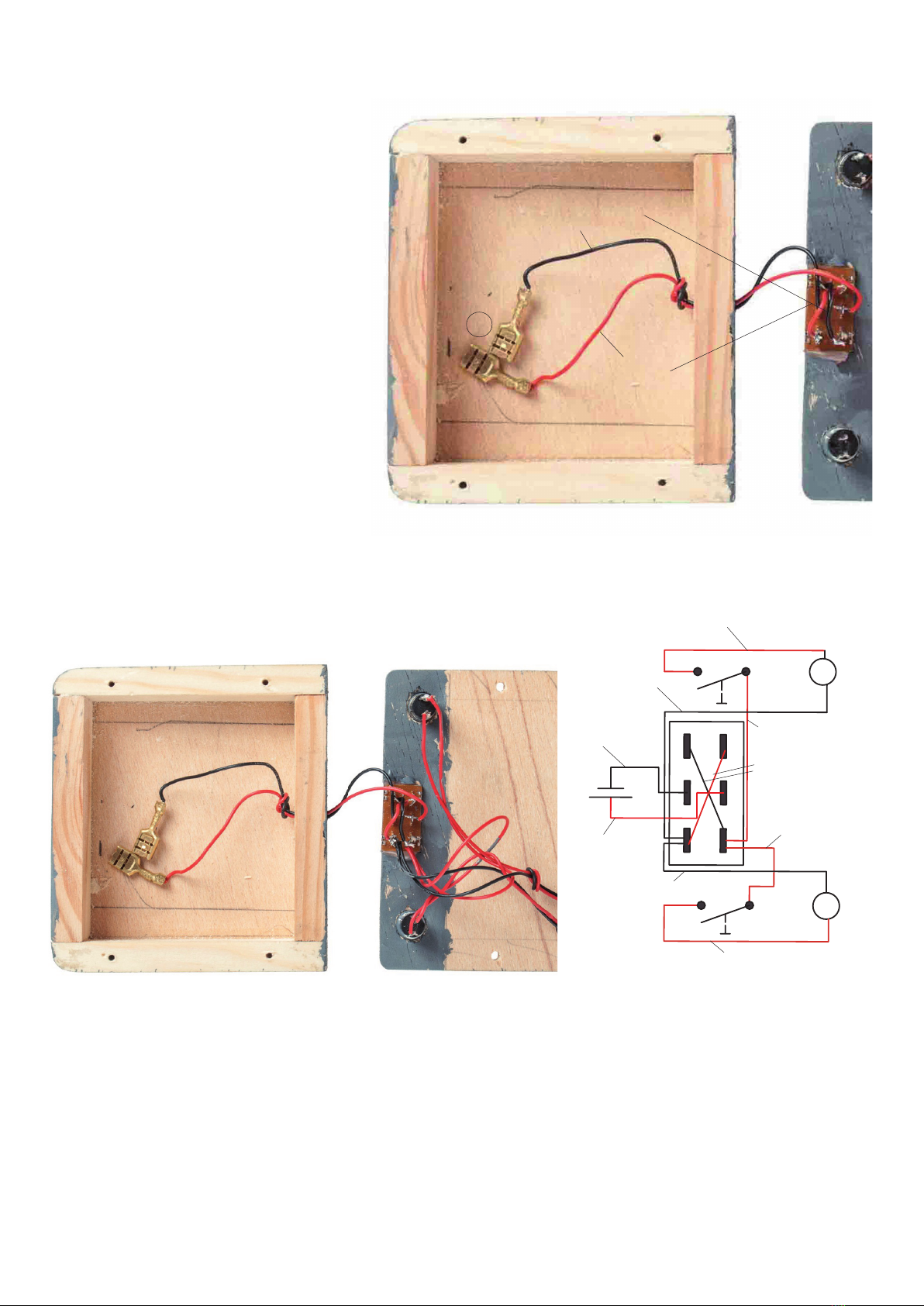

Wiring Diagram

15. Take a red and a black cable and cut a

piece of 20 mm of each wire. Now re

isolate the 4 ends and tin them. Connect

the two cables crosswise to the external

connections of the slide switch. (see

diagram; the connections of the slide

switch are the black rectangles; black

cable: from left top to right bottom;

right cable: from left bottom to right

top) Take the red and black 200mm

cable and cut them in half. Re isolate

and tin the wire ends. Furthermore take

one half of the red cable and connect

it with the middle connection of the

slide switch on the right side. After that

take one half of the black cable and

connect it with the middele connection

of the slide switch on the left side. Put

the two cables through the drilling 7d)

and knot them together in the middle.

See picture. Last but not least sold a at

receptacle (16) on each end.

red cable

black cable

16. Take one 100mm long red cable and cut it to 30mm. Re isolate and tin the ends. Now connect one end with the

front left inward facing connection of the slide switch. (In the wiring diagram it is the lowest black rectangle on

the lright side.) Connect the other end to the left push button. (It looks like a seesaw on the diagram) After that

connect one end of the remaining piece of the red cable (70mm) to the same slide switch connection. Connect

the other end with the right push button.

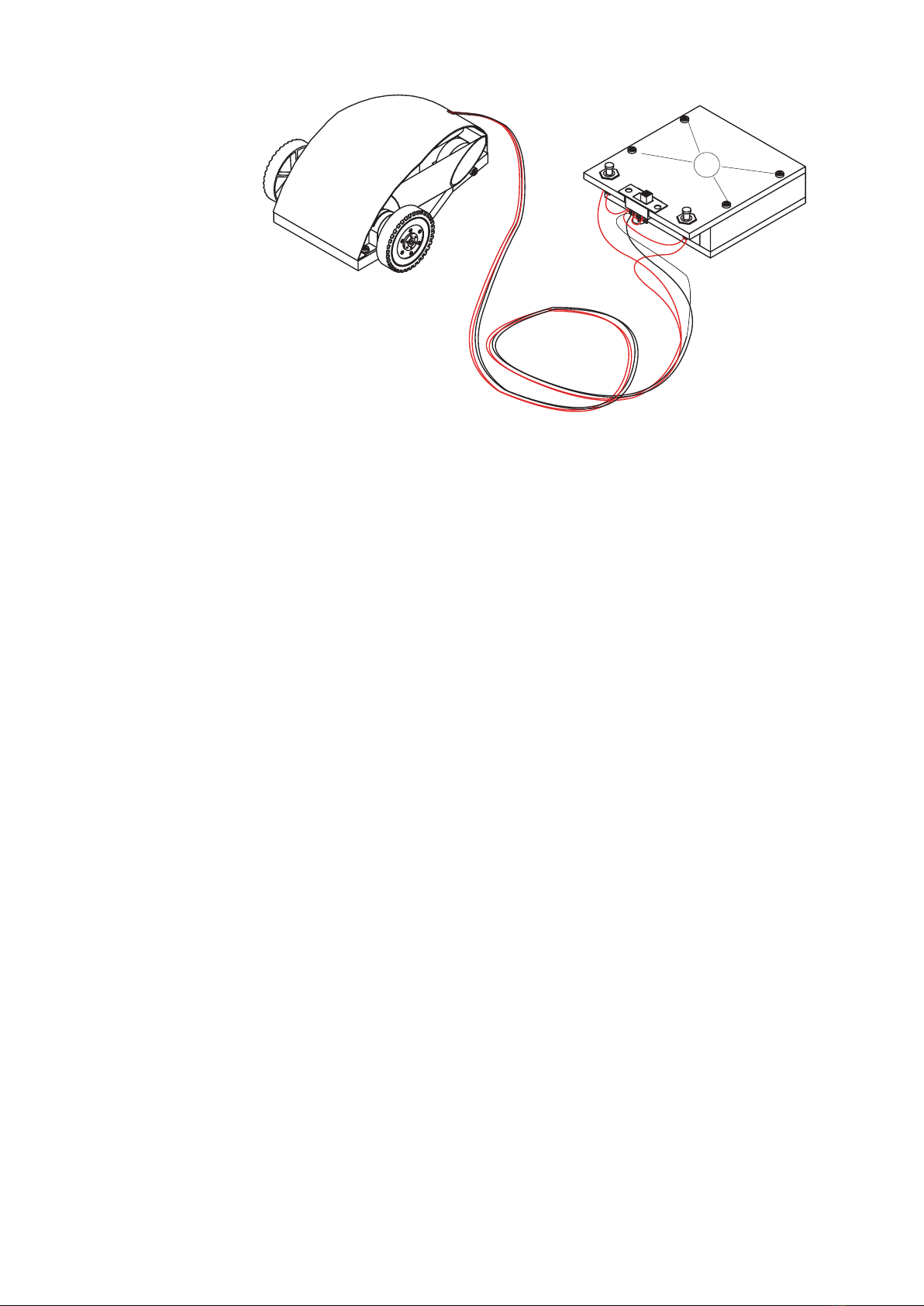

Moreover connect the two long red cables, coming from the engines, to the free connections of the push buttons

and connect the two long black cables, coming from the engines, with the left sided outwards facing slide switch

connection. (It is the lowest black rectangle on the left side) (See wiring diagram) Last put the batteries into the

control box and connect it to the at receptacles, red cable = + and black cable = -.

30mm red cable

70mm red cable

16

100mm

red cable

100mm

black cable

20mm red/black

cable

Cabling of the control:

long red cable left sided motor

long red cable right sided motor

long black cable right

sided motor

long black cable left

sided motor

left

sided

motor

right

sided

motor