Fire Protection | Data sheet No. 43104 | Version 02-2016 | 1| 8

Control unit STG 1.2

for DRM ceiling smoke detector/DKM manual call point – bus compatible

Technical data

Supply voltage: 24 V AC +/-10%

24 V DC +15%/ -10%

Power consumption: 250 mA (normal operation)

Imax 2.5 A (alarm – 20 detectors)

Imax 6.2 A (0.02 s short circuit)

Relay outputs:

Alarm: 1 changeover contact

240 V AC/30 V DC, 8 A

1 NC

240 V AC/30 V DC, 8 A

Contamination: 1 changeover contact

400 V AC/300 V DC, 6 A

Failure: 1 changeover contact

400 V AC/300 V DC, 6 A

Service: 1 changeover contact

(service mode) 400 V AC/300 V DC, 6 A

Notications:

Display: Plain text display status

DRM/ DKM, conguration

Alarm: red LED

Contamination: yellow LED

Failure: yellow LED

Operation: green LED

Housing: plastic ABS

Dimensions (W x H x D): 160 x 85 x 50 mm

Installation: DIN-rail, panel

Protection class: IP20

Ambient temperature: 0 °C to 50 °C

Connection: spring terminals 0.5 – 2.5 mm²

• Can connect up to 99 DRM 3.3 or DRM 3.3-N

ceiling smoke detectors/ DKM 3.3 manual call

points

• Possible to query each detector as to status

and contamination

• Large LCD display and 4 additional LEDs

• RS485 Mod-Bus interface for informal

transmissions to the building management

system (BMS)

• 4 changeover contacts for alarm, failure,

service and contamination

• 1 NC for alarm

• Monitoring for short circuits and cable breaks

Function

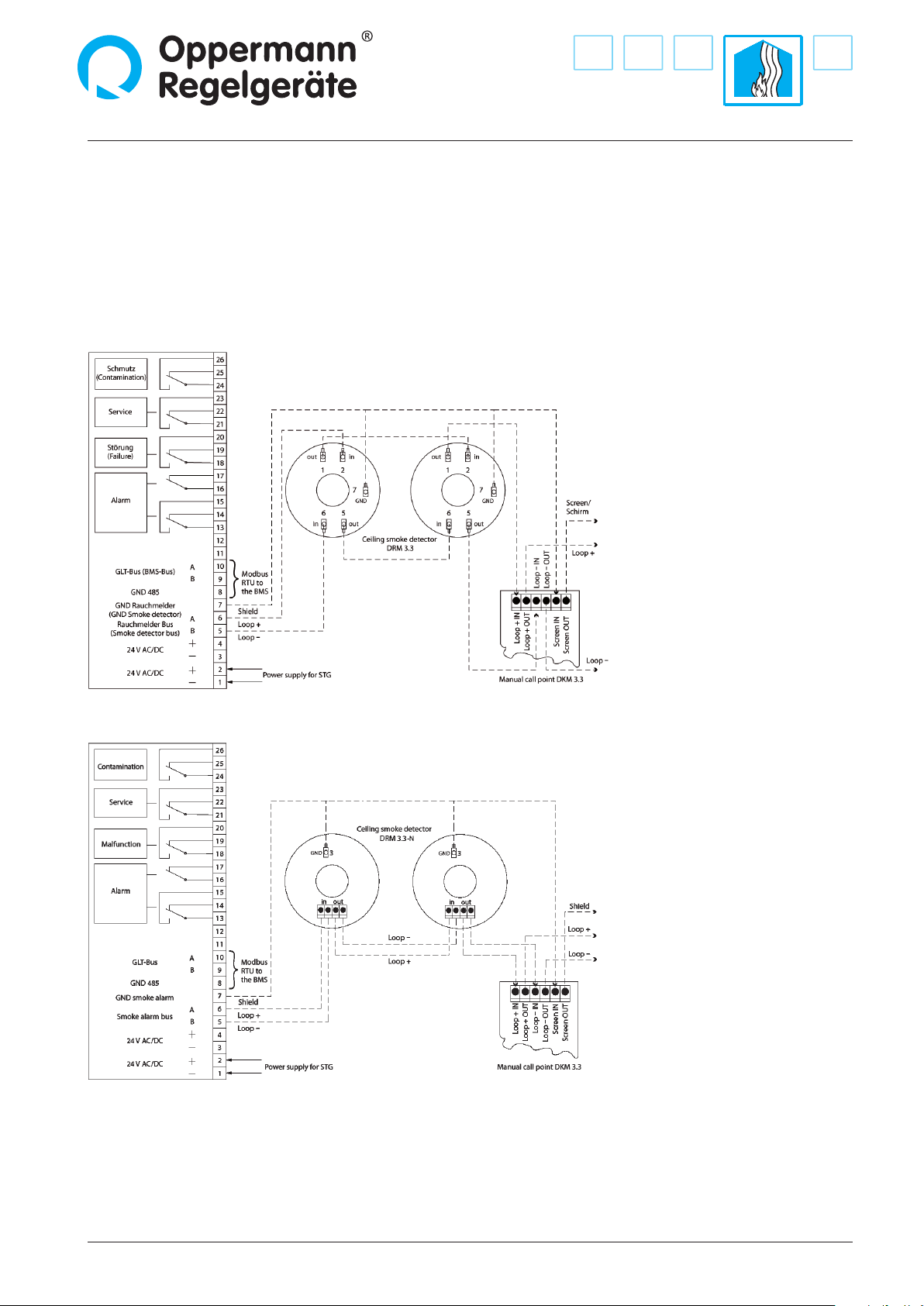

Up to 99 type DRM 3.3 or DRM 3.3-N/DKM 3.3 ceiling smoke

detector or manual call points can be monitored by the STG con-

trol unit. The STG communicates with its connected detectors

by way of their security monitored system ring buses. Smoke

alarms, failure and contamination messages are all forwarded

from the detectors to the STG and shown on a display. This

makes it possible for a technician or custodian to supervise all

the connected detectors at a glance. The STG has one changeo-

ver relay each for alarm, contamination, failure and service mode

signalling. With the alarm message there is a relay available

which serves as an NC contact. With this relay the messages can

be reported to a central building management system (BMS).

The STG 1.2 additionally has an RS-485 interface to the BMS,

which also exports all of this data including the status of indivi-

dual detectors via a Modbus RTU protocol. With this interface it

is also possible to evaluate the STG via PLC control or a PC.

Important note: In addition, please note the separate

DRM/ DKM data sheets.

If an alarm occurs at one or more connected detectors, the red

LED lights up on the STG, a message is issued to the STG display,

and the corresponding NC contact and changeover contact at

the STG drop out. By pressing the reset button the relay contact

can be restored, but the corresponding alarm must be termina-

ted/disabled rst. In case of failure, connection problems as well

as contamination of one or more of the detectors, the yellow

contamination LED on the STG lights up and the corresponding

changeover relay of the STG drops out. If no connection to a

duct smoke detector can be made, a failure message appears

on the STG. If a new detector is connected in the service mode,

a corresponding message appears on the display. If the STG is

in service mode the service relay drops out. Failure and alarm

messages of the connected detectors must be acknowledged

once more through the STG“alarm /reset” button.