4

Introduction

Since the introduction of the first timing belt at the end of the 40’s,

this type of drive element has gained in importance for the

synchronous transmission of torque and power. The non-slip timing

belt has been successfully employed in many standard drives and

has provided economical design solutions in every sector of

mechanical engineering.

The position that the timing belt occupies today is due to the

development of tooth profiles and belt design. The Optibelt ZRM/

ZRP/ZRL single and double-section polyurethane timing belts are a

result of this progress. The properties specific to the polyurethane,

offer the following advantages:

●High resistance to abrasion

●Good to very good resistance to oil, grease and a

number of aggressive chemicals

●Colour fast

●Simple to weld, for attaching cleats and joining

endless to make belts of any length

●High resistance to tooth shear

●Good thermal tolerance (–30 °C to +80 °C)

●Good electrical insulation properties using poly-

urethane with Aramid tension cord

●Ageing resistant

●Ozone and UV resistant

Apart from the higher noise level at high belt speeds when

compared to V-belt drives, the timing belt has all of the advantages

of other drive mechanisms.

●Synchronous speed transmission, high angle and

positional accuracy due to the low-stretch tension

member and to the positive pulley/belt interlock.

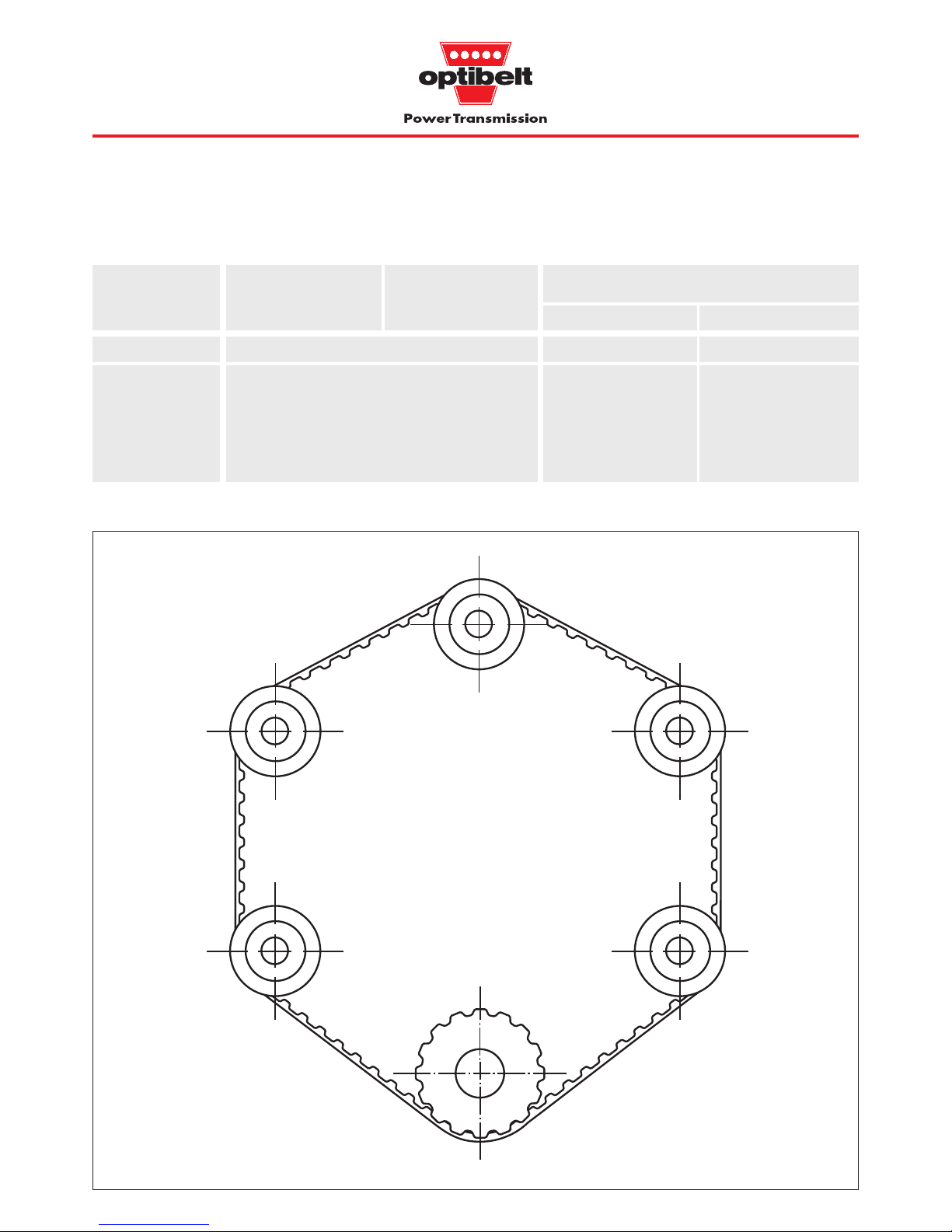

●Double section belts permit multi-pulley arrange-

ments and contra-rotating pulleys.

●Belt flexibility allows high drive ratios requiring

minimum space.

●Low belt specific mass enables high belt speeds.

●Low-stretch tension cord means zero maintenance.

●High drive efficiency due to belt flexibility and lack

of slip.

●The low drive tension allows the use of smaller drive

bearings.

●No drive lubricant necessary, thus the drive is envi-

ronmentally friendly.

●Durable belt components ensure longer belt life.

1 Product Description

1.1 Construction

In addition to the features of the standard synchronised drive, the

Optibelt ZRM/ZRP/ZRL timing belts offer the additional advan-

tages of polyurethane, as shown above, as a contribution to the

economical solution of design problems.

Top surface

Tension cord

Tooth

Base

Construction: Timing belts

Fig.1.1: Timing belts

a) Top surface

The top surface of the belt is polyurethane. Its function is to hold and

support the tension cord. This abrasion-proof, thin and extremely

flexible layer also protects the tension cord against wear and the

effects of ambient conditions.

b) Tension cord

The tension cord of the endless Optibelt ZRM/ZRP timing belt is

spirally wound steel cord. The teeth, base and top surface form a

unit so that the tension cord is enclosed in polyurethane.

The extremely strong, low stretch tension cord has a very small

cross section.

The open-ended Optibelt ZRL-M belting has parallel steel or

Aramid tension cords. This is also the case with the joined endless

Optibelt ZRL-V timing belt.

c) Teeth and base

The polyurethane teeth transfer power between the pulley teeth and

the belt tension cord, whilst the polyurethane base cushions the

tension cord against the abrasion from the top of the pulley teeth

(see Fig. 1.3).

The durable, shear resistant belt teeth are so formed and arranged

as to engage with the matching pulley with minimum friction and

maximum precision. When six teeth on the belt type ZRL-V, and

twelve teeth or more on the ZRM, ZRP and ZRL-M belts are in mesh

with the small pulley at any one time, their shear resistance exceeds

the maximum permitted circumferential force of the timing belt.