Onkyo DX-C201 User manual

Other Onkyo CD Player manuals

Onkyo

Onkyo DX-C206 User manual

Onkyo

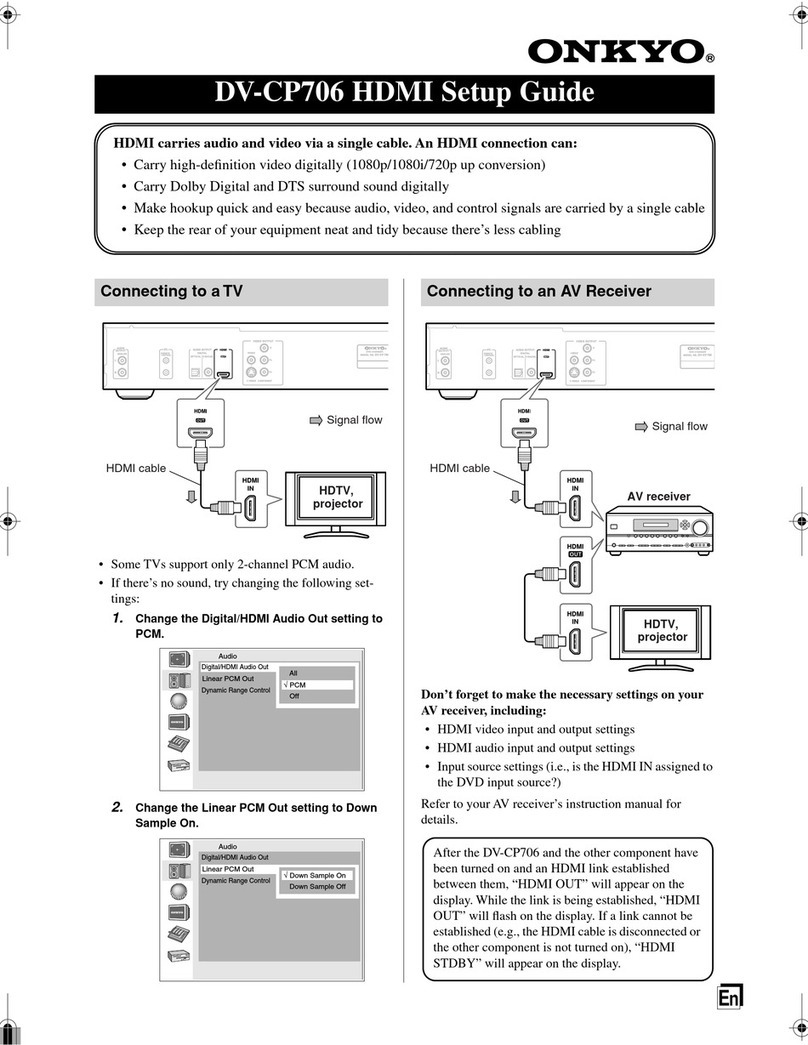

Onkyo DV-CP706 User manual

Onkyo

Onkyo DX-7911 User manual

Onkyo

Onkyo C-7000R User manual

Onkyo

Onkyo C-773 User manual

Onkyo

Onkyo DV-CP706 User manual

Onkyo

Onkyo DX-F5 User manual

Onkyo

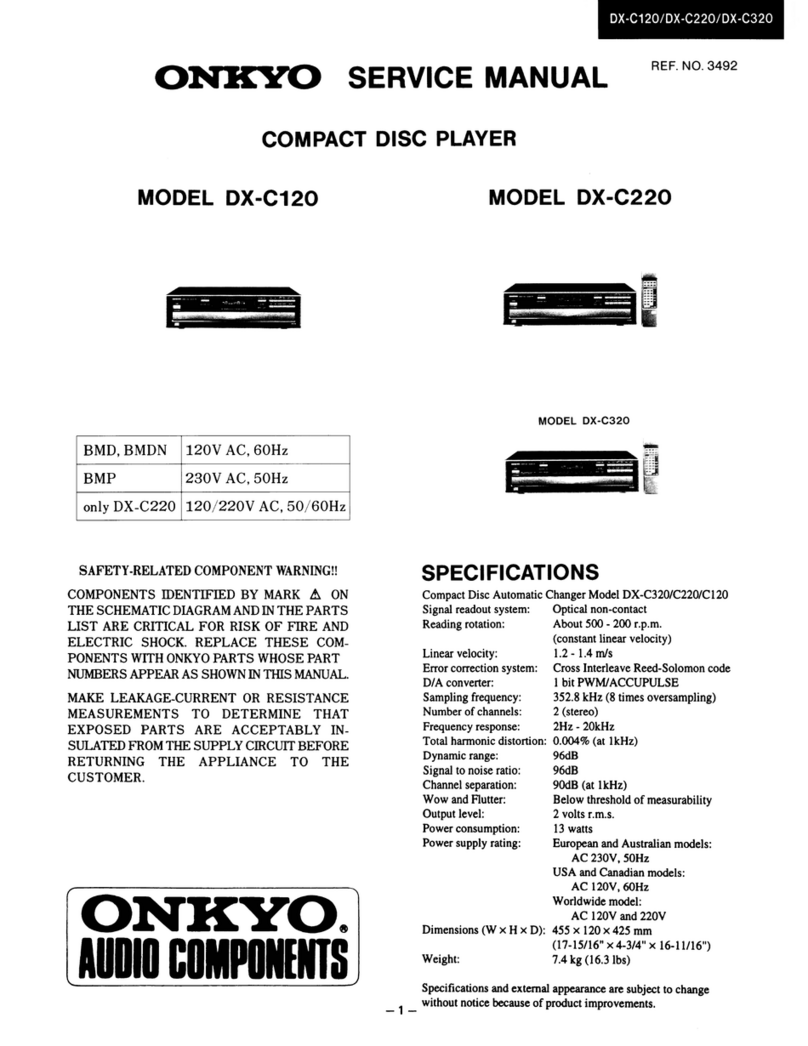

Onkyo DX-C120 User manual

Onkyo

Onkyo DXC390 - CD Changer User manual

Onkyo

Onkyo DX-5500 User manual