1

E106061#1

106.061

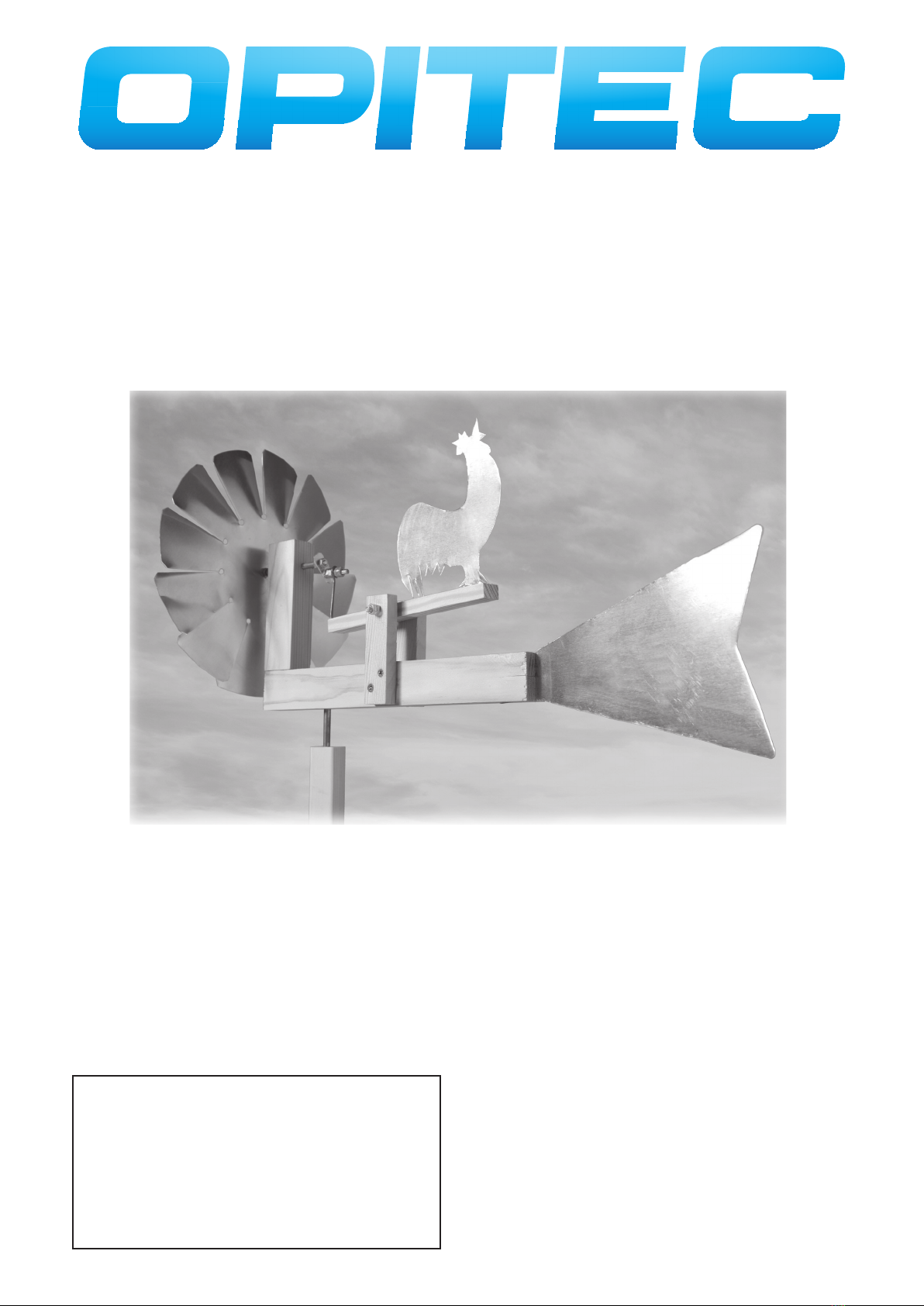

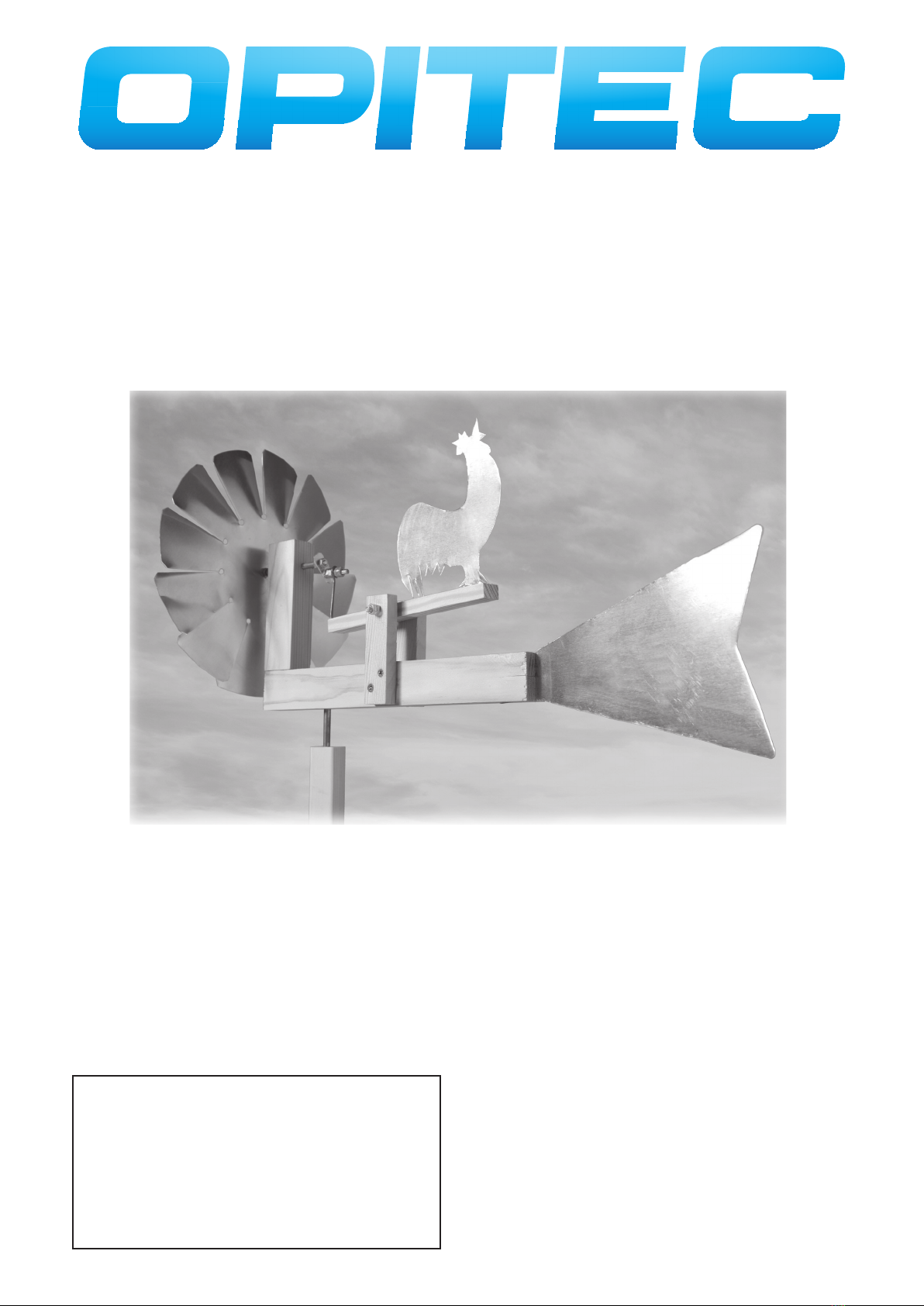

Weather vane with

wind turbine

Parts list

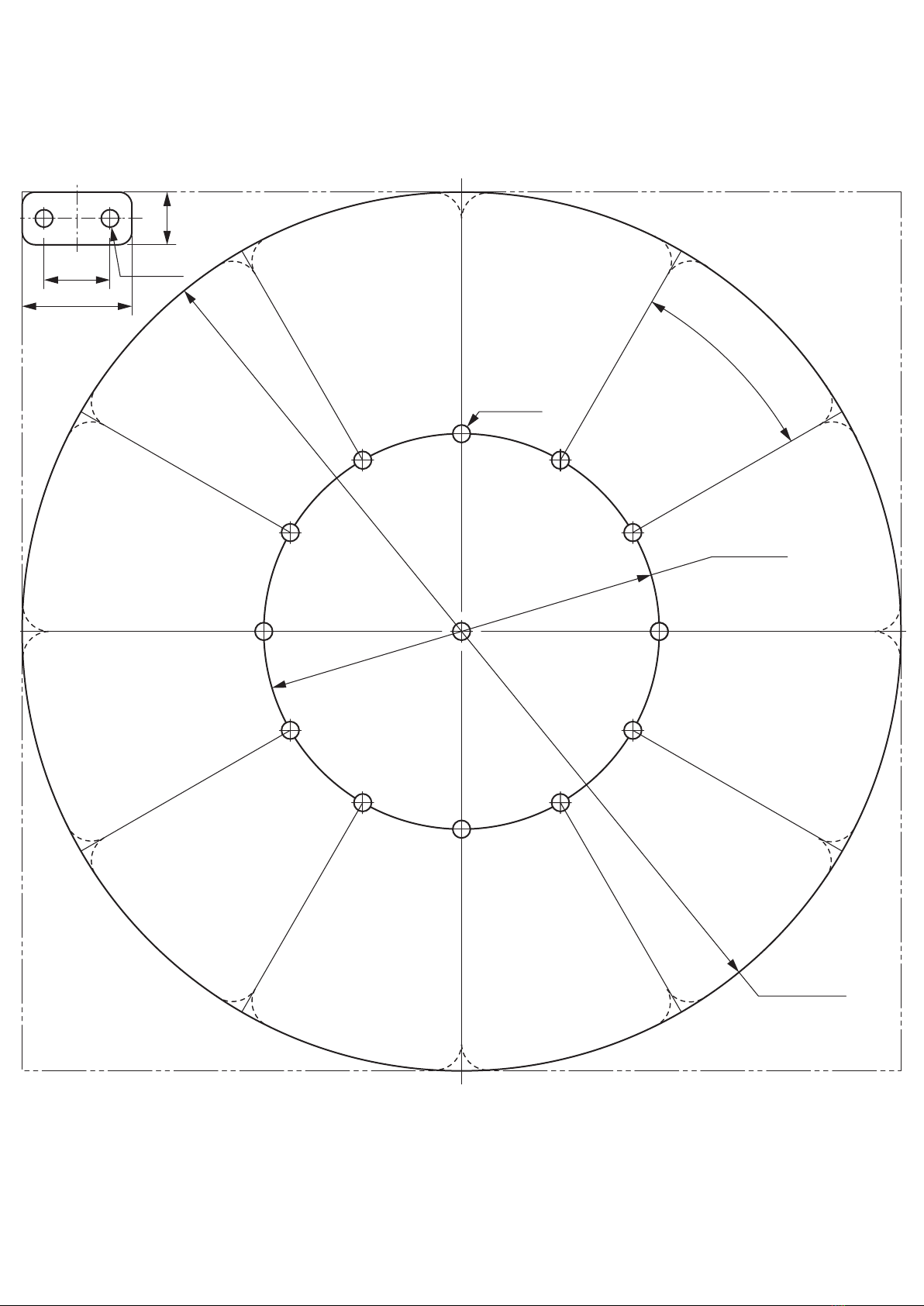

2 x Alu sheet 0,3 x 200 x 200 mm Wind turbine

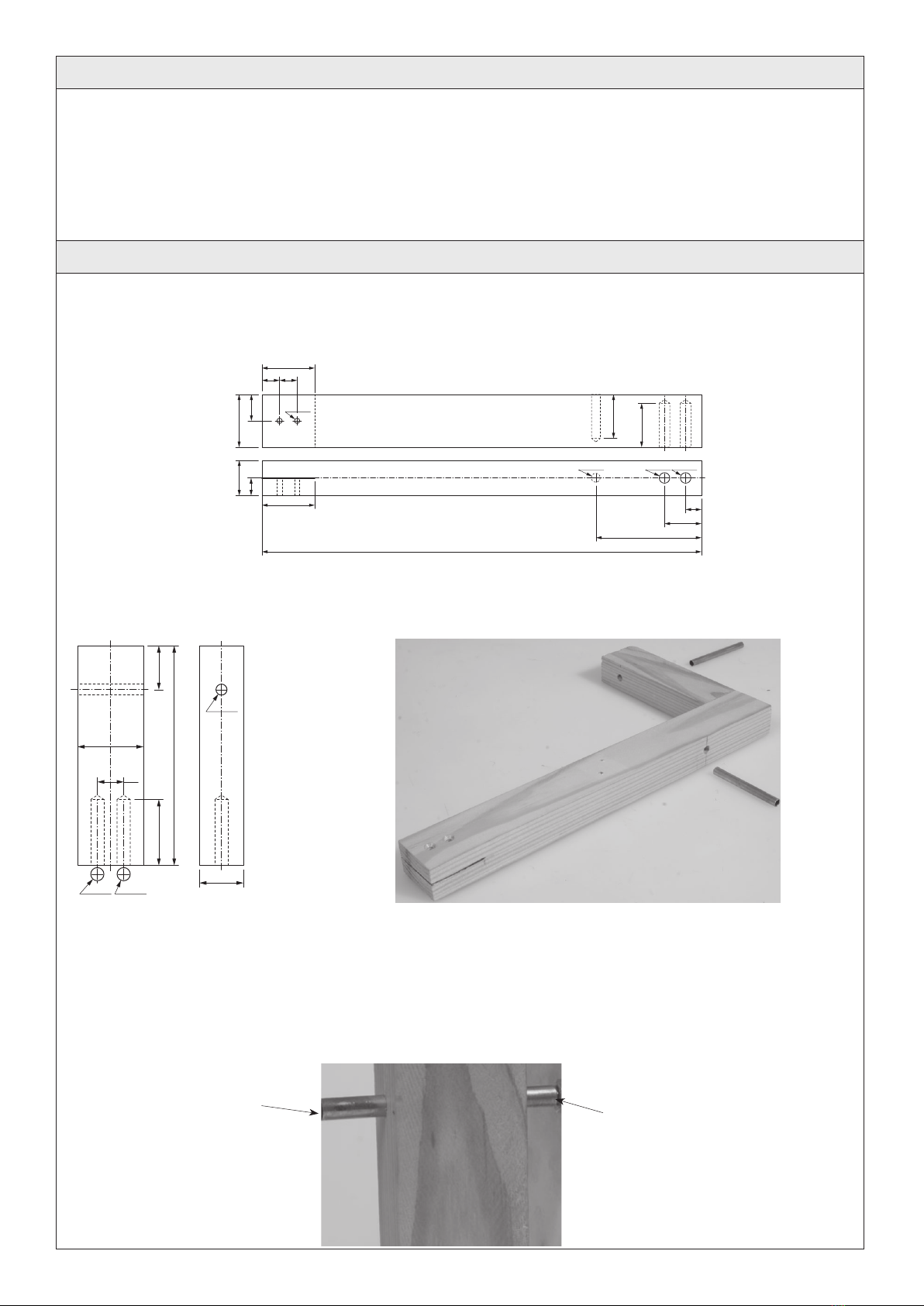

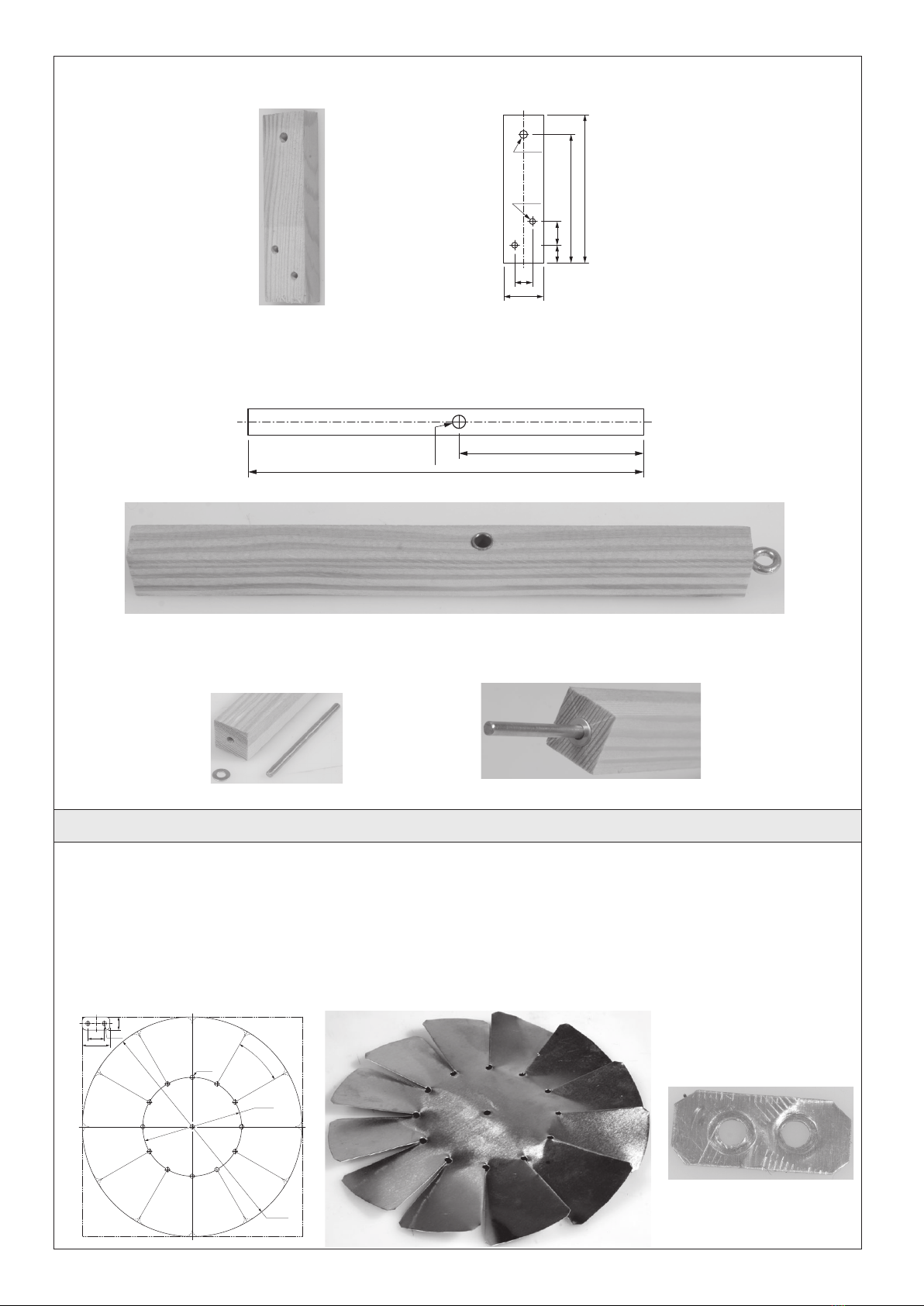

1 x Pine strip 20 x 20 x 350mm Bearing

1 x Pine strip 10 x 20 x 150mm Bearing block

1 x Pine strip 10 x 15 x 150mm Base

1 x Pine strip 20 x 30 x 250mm Frame

1 x Pine strip 20 x 30x 100mm Frame

1 x Brass tube 5dia/0,5 x 245mm Bush

10 x Nuts M4

10 x Washers M4

1 x Screw eye 12mm

2 x Pine dowel dia 6 x 50mm Dowel

1 x Brass rod dia 4 x 68mm Bearing

1 x Welding rod dia 2 x 100mm Rod

1 x Machine screw M4 x 70mm

1 x Machine screw M4 x 50mm

1 x Machine screw M4 x 20mm

2 x Grub screws 2,9 x 9,5mm

6 x Wood screws 3 x 20mm

Necessary tools and equipment

Ruler, compass, pencil

Sandpaper

Metal shears

Spanner (M4)

Screwdrivers slot and cross

Drills 3mm dia + 4 + 5mm

Hacksaw

File

Paint & brush

Please Note

The OPITEC range of projects is not intended as play

toys for young children.They are teaching aids for

young people learning the skills of Craft, Design and

Technolo- gy.These projects should only be underta-

ken and tested with the guidance of a fully qualified

adult. The finished projects are not suitable to give to

children under 3 years old. Some parts can be swallo-

wed. Dan- ger of suffocation!