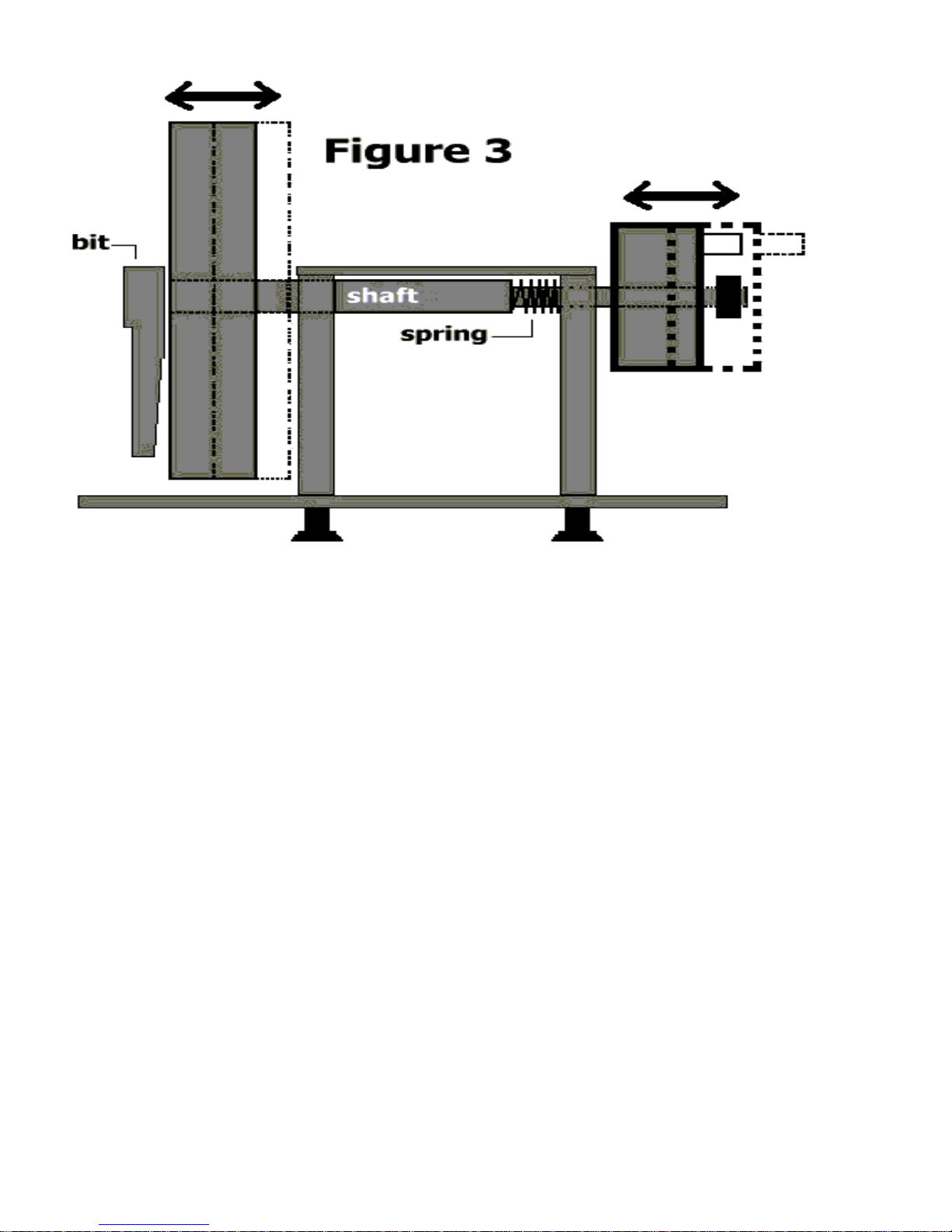

block and depress the button. Keeping the button depressed, slide the

block to its new position and then release the button. Turn the hand wheel

three or four rotations to make sure the screw drive threads are reseated.

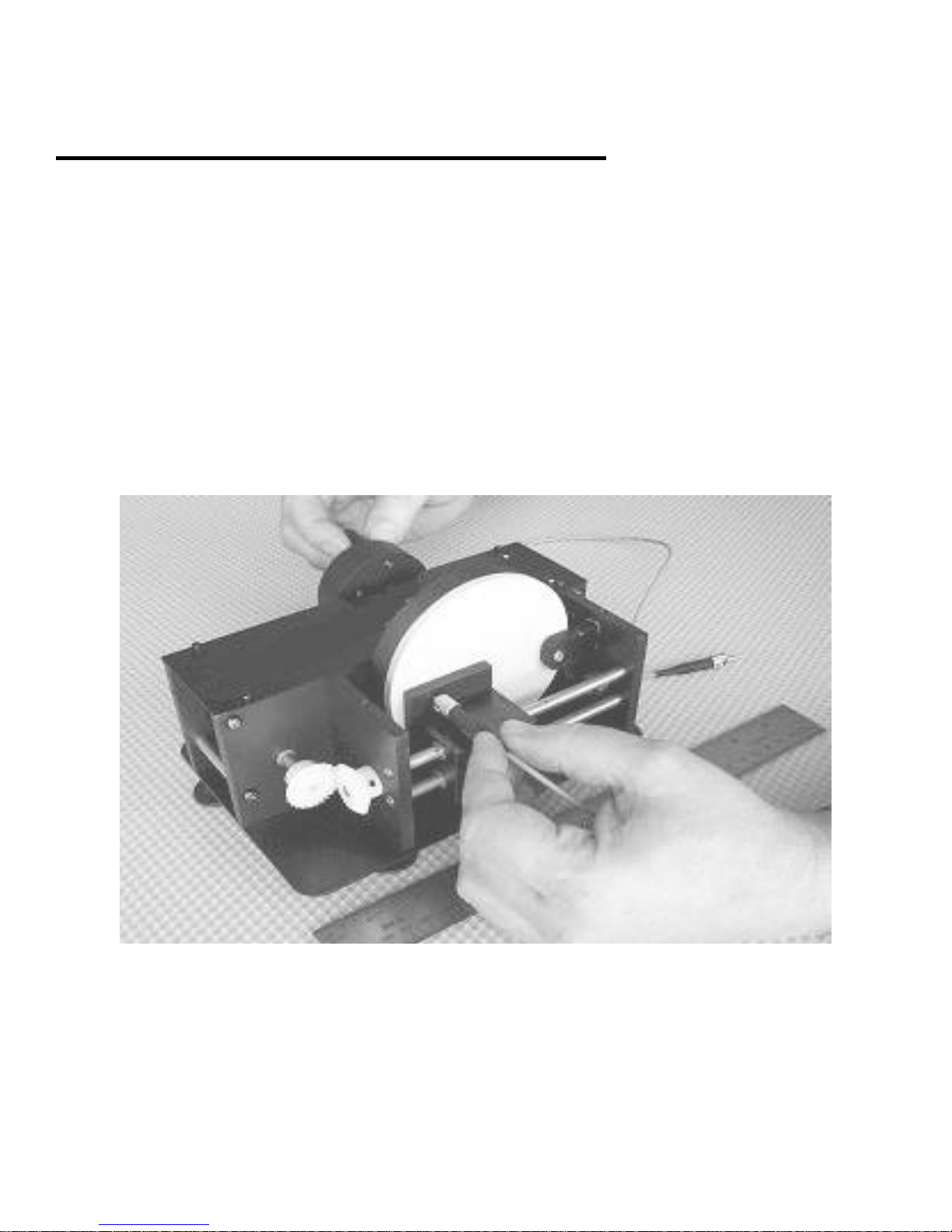

Spacing the Bit From the Polishing Disc

Maintaining proper spacing between the bit and polishing film disc is

necessary for efficient operation. Your unit's spacing should have already

been set properly at the factory. If there is no spacing, the polishing

medium will contact the surface of the bit causing unnecessary wear on

both bit and polishing medium. If the spacing is to great, there may be

insufficient contact between fiber/ferrule and polishing medium.

A simple way to adjust the

spacing between bit and

polishing disc is as follows:

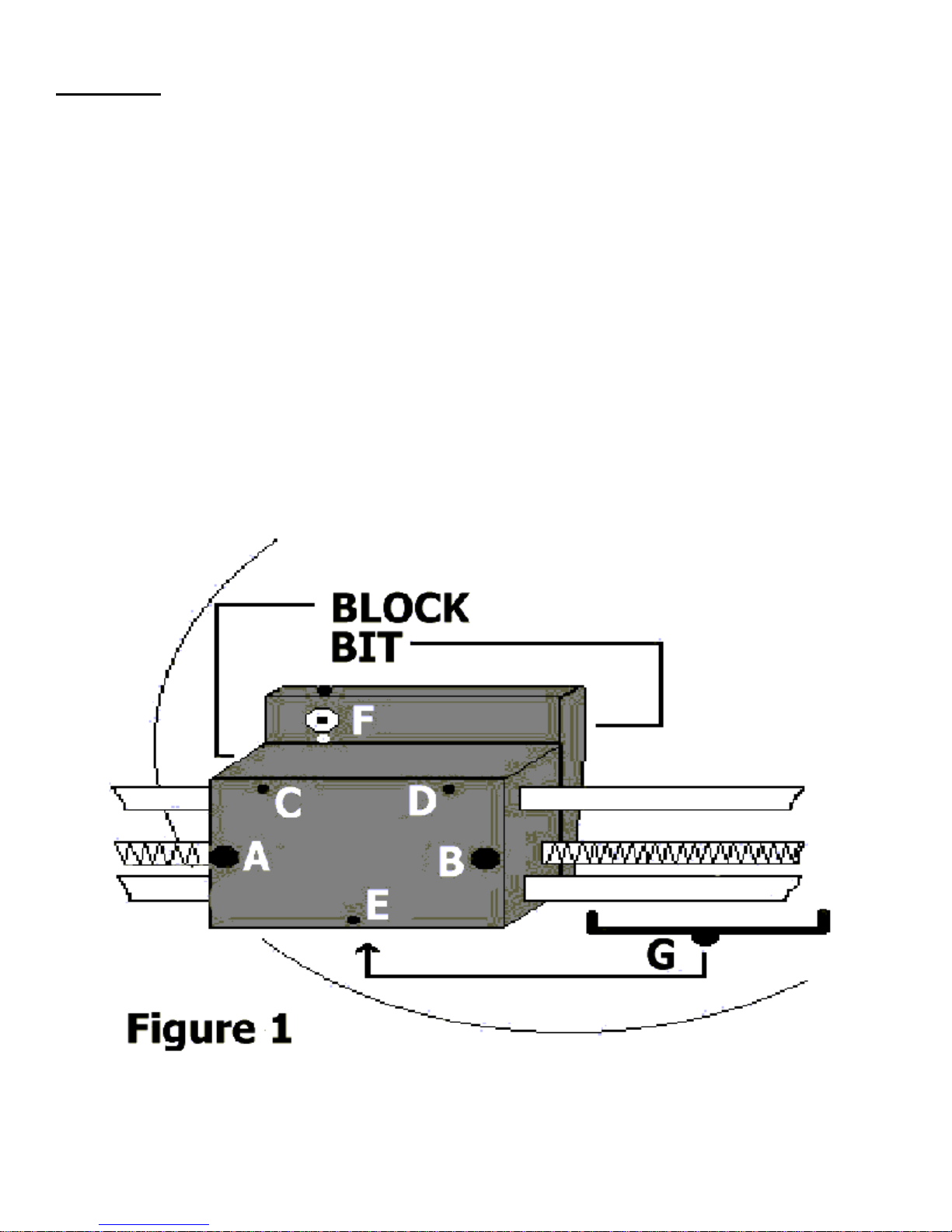

Loosen the 3/32 allen

setscrew as shown in figure

2. This setscrew prevents

the hand wheel from

spinning on the drive shaft.

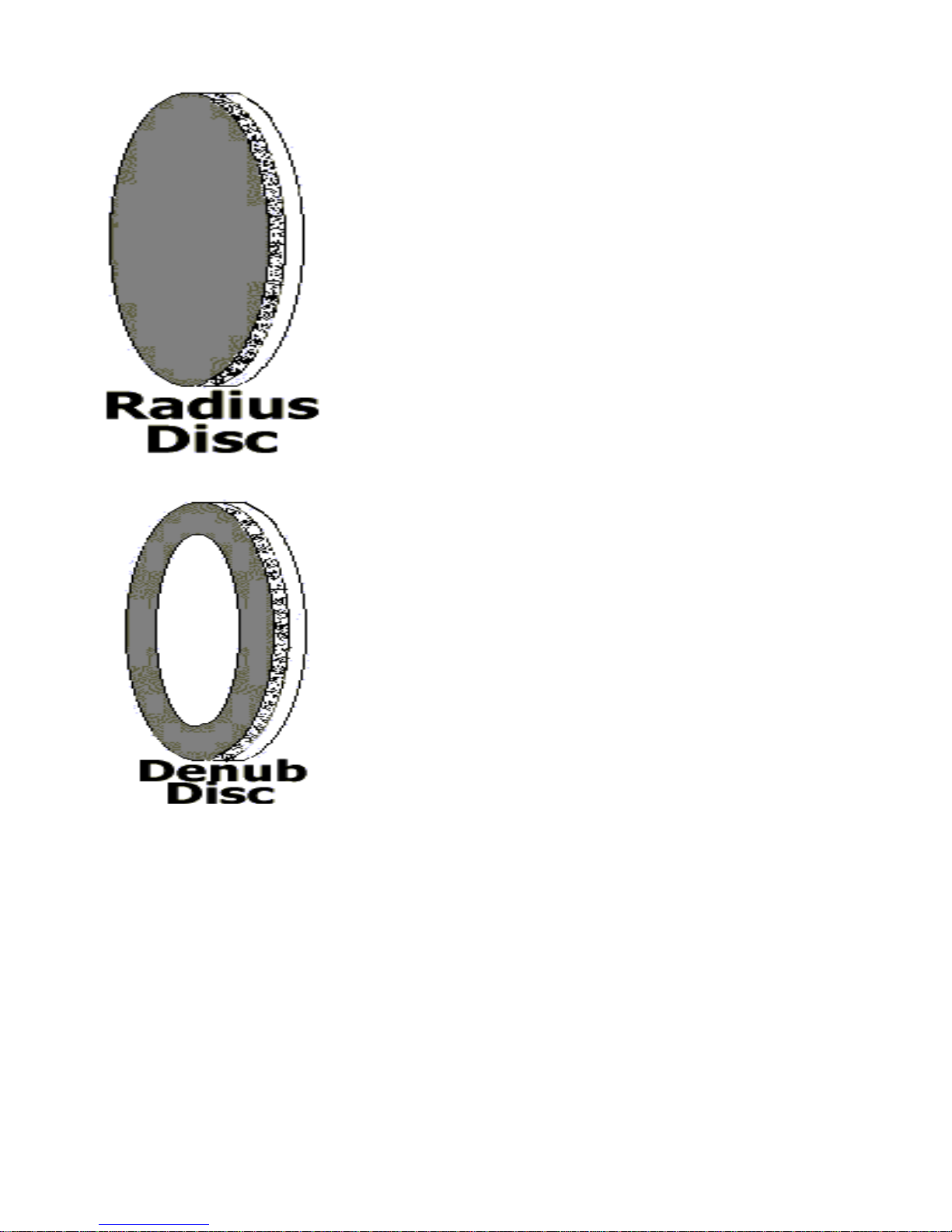

Select a solid construction

polishing disc . If you are

flat polishing primarily,

select the glass disc. If you

are polishing pre-radiused

ferrules primarily, use the

solid disc with rubber surface. Mount the selected polishing disc on the

polishing wheel with the bit of your choice previously installed and

squared. Loosen the tensioning nut until the polishing medium contacts the

bit. Pull the hand wheel back until a gap exists between bit and polishing

medium. Place an ordinary piece of typing paper between the bit and the

polishing paper and then release the hand wheel so that the paper is caught

between the bit and the polishing medium.

7