8

4.5 Connection and Wiring of

the DeviceNet Communications Connector - - - - - - - - - - - 4-14

4.5.1 Connector Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-14

4.5.2 DeviceNet Communications Connection Example- - - - - - - - - - - - - - 4-16

4.5.3 DeviceNet Network Configuration Restrictions - - - - - - - - - - - - - - - - 4-18

5 Parameter Settings

5.1 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.1 Outline of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.2 Parameter Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.3 Editing Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.1.4 Effective Timing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.2 Parameter Tables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.2.1 Unit Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.2.2 Origin Search Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.2.3 Machine System and Peripheral Device Parameters - - - - - - - - - - - - - 5-5

5.2.4 Speed, Acceleration, and Deceleration Parameters- - - - - - - - - - - - - - 5-6

5.2.5 Positioning Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

5.2.6 Multi-speed Positioning Parameters- - - - - - - - - - - - - - - - - - - - - - - - - 5-7

5.2.7 Notch Output Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

5.2.8 Point Table Parameter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

5.3 Parameter Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.3.1 Unit Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.3.2 Origin Search Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.3.3 Machine System and Peripheral Devices - - - - - - - - - - - - - - - - - - - - 5-22

5.3.4 Speed, Acceleration, and Deceleration - - - - - - - - - - - - - - - - - - - - - 5-26

5.3.5 Positioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-39

5.3.6 Point Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-41

5.3.7 Multi-speed Positioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-41

5.3.8 Notch Signal Output Positioning - - - - - - - - - - - - - - - - - - - - - - - - - - 5-42

6 DeviceNet Communications

6.1 Control Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

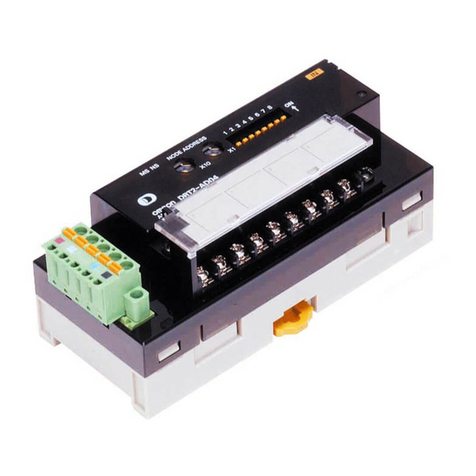

6.2 DeviceNet Switch Settings and Display - - - - - - - - - - - - - - - 6-4

6.2.1 Rotary Switch Settings for Setting Node Address - - - - - - - - - - - - - - - 6-4

6.2.2 Rotary Switch Settings for Setting Baud Rate - - - - - - - - - - - - - - - - - - 6-5

6.2.3 LED Indicators- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-5

6.3 Precautions for Communications Line Design - - - - - - - - - - - 6-6

6.3.1 Providing the Communications Power Supply- - - - - - - - - - - - - - - - - - 6-6

6.3.2 Communications Line Noise Precautions - - - - - - - - - - - - - - - - - - - - 6-16

6.4 Overview of Remote I/O and

Explicit Message Communications - - - - - - - - - - - - - - - - - 6-20

6.4.1 Remote I/O Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-20

6.4.2 Explicit Message Communications - - - - - - - - - - - - - - - - - - - - - - - - 6-20

6.5 Remote I/O Communications- - - - - - - - - - - - - - - - - - - - - - 6-21

6.5.1 Basic Block - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-21

6.5.2 General Command Bits and Status - - - - - - - - - - - - - - - - - - - - - - - - 6-22

6.5.3 Move Commands for Remote I/O Communications - - - - - - - - - - - - - 6-26

6.5.4 Set/Read Commands for Remote I/O Communications - - - - - - - - - - 6-34