Optimum RT 100 CN User manual

OPTIMUM

MASCHINEN - GERMANY

25.8.09 Page 1Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009

GB

Conversion instruction

Version 1.1.1

Adapter kit

RT 100/ 150 CNC

Keep for future reference!

Illustr. 0-1: RT100

OPTIMUM

MASCHINEN - GERMANY

25.8.09Page 2 Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009 GB

Contents

1 Safety warnings (warning notes)

1.1 Classification of hazards......................................................................................................... 3

1.2 Proper use .............................................................................................................................. 4

1.3 Required auxiliary material...................................................................................................... 4

2 Packing list RT 100 CNC

3 Packing list RT 150 CNC

4 Assembly RT 100/ 150 CNC

4.1 Assembly on the RT................................................................................................................ 7

5 Installation of the step motors

5.1 Wiring.................................................................................................................................... 11

6 RT CNC

7 Appendix

7.1 Copyright............................................................................................................................... 16

7.2 Terminology/Glossary........................................................................................................... 16

7.3 Liability claims for defects / warranty .................................................................................... 17

7.4 Note regarding disposal / options to reuse:........................................................................... 17

7.5 Disposal ................................................................................................................................ 19

7.6 RoHS , 2002/95/CE............................................................................................................... 19

7.7 Product follow-up .................................................................................................................. 20

OPTIMUM

MASCHINEN - GERMANY

Safety warnings (warning notes)

25.8.09 Page 3Safety warnings (warning notes) Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009

GB

1 Safety warnings (warning notes)

1.1 Classification of hazards

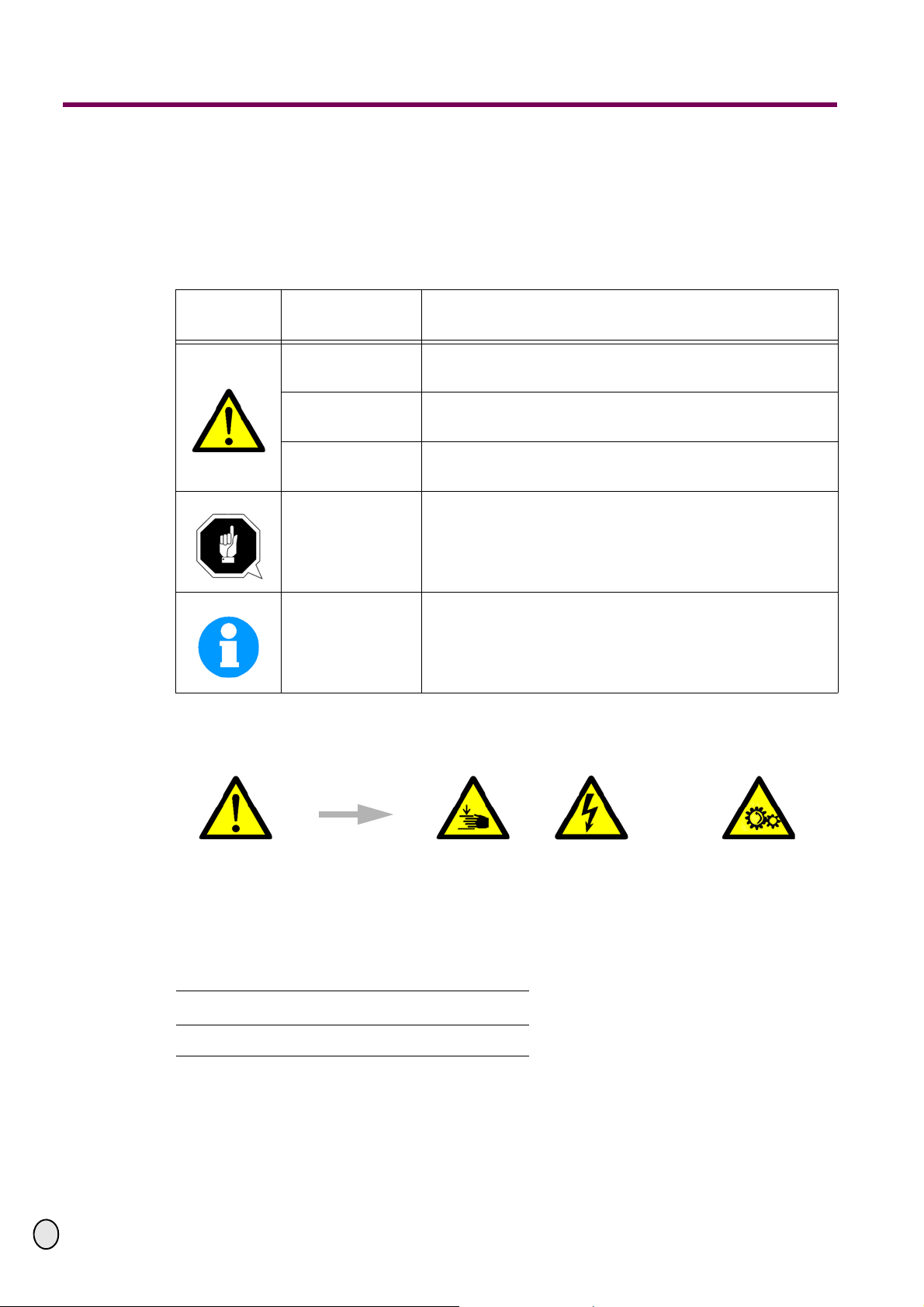

We classify the safety warnings into various levels. The table below gives an overview of the

classification of symbols (pictograms) and warnings for the specific danger and its (possible)

consequences.

1.1.1 Glossary of symbols

Pictogram Alarm expres-

sion Definition/Consequences

DANGER! Imminent danger that will cause serious injury or death to

personnel.

WARNING! Risk: A danger that might cause serious injury or death to

personnel.

CAUTION! Danger of unsafe procedure that might cause injury to

personnel or damage to property.

ATTENTION!

Situation that could cause damage to the machine and

product and other types of damage.

No risk of injury to personnel.

INFORMATION

Application tips and other important or useful information

and notes.

No dangerous or harmful consequences for personnel or

objects.

In the case of specific dangers, we replace the pictogram by

or

General dan-

ger with a warning

of injuries to

hands, hazardous

electrical

voltage,

rotating parts.

gives additional advices

enumerations

Safety warnings (warning notes)

OPTIMUM

MASCHINEN - GERMANY

25.8.09Page 4 Safety warnings (warning notes) Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009 GB

1.2 Proper use

WARNING!

In the event of improper use of the add-on pieces, it

• will endanger the user,

• will endanger the machine and other material property of the operator or user,

• may affect proper operation of the machine.

The attachment parts as conversion kit are provided for engine driven milling works of your

machine.

Improper

use! The milling machine with the adapter kit must only be placed and operated in dry and ventilated

rooms.

The handwheels on the driven axis need to be disassembled for safety reasons.

If the adapter kit is used in any way other than described above or modified without approval or

the company Optimum Maschinen Germany GmbH, the adapter kit is no longer properly used.

We do not take liability for any damage caused by improper use.

We would like to stress that any modifications to the construction, or technical or technological

modifications that have not been authorized by Optimum Maschinen GmbH will also render the

guarantee null and void.

1.3 Required auxiliary material

Means of shaft lock-down device "Loctite 648, join the shaft".

The designation of the parts in the assembly description corresponds to the numbering of the

packing list.

In order to degrease the shaft, a cleaner for brakes or a corresponding cleaning agent is

required.

Required tools:

Allen key

OPTIMUM

MASCHINEN - GERMANY

Packing list RT 100 CNC

25.8.09 Page 5Packing list RT 100 CNC Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009

GB

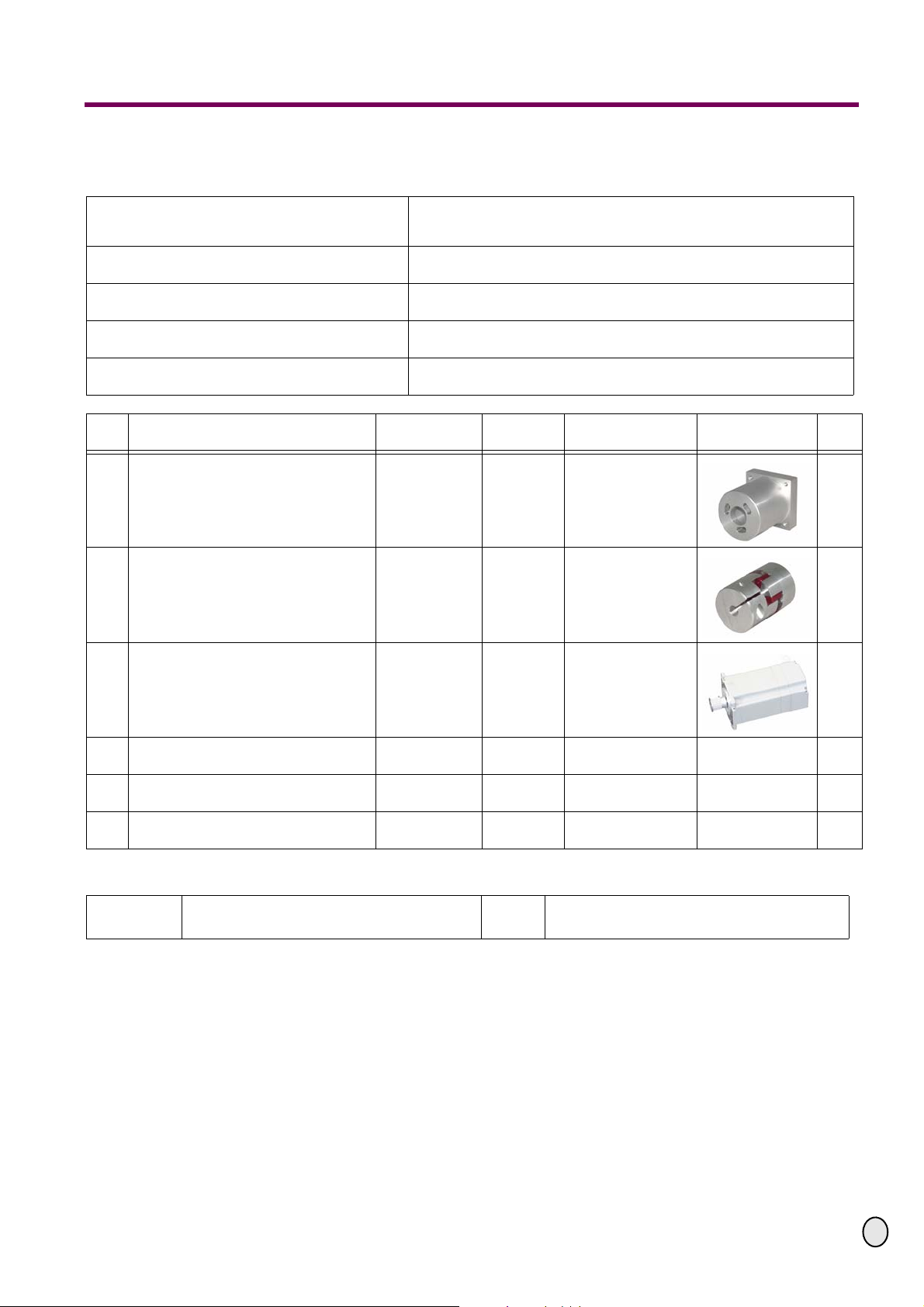

2 Packing list RT 100 CNC

Bezeichnung

Designation CNC - Adapter kit MK RT1 f

RT 100 CNC

Artikelnummer Anbausatz

Item No. assembly kit 3570510

Netto Gewicht

Net Weight 2 kg

Brutto Gewicht

Gross Weight 2.5 kg

Abmessung (Lx B x H)

Dimension (L x W x H) 320 x 285 x 80 mm

Nr.

No Bezeichnung

Description Artikelnummer

Article No. Teile Nr.

Part No. Grösse

Size Abbildung

Picture

Stck.

Qty.

1Gehäuse

Housing 0 357 0510 1 RT1CNC-01 1

2Kupplung

Clutch 0 357 0510 2 RT1CNC-02 1

3Schrittmotor

Step motor 357 3304 23H280-01EA

2,2 NM

3A 1

4Schraube

Screw DIN 4762 M5x15 4

5Schraube

Screw DIN 4762 M5x20 3

6Kabel

Cable wire -4 x 0,75mm23m

Prüfer:

Verified by: Datum:

Date:

Packing list RT 150 CNC

OPTIMUM

MASCHINEN - GERMANY

25.8.09Page 6 Packing list RT 150 CNC Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009 GB

3 Packing list RT 150 CNC

Bezeichnung

Designation CNC - Adapter kit MK RT1 f

RT 150 CNC

Artikelnummer Anbausatz

Item No. assembly kit 3570510

Netto Gewicht

Net Weight 2 kg

Brutto Gewicht

Gross Weight 2.5 kg

Abmessung (Lx B x H)

Dimension (L x W x H) 320 x 285 x 80 mm

Nr.

No Bezeichnung

Description Artikelnummer

Article No. Teile Nr.

Part No. Grösse

Size Abbildung

Picture

Stck.

Qty.

1Gehäuse

Housing 0 357 0510 1 RT1CNC-01 1

2Kupplung

Clutch 0 357 0510 2 RT1CNC-02 1

3Schrittmotor

Step motor 357 3304 23H280-01EA

2,2 NM

3A 1

4Schraube

Screw DIN 4762 M5x15 4

5Schraube

Screw DIN 4762 M5x20 3

6Kabel

Cable wire -4 x 0,75mm23m

Prüfer:

Verified by: Datum:

Date:

OPTIMUM

MASCHINEN - GERMANY

Assembly RT 100/ 150 CNC

25.8.09 Page 7Assembly RT 100/ 150 CNC Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009

GB

4 Assembly RT 100/ 150 CNC

4.1 Assembly on the RT

4.1.1 Unfasten and unscrew the hexagon

socket head screw of the handwheel

with an Allen key.

Illustr.4-1: Unscrew screws

4.1.2 Remove the handwheel from the shaft.

If you cannot pull it off easily, you can

detach the handwheel by slightly

knocking on it with a plastic tip hammer.

Illustr.4-2: Pull off handwheel

4.1.3 Take the feather key out of the shaft.

Illustr.4-3: Disassembly of feather key

Handwheel

Hexagon socket head

screw

Handwheel

Feather key

Assembly RT 100/ 150 CNC

OPTIMUM

MASCHINEN - GERMANY

25.8.09Page 8 Assembly RT 100/ 150 CNC Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009 GB

4.1.4 Stick the housing on the RT, as shown.

Illustr.4-4: Mount housing

4.1.5 Fasten the housing with the three hexa-

gon socket head screws on the RT.

Please make sure that the housing is

screwed on in a way that the motor is

horizontally positioned on the RT.

Illustr.4-5: Fasten screws

4.1.6 Shift on half of the clutch with the lar-

ger holes on the shaft of the RT, as

shown.

Illustr.4-6: Fit clutch

Housing

RT

Housing

Hexagon socket head

screws

clutch

OPTIMUM

MASCHINEN - GERMANY

Assembly RT 100/ 150 CNC

25.8.09 Page 9Assembly RT 100/ 150 CNC Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009

GB

4.1.7 Fasten the clutch through the holes of

the housing with an Allen key.

Illustr.4-7: Fasten clutch

4.1.8 Plug the other half of the clutch on the

shaft of the step motor.

Illustr.4-8: Clutch on the motor

4.1.9 The clutch should be pushed on the

shaft of the step motor as far as possi-

ble. Then fasten the clutch with an Allen

key.

Illustr.4-9: Fasten clutch

Holes of the housing

Clutch

Clutch

Step motor

Assembly RT 100/ 150 CNC

OPTIMUM

MASCHINEN - GERMANY

25.8.09Page 10 Assembly RT 100/ 150 CNC Adapter kit RT 100 /150 CNC ; Version 1.1.1

© 2009 GB

4.1.10 Align the clutch of the step motor in a

way that it fits with the counterpart in

the housing. Then put the motor on the

housing.

Illustr.4-10: Fit the step motor

4.1.11 Fasten the motor with the hexagon

socket head screws on the housing.

Illustr.4-11: Screw the motor

Step motor

Motor screw

This manual suits for next models

1

Table of contents