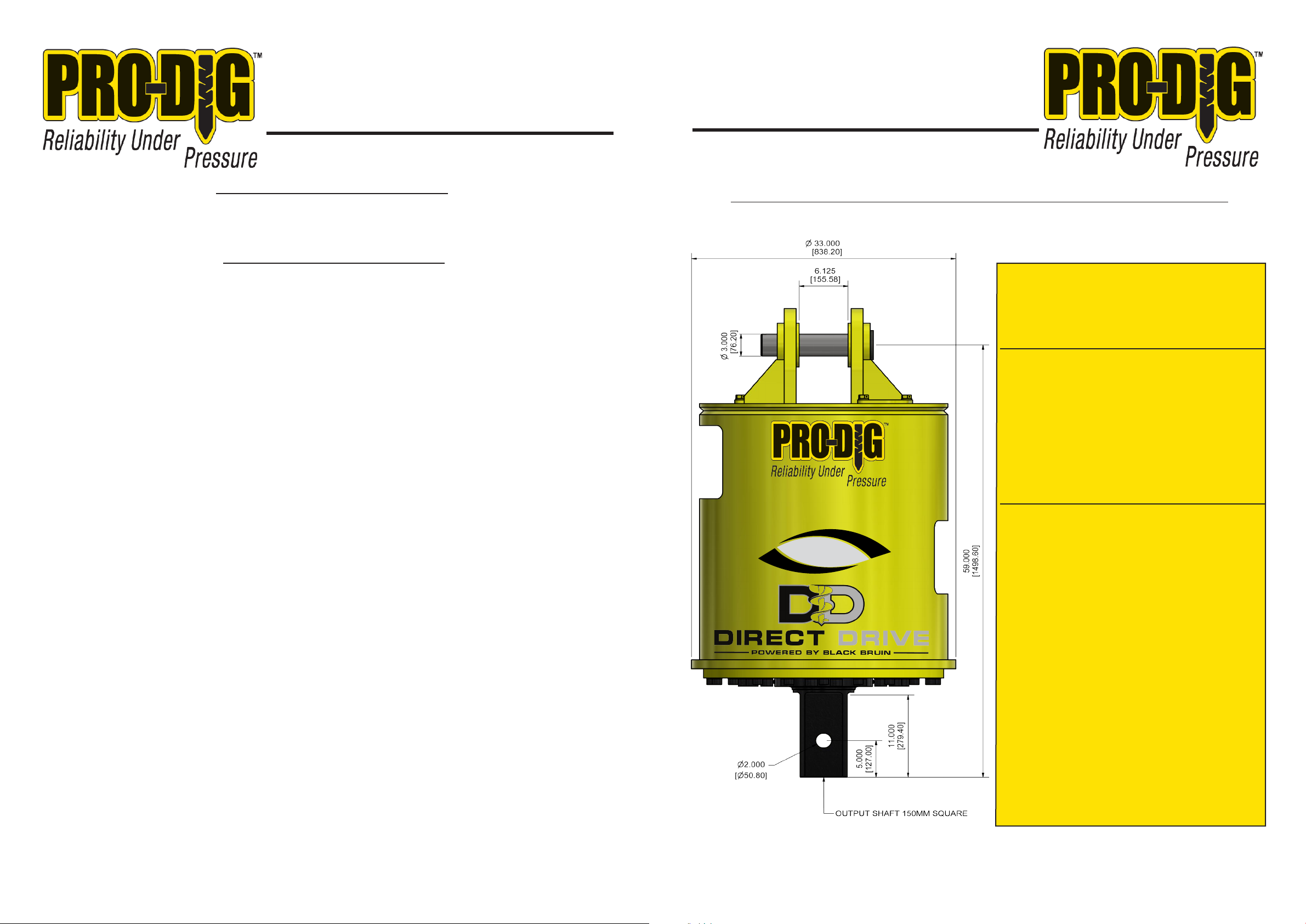

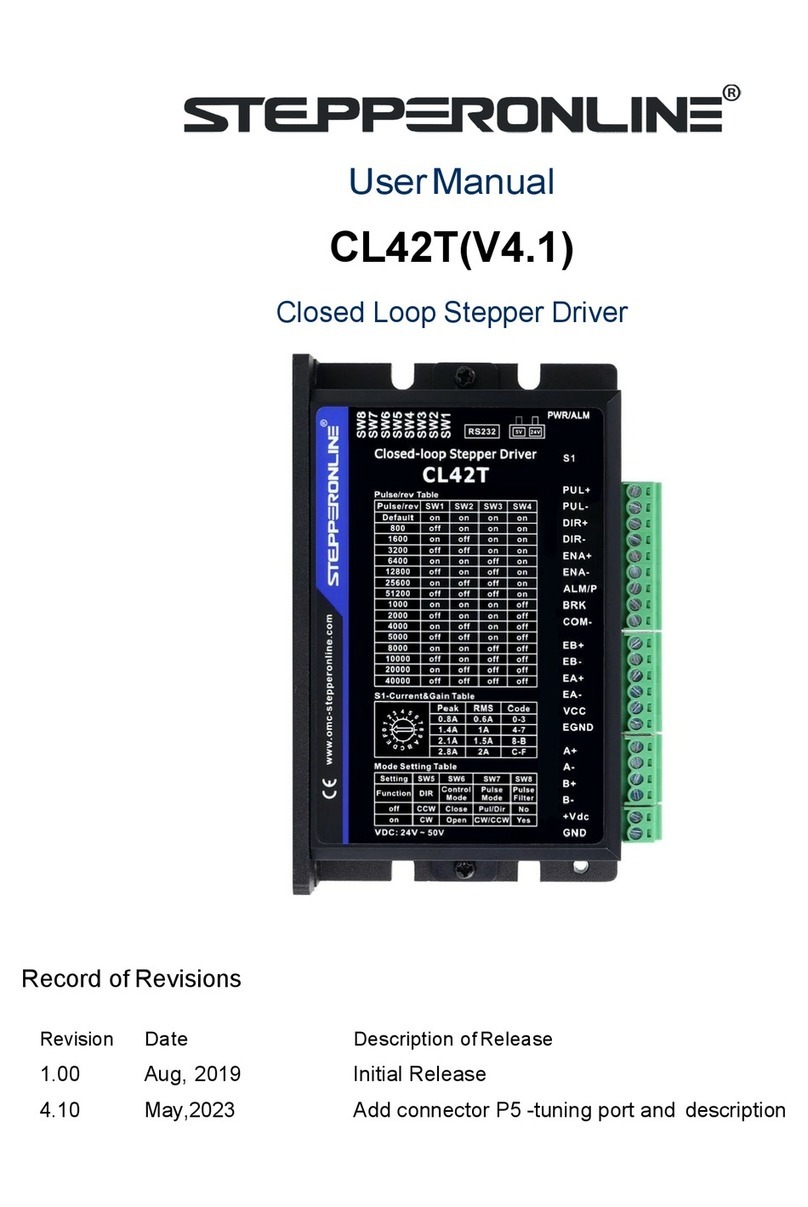

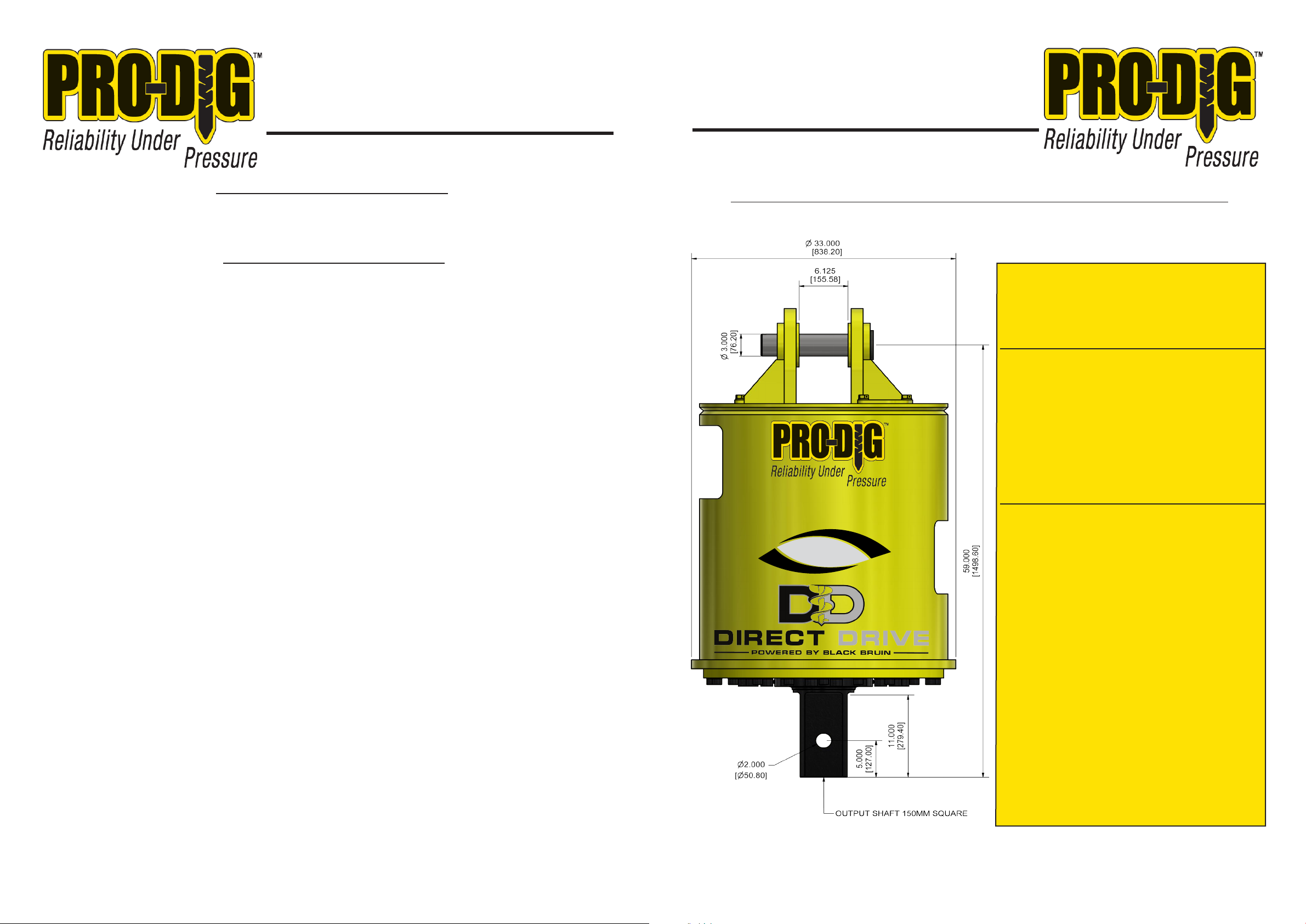

PartNumber DDT75K

Min.HydraulicFlow 20GPM(76LPM)

Max.HydraulicFlow 150GPM(568LPM)

Max.ContinuousPressure 6500PSI(448Bar)

OutputShaft 150mmsquare

OUTPUT SPEED

FLOW LOWSPEED HIGHSPEED

GPM(LPM) RPM RPM

20(76) 4 8

40(151) 8 16

60(227) 12 24

80(303) 16 32

100(379) 20 40

120(454) 24 48

140(530) 28 56

150(568) 30 60

OUTPUT TORQUE

PRESSURE HIGHSPEED LOWSPEED

PSI(BAR) ft-lbs(Nm) ft-lbs(Nm)

500(34) 3822(5182 7644(10364)

750(52) 5733(7773) 11466(15546)

1000(69) 7644(10364) 15288(20728)

1250(86) 9555(12955) 19111(25911)

1500(103) 11466(15546) 22933(31093)

1750(121) 13377(18137) 26755(36275)

2000(138) 15288(20728) 30577(41457)

2250(155) 17200(23319) 34399(46639)

2500(172) 19111(25911) 38221(51821)

2750(189) 21022(28502) 42043(57003)

3000(207) 22933(31093) 45865(62185)

3250(224) 24844(33684) 49688(67367)

3500(241) 26755(36275) 53510(72550)

3750(258) 28666(38866) 57332(777732)

4000(276) 30577(41457) 61154(82914)

4250(293) 32488(44048) 64976(88096)

4500(310) 34399(46639) 68798(93278)

4750(327) 36310(49230) 72620(98460)

5000(345) 38221(51821) 76442(103642)

Note: 1 Ftlb = 1.356 Nm

Note: PRO-DIG®continually looks for new ways to improve its products.

erefore, PRO-DIG®reserves the right to make changes to our products and

specications without notice.

OPERATING PROCEDURES

SPECIFICATIONS/COMPONENT AND CONTROL LOCATIONS

SAFETY DECAL LOCATIONS

is unit comes equipped with all safety decals in place. ey are designed to help you safely operate your

unit. Read and follow all safety decals.

Before operating always ensure that the PRO-DIG™Auger

Drive and auger or anchor are connected correctly to the

parent machine.

DRILLING OPERATIONS

1. Tobegindrilling,positiontheaugeroranchoronthe

groundinthedesiredlocation.Engagetheparentma-

chinesauxiliaryhydraulicstorotatetheaugeroranchor

inaclockwisedirection.

2. Lowertheparentmachinesarm(s)toengagetheauger

oranchorintotheground.Useonlyenoughdownpres-

suretoassurepositivepenetrationoftheauger.Easeup

onthedownpressureiftheaugerrotationslowsdown

drasticallyorstalls.Excessivedownpressurewillcause

theaugertostallfrequently.

Note: Do not continually stall the PRO-DIG™Auger

Drive! Continued stalling may cause excessive heat-

ing of the hydraulic system and possible damage to the

PRO-DIG™Auger Drive.

3. Astheaugeroranchordigsintheground,theparent

machinesarm(s)orboommaytravelthroughanarc.This

meanstheoperatormayneedtocontinuallyreposition

themachinetoensureverticalapplicationoftheaugeror

anchor.

4. Whentheaugerhaspenetratedthegroundabout24”

(610mm),raisetheaugerfromtheholetocleanoutthe

loosematerial.

5. Oncetherequiredholedepthisreached,allowtheauger

toturnafewsecondsatthisdepthtocleanthehole.

6. Stoprotationoftheaugerandraisetheaugeroutofthe

hole.Swingtheaugerawayfromthenewlydrilledhole.

Spintheloosematerialofftheauger.

Note: Do not reverse the auger rotation while the au-

ger is still in the hole. e loose material will back ll

the hole.

7. Ifnecessary,repeatsteps2through3toobtainacleaner

hole.

OPERATIONS TO AVOID

1. Insomesoilconditionsorwhenexcessivedownpressure

isapplied,theaugermayscrewitselfintotheground.

Thiscancausetheaugertobecomestuckcausingthe

PRO-DIG™AugerDrivetostall.Ifthissituationoccurs,

reversetheaugerrotationandslowlyraisetheauger

fromthehole.

2. Iftheaugerbecomeslodgedunderrocks,treeroots,

orotherlargeobstructions,donotattempttoraisethe

augeroutoftheground.SeeStep1ofthissectionto

relievetheauger.

3. Avoidexcessivesideloading.Thiscancausedamageto

boththePRO-DIG™AugerDriveandtheauger.

4. Keepallaugerteethandpilotbitsingoodcondition.

Avoidusingdamagedteethandholders.

• Followingoperation,orwhenunhooking,stop,set

brakes,disengagepowerdrives,shutoffengine,and

removetheignitionkey.

• Storetheunitinandwayfromhumanactivity.

• Beforelongtermstorage,washtheunitwithmild

detergentandwatertoremoveanydebrisandgrime.

• Donotpermitchildrentoplayonoraroundthe

storedarea.

• Protecttheshaftsandportswithagreaseorrust-

inhibitor.

• Greasebearingseals.

• Checkandtightenallbolts,nutsandscrews.Paintis

availablefromyourAuthorizedServiceDealer.

• Whenstoringtheunitforanylengthoftimebesure

theunitisstoredwithcleangearoil.

WWW.PRO-DIG-USA.COM 785.856.2661

6 7

DDT75K

DDT75K