OMX 333UNI

SETTING PROFI

OMX 333UNI

CONNECTION AND CONTROLLING OF INSTRUMENT / TECHNICAL DATA

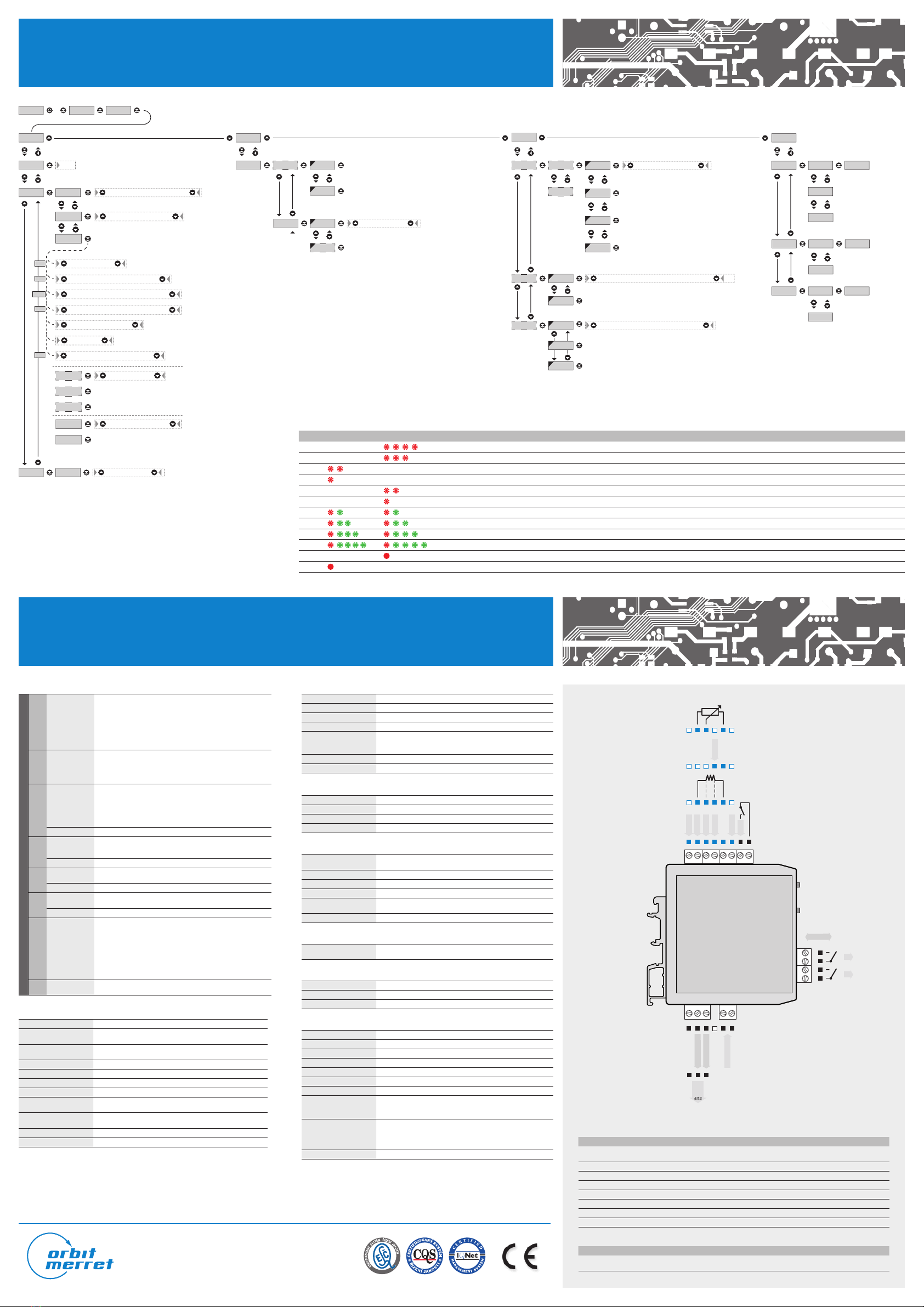

142. 8 +PAS . 0

INP.CHA .SER.

OUT.

LI M . L. 1 RES .

SAV.

CLR.C. TA.

CFG .

C. A. MI N . 1

FI L .MOD.

CO N . 0

NO EXP.. RND.

MAX. 1

N.PA.

FI R .

USR.

YES

P. PR.

P. LI . 0

Zeroing of tare

Setting of measuring rate

Setting of instrument’s measuring mode

Setting for beginning of range

Setting the filtration constant

Setting the digital filters*

Setting for end of range

EXT. EX .1 OFF HLD. TAR..

Selection of auxiliary input function

Setting of baud rate

T.1 0

H.1 0

L.1 25

TYP.CLO. OPE. rDY. Err.

Setting of limit’s time delay

Setting of limit’s hysteresis

Setting of limit value

Selecting output mode**

Setting access passwords

Restoring manufacturer’s settings

CAL.

C.HI .

C.LO . 0

Calibratin of the range (DU)

M.P.S. 0.5 1.2 2.5 5.0 10.0 20.0

DC

PM

RTD

MOD

TYP DC PM T/C DU

I 0. I 4. E4. U 2. U 5. U10.

E0.1 E0.5 E1.0 U0.1 r.0.5 r0.1

T/C BEJ KN R S t L

30n 60m U.1

CO N .

R.AD . 0

LEA .

T. C.J . 0

2-u 3-u 4-u

CO N .IN.1 IN.2 EX.1 EX.2

0

Cu.1 Cu..2 Cu.3 Cu.4

Ni.5 Ni.6

E0.1 E0.5 E1.0 U0.1 r.0.5 r0.1

OHM

Selection of input and range

Setting for RTD

Setting for T/C

SET.

ADD. 0

DAT.DAUB 600 1200 2400 115200 230400

100A.Hi

0A.Lo

A. O. TYP.AV.i 20 E. 4. i 4. i 5. u 2 u 5 u10

Setting of address

Setting maximum for analogue output

Selecting output type

Setting minimum for analogue output

L. 2

ERROR MESSAGES

ERROR LED “LO” LED “HI” CAUSE SOLUTION

E.D. U . number is too low (or high negative) to be displayed (less than -99999) change setting of channel constant

E.D. O . number is too high to be displayed (greater than 99999) change setting of channel constant

E.T. U . number is out of table range (lower) widen values in table (add first line), change input setting (channel constants)

E.T. O . number is out of table range (greater) widen values in table (add last line), change input setting (channel constants)

E.I . U. input value is lower than permitted input range change value of input signal or change settings of input range

E.I . O. input value is greater than permitted input range change value of input signal or change settings of input range

E.HW.a part of the instrument is not functioning properly send to manufacturer to be serviced

E.E. E. data in EEPROM corrupted restore manufacturer’s settings, if error message reoccures, send to manufacturer to be serviced

E.D. T. data in EEPROM out of range restore manufacturer’s settings, if error message reoccures, send to manufacturer to be serviced

E.CL.memory was empty (pre-setting had taken place) if error message reoccures, send to manufacturer to be serviced, possibilty of corrupted calibration data

E.IN.input leads disconnected check leads and their connection

E.OU.output leads disconnected check leads and their connection

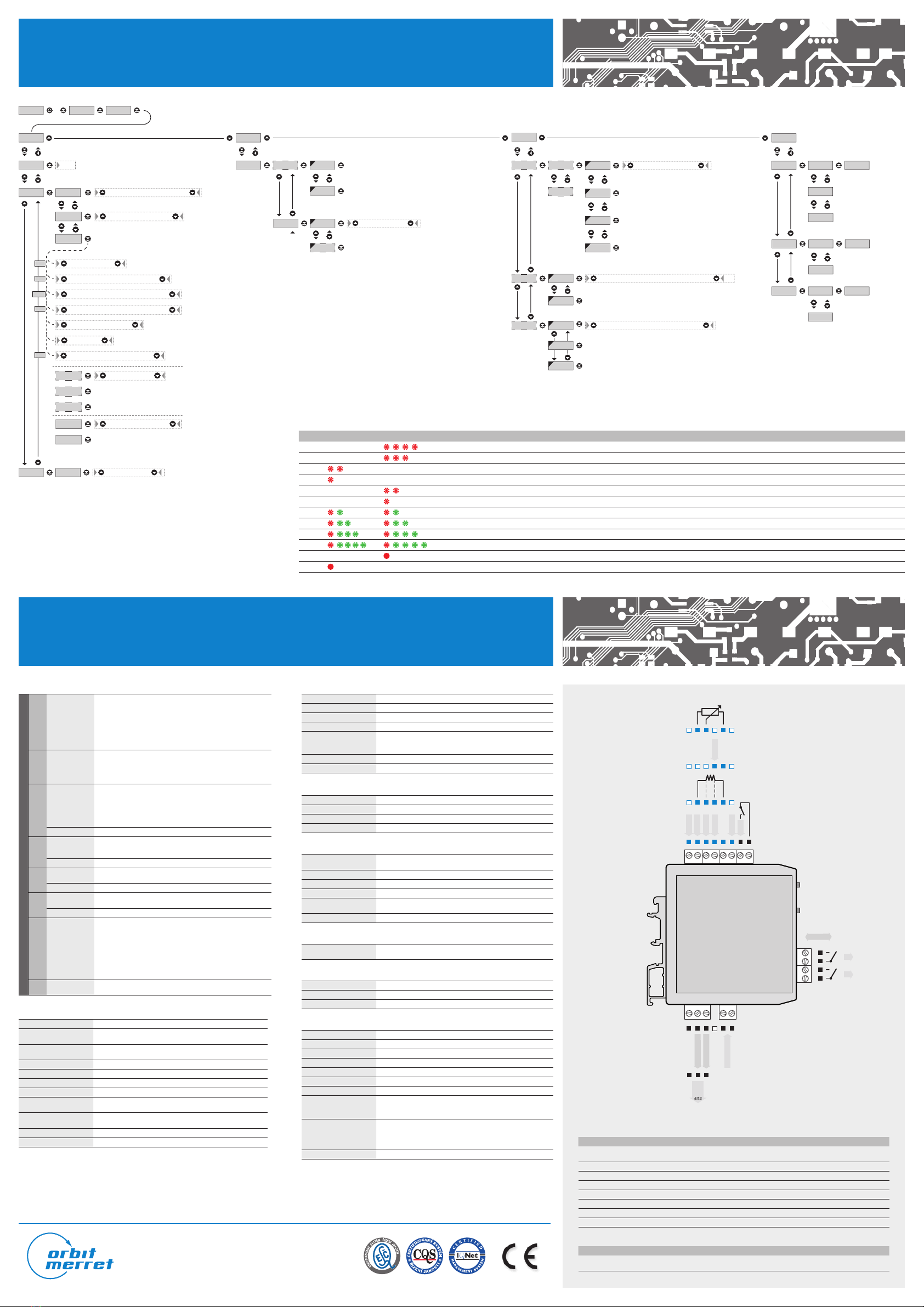

S+ S-E+ E-

ES-

E-

ES+

ES+

DC, PM

RTD, OHM, Ni

DU

T/C

S-

L2

L1

OM Link

123 45

1234

JKLMNONO

AO - current

AO - voltage

GND

Power supply

+

+

+

--

Rx/Tx-

Termination

Rx/Tx+

485

-

+

EXT.1

GND

+

+

INPUT 1

+

-

+

+

INPUT 2

INPUT 3

INPUT 4

INPUT 5

GND

+

-

INPUT 4

-

+

MEASURING RANGES - CONNECTION

TYPE INPUTS 1 INPUTS 2 INPUTS 3 INPUTS 4 INPUTS 5

DC ±20/±40/±80 V ±30/60 mV

±1 V ±80/±180 mA

PM ±2/±5/±10 V 0/4…20 mA

OHM 0…300 Ω/0…1,5 kΩ/0…3 kΩ/0…30 kΩ

RTD-PT Pt 100/Pt 500/Pt 1 000

RTD-CU Cu 50/Cu 100

RTD-NI Ni 1 000/Ni 10 000

T/C J/K/T/E/B/S/ R/N/L

DU Linear potentiometr (min. 500 Ω)

EXTERNAL INPUT

DESCRIPTION ACTION

EXT. 1 control input, functionality according to

setting in the menu (see Menu > EXT.1) upon contact, terminal (no. N + O)

Instrument‘s power supply leads should not be in vicinity of low level input signals. Contactors, medium and high power electrical motors must not be used in vicinity of the instrument.

Input signal leads (measured value) need to be separated from all high power leads and devices. Instruments are tested in accordance with standards for industrial use, however we

strongly advise you to adhere to the above mentioned precaution measures.

In order to ensure proper functionality of this instrument it is absolutely essential to connect the input leads shielding to the junction box‘ frame.

MEASURING INPUT

INPUT

DC Ranges

±80 mA < 1 V Input 5

±180 mA < 2 V Input 5

±30 mV > 10 MΩ Input 4

±60 mV > 10 MΩ Input 4

±1 V > 10 MΩ Input 4

±20 V 1 MΩ Input 1

±40 V 1 MΩ Input 1

±80 V 1 MΩ Input 1

PM Ranges

±20 mA < 200 mV Input 5

4...20 mA < 200 mV Input 5

±2 V > 10 MΩ Input 1

±5 V 1 MΩ Input 1

±10 V 1 MΩ Input 1

OHM Ranges

0…100 Ω

0...300 Ω

0...1,5 kΩ

0...3 kΩ

0…24 kΩ

0...30 kΩ (only for 2- or 4-wire)

Connection 2-, 3- or 4-wire

RTD Type

EU > 100/500/1000 Ω, w.3 850 ppm -50°…450°C

US > 100 Ω, with 3 920 ppm/°C -50°…450°C

RU > 50/100 Ω with 3 910 ppm/°C -200°…1 100°/450°C

Connection 2-, 3- or 4-wire

Ni Type Ni 1000/ Ni 10000 w.5 000 ppm/°C -50°…250°C

Ni 1000/ Ni 10000 w.6 180 ppm/°C -200°…250°C

Connection 2-, 3- or 4-wire

Cu Type Cu 50/Cu 100 with 4 260 ppm/°C -50°…200°C

Cu 50/Cu 100 with 4 280 ppm/°C -200°…200°C

Connection 2-, 3- or 4-wire

T/C Type

J (Fe-CuNi) -200°...900°C

K(NiCr-Ni) -200°...1 300°C

T (Cu-CuNi) -200°...400°C

E (NiCr-CuNi) -200°...690°C

B (PtRh30-PtRh6) 300°...1 820°C

S(PtRh10-Pt) -50°...1 760°C

R (Pt13Rh-Pt) -50°...1 740°C

N (Omegalloy) -200°...1 300°C

L (Fe-CuNi) -200°...900°C

DU Supply of linear

potentiometer 2,5 VDC/6 mA, min. resistance of potentiometer is 500 Ω

INSTRUMENT’S ACCURACY

TK 50 ppm/°C

Accuracy ±0,05 % of the range + 1 digit

±0,05 % of the range + 1 digit

Accuracy of cold

junction measurement ±1,5°C

Rate 0,5…80 measurements/s

Overload capacity 10x (t < 30 ms), 2x

Digital filtres exponencialn filter, rounding

Function Hold - “freezing the measured value”, Tare (upon contact)

External input 1, with the possibility of assigning various functions in

the instrument’s menu

OM Link Company communication interface for operating,

setting and updating of instruments

Watch-dog reset after 500 ms

Calibration at 25°C and40% r.h.

COMPARATOR

Type digital, setting in vmenu

Limits 0…999999

Hysteresis 0…999999

Delay 0…99,9 s

Outputs

up to 2x relays with switch-on contact (Form A),

(250 VAC/30 VDC, 3 A)*

2x open collector, (30 VDC/100 mA)*

Reaction speed < 50 ms

Relay 1/8 HP 277 VAC, 1/10 HP 125 V, Pilot Duty D300

* values apply to resistive load

DATA OUTPUT

Protocol ASCII

Data format 8 bit + no parity + 1 stop bit

Rate 600…230 400 Baud

RS 485 isolated, adressing (max. 31 instruments)

ANALOG OUTPUT

Type isolated, programmable with 12-bit D/A converter,

type and range are selectable in menu

Non-linearity 0,1 % of range

TK 15 ppm/°C

Rate response to change of value < 1 ms

Output 0…2/5/10 V, ±10 V, 0…5 mA, 0/4…20 mA

(comp. < 500 Ω/12 V), Detection of broken loop

Ripple 5 mV residual ripple at output voltage of 10 V

POWER SUPPLY

10…30 VDC/24 VAC, ±10 %, 3 VA, PF ≥ 0,4,

ISTP< 40 A/1 ms, isolated

MECHANIC PROPERTIES

Material PA 66, incombustible UL 94 V-0, blue

Dimensions 90,5 x 79 x 25 mm

Installation to DIN rail, wide 35 mm

OPERATING CONDITIONS

Connection connector terminal board, cross section < 1,5/2,5 mm2

Stabilization period within 15 minutes after switch-on

Working temperature -20°…60°C

Storage temperature -20°…85°C

Cover IP20

Execution safety class I

El. safety EN 61010-1, A2

Dielectric strength

2,5 kVAC after 1 min between supply/input

2,5 kVAC after 1 min between supply/outputs

4 kVAC after 1 min between input/relays output

Insulation resistance*

for pollution degree II, measuring cat. III.

power supply > 300 V (PI), 255 V (DI)

input/output > 300 V (PI)

input/output - relay > 300 V (DI)

EMC EN 61326-1 (Industrial environment)

* PI - Primary insulation, DI - Double insulation

ORBIT MERRET, spol. s r. o.

Vodňanská 675/30, 198 00 Prague 9, Czech republic

tel.: +420 281 040 200, fax.: +420 281 040 299

*Setting the digital filters

OFF filters are off

EXP. exponential filter

rnd. rouding

COn. setting of the calibration constant

**Selecting output mode

CLO. closing relay (normally open)

OPE. opening relay (normally closed)

rnY. all OK

Err. error indication

MINI-TECHDOK - OMX 333UNI - 2012 - 1v1 - en