control.

Speed/torque control

Performance

Frequency characteristics 2 kHz

Speed zero clamp Preset velocity command can be clamped to zero by the speed zero clamp input.

Soft start time setting 0 to 10 s (acceleration, deceleration can be set separately). S-curve acceleration/deceleration is also available.

Input signal

Speed control Speed reference voltage 6 VDC at rated speed: set at delivery (the scale and polarity can be set by parameters)

Torque limit 3 VDC at rated torque (torque can be limited separately in positive/negative direction).

Preset speed control Preset speed is selectable from 8 internal settings by digital inputs.

Torque control Torque reference voltage 3 VDC at rated torque: set at delivery (the scale and polarity can be set by parameters).

Speed limit Speed limit can be set by parameter.

Position control

Input signal

Command

pulse

Input pulse type Sign + pulse train, 90° phase displacement 2-phase pulse (A-phase+ B-phase) or CCW/CW pulse train

Input pulse frequency 4 Mpps max. (200 Kpps max. at open collector).

Command pulse scaling

(Electronic Gear)

Applicable scaling ratio: 1/1000 - 1000

Any value of 1-2020 can be set for numerator (encoder resolution) and denominator (command pulse resolution

per motor revolution). The combination has to be within the range shown above.

Full-closed control

Input signal

Command

pulse

Input pulse type Sign + pulse train, 90° phase displacement 2-phase pulse (A-phase+ B-phase) or CCW/CW pulse train

Input pulse frequency 4 Mpps max. (200 Kpps max. at open collector).

Command pulse scaling

(Electronic Gear)

Applicable scaling ratio: 1/1000 - 1000

Any value of 1-2020 can be set for numerator (encoder resolution) and denominator (command pulse resolution).

The combination has to be within the range shown above.

External encoder scaling Applicable scaling ratio: 1/20 - 160

Any value of 1-2020 can be set for numerator (encoder resolution) and denominator (external encoder resolution

per motor revolution). The combination has to be within the range shown above.

I/O signal

Position signal output A-phase, B.phase, Z-phase line driver output and Z-phase open-collector output.

Sequence input signal - Multi-function input x 10 by parameter setting (servo ON, control mode switching, forward/reverse drive prohi-

bition, vibration filter switching, gain switching, electronic gear switching, error counter reset, pulse prohibition,

alarm reset, internal speed selection, torque limit switching, zero speed, emergency stop, inertia ratio switching,

velocity/torque command sign).

- Dedicated input x 1 (SEN: sensor ON, ABS data request).

Sequence output signal It is possible to output four types of signal form incl.: brake release, servo ready, servo alarm, positioning com-

plete, motor rotation speed detection, torque limit detection, zero speed detection, speed coincidence detection,

warning, position command status, speed limit detection, speed command status.