4

INDUSTRIAL 16PC ANGLE SANDER KIT INDUSTRIAL 16PC ANGLE SANDER KIT

7) Additional Safety instruction for Air Sanders

1. Hold air tool by insulated gripping surfaces, as the sanding pad may contact its own air hose. Cutting a “live” air hose may

cause hose to rupture and pose a hazard to yourself and others.

2. Disposing of dust. Be extremely careful of dust disposal, materials in fine particle form may be explosive. Do not throw sanding

dust on an open fire. Spontaneous combustion, may in time, result from a mixture of oil or water with dust particles.

3. Always wear eye protection and a dust mask for dusty applications and when sanding overhead. Sanding particles can be

absorbed by your eyes and inhaled easily and may cause health complications.

4. Use special precautions when sanding chemically pressure treated timber, paint that may be lead based, or any other

materials that may contain carcinogens. A suitable breathing respirator and protective clothing must be worn by all persons

entering the work area. Work should be sealed by plastic sheeting and persons not protected should be kept out until work area

is thoroughly cleaned.

5. Do not ‘wet sand’ with this sander. Liquids entering the motor housing will cause corrosion.

6. Do not use sandpaper intended for larger sanding pads. Larger sandpaper will extend beyond the sanding pad causing

snagging, tearing of the paper or kick-back. Extra paper extending beyond the sanding pad can also cause serious lacerations.

WARNING! Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints;

• Crystalline silica from bricks, cement and other masonry products, and;

• Arsenic and chromium from chemically-treated timber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals:

work in a well-ventilated area and work with approved safety equipment, such as dust masks that are specially designed to filter out

microscopic particles.

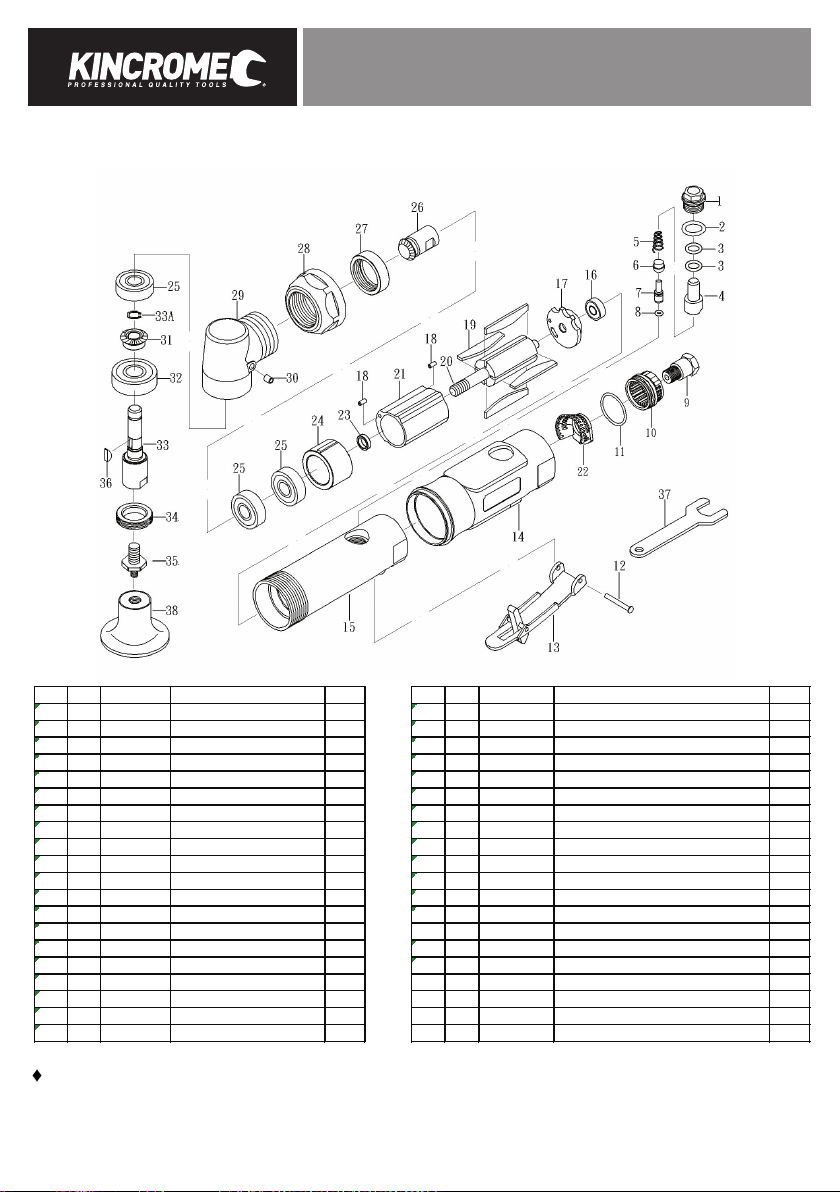

8) Assembly

Attaching/Removing a sanding pad

1. Firstly you must attach the spindle adaptor (1) to the spindle (2), by screwing it in by hand, then tighten it in using the spindle

spanners (10).

2. Once the spindle adaptor (1) has been firmly attached, then select either the 50mm backing pad (11) or the 75mm backing pad

(12). Once you have selected which pad would be most suitable for the job, then line up the threads and screw in tightly using

your hands.

3. Once you have chosen the suitable backing pad (11 or 12) then select the appropriate sanding disc (13-18), and screw in by hand

to the face of the backing pad (do not over tighten).

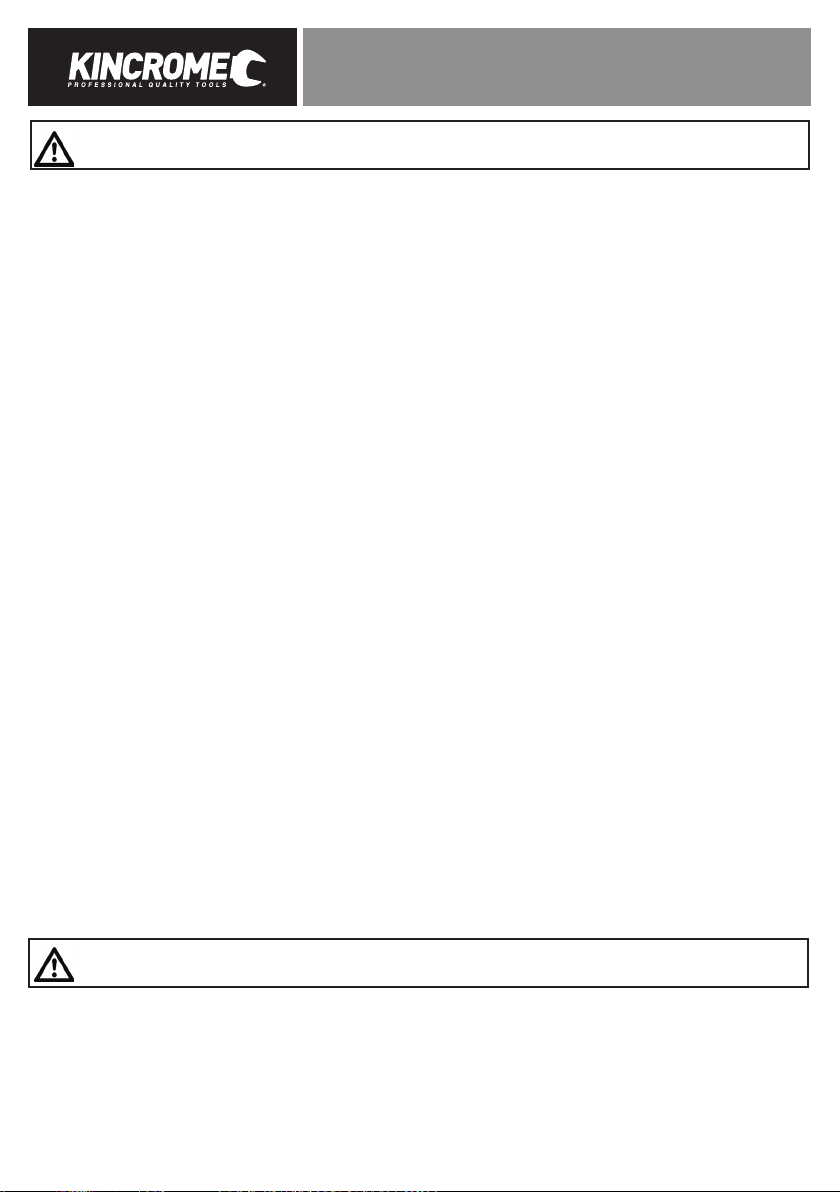

9) Before Starting

TO PREVENT SERIOUS INJURY FROM EXPLOSION:

Verify compressor is off before setup. Use only clean, dry, regulated,

compressed air to power this tool. Do not use oxygen, carbon dioxide,

combustible gases, or any other bottled gas as a power source for this

tool.

1. It is recommended a filter, regulator with pressure gauge, oiler,

in-line shut-off valve, and quick coupler be fitted for optimal

operation, as shown on Figure A.

2. An in-line shut-off ball valve is an important safety device,

it will shut-off the air supply even if the air hose is ruptured.

The shut-off valve should be a ball valve because it can be

closed quickly.

Note: If an automatic oiler system is not used, add a 4 to 5 drops of

Kincrome Air Tool Oil to the air inlet (7) before operation. Add 1-2

more drops every hour of continual use.

3. Attach an air hose to the compressor’s air outlet. Connect the air hose to the air inlet (7) of the tool. Other components, such as

a quick connect fitting and quick connect coupler, will make operation more efficient, but are not required.

Figure A