Optoma GT750 User manual

Other Optoma Projector manuals

Optoma

Optoma X400LV User manual

Optoma

Optoma HD81-LV User manual

Optoma

Optoma MovieTime DV11 User manual

Optoma

Optoma EH300 User manual

Optoma

Optoma HD6720 User manual

Optoma

Optoma HD36 User manual

Optoma

Optoma Optoma EP728 User manual

Optoma

Optoma ThemeScene HD65 User manual

Optoma

Optoma EzPro 732E User manual

Optoma

Optoma HD67 User manual

Optoma

Optoma HD8300 User manual

Optoma

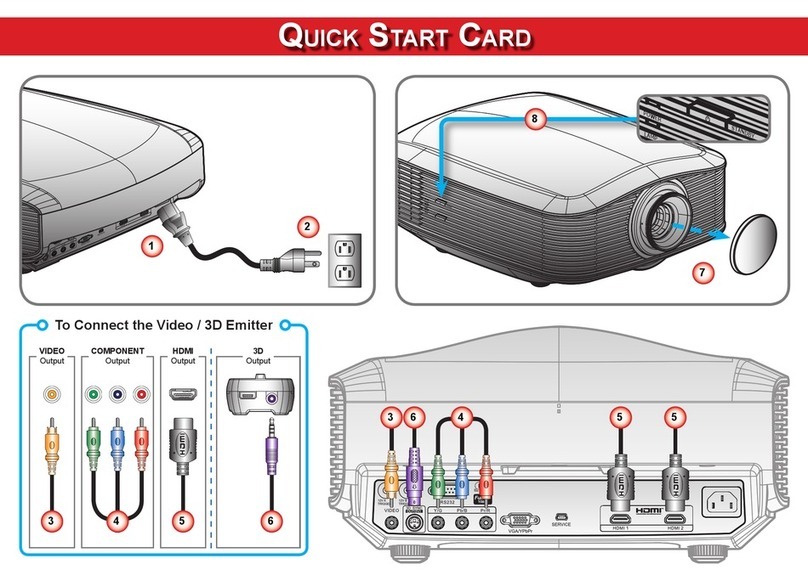

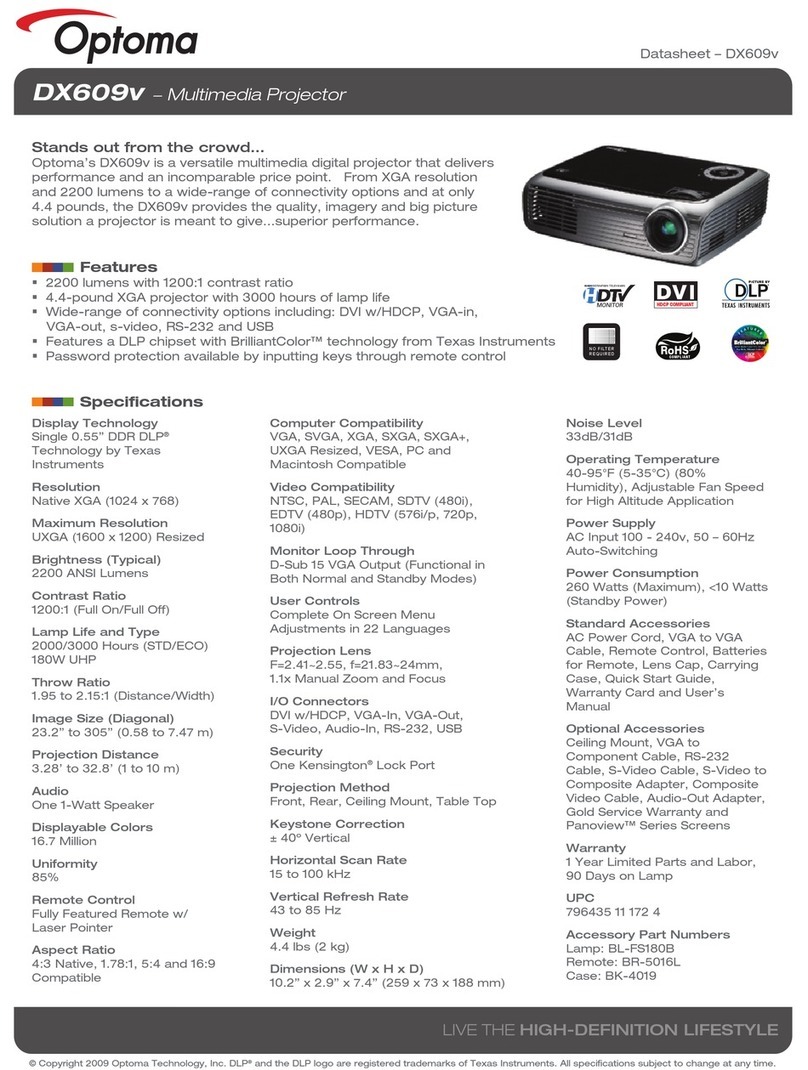

Optoma DX609v User manual

Optoma

Optoma TH1060 User manual

Optoma

Optoma TX779 Technical manual

Optoma

Optoma Theme Scene HD82 Instruction manual

Optoma

Optoma ML750ST-M User manual

Optoma

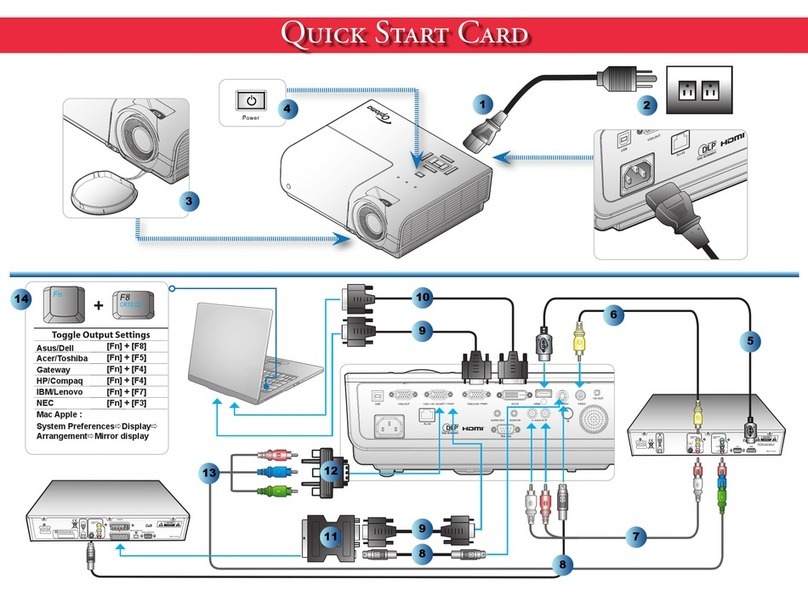

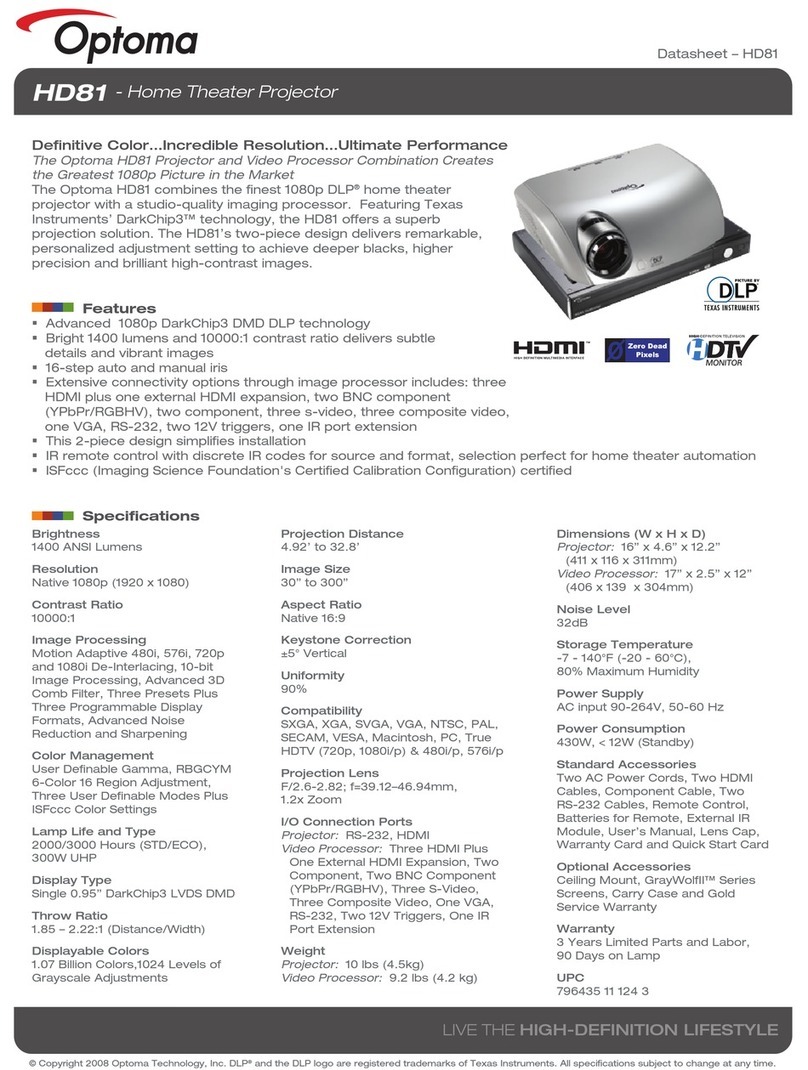

Optoma HD81 User manual

Optoma

Optoma ES526 User manual

Optoma

Optoma UHZ4000 User manual

Optoma

Optoma Pico PK201 User manual