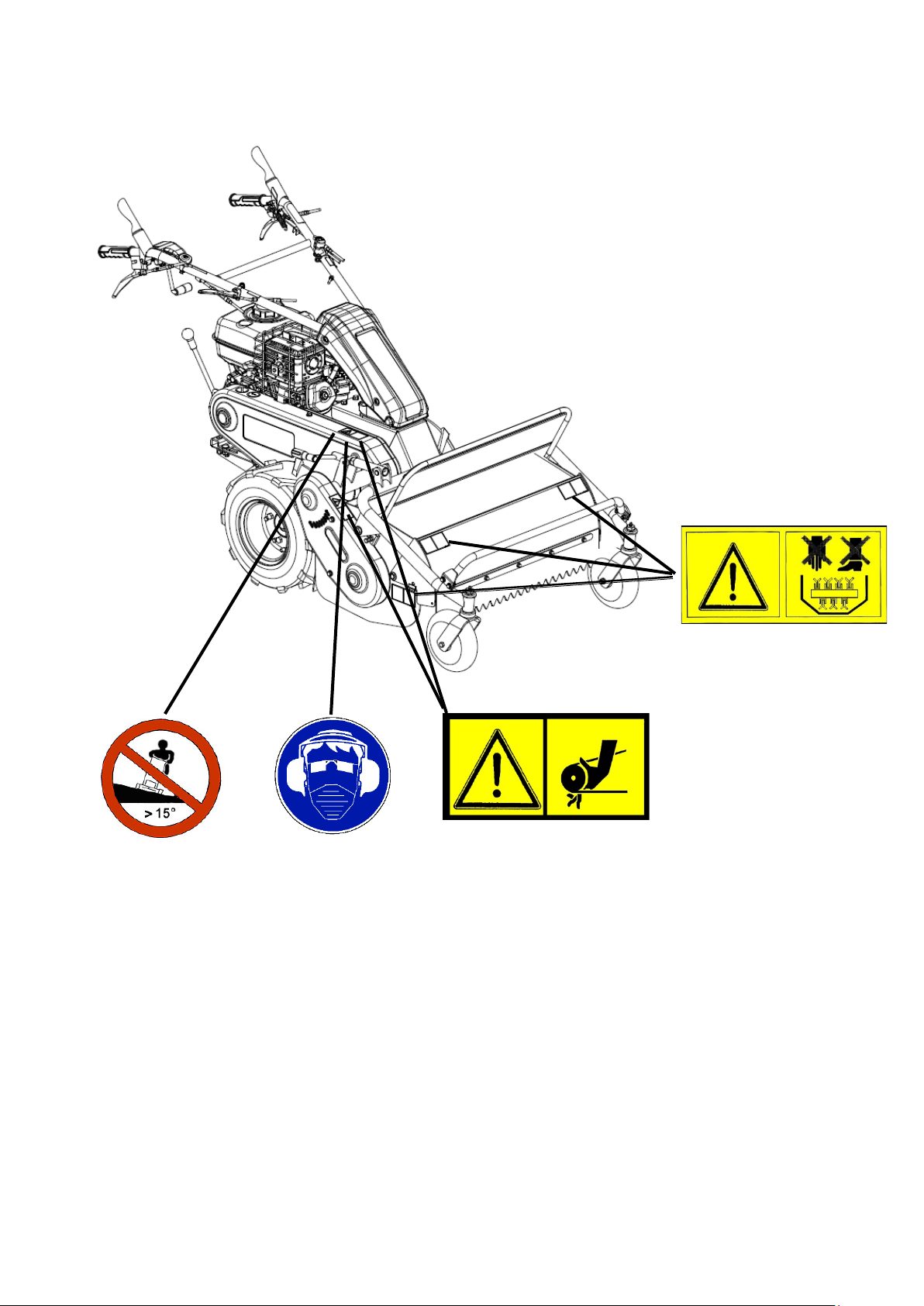

•Never stop or start roughly when working on a slope. Never use the machine to work on a stepping

terrain.

•Reduce the ground speed when running on a slope and when turning

straight in order to prevent from any risk of losing control.

•Be very careful when bordering ditches.

•Stop the engine, and remove the sparking plug ignition cover before any

intervention on the machine.

•Never work under the machine or its parts when lifted, unless they are

blocked and maintained into position with sufficient security.

•When running on a slope, always work going up or down but never across

the slope.

•Steer clear of unsteady embankments, holes or rocks. They might be dangerous during manœuvres

or transport.

•Keep away from electric wires and obstacles. A contact with electric wires cause electrocution and

death.

•Stop the machine progressively when lifting or lowering the machine.

•When stopping the work, stop the engine and remove the sparking plug ignition cover before leaving

the mower.

•Engage all the safety equipments.

•Move the controls only when correctly sat down in the mower

•Visually check hydraulic leaks and if some parts are faulty or missing. Repair before use.

•Never change the adjusment of the regulator, it is set in the factory. Unsetting this valve would cause

failures.

•Ensure that the user of the machine has already read and understood this

manual and that he is aware of all the safety instructions before any use.

•Always use a chuck and bronze hammer when replacing or intervening

on the pins and bolts at the end of rams, rod … etc in order to avoid the

projection of metal fragments.

•Clear the mowing path from foreign objects, stones, woods, cans, bottle,

pieces of steel, wich can ne thrown by the mower.

•Gasoline is hightly flammable :

•- Refuel outside, never smoke when refuelling

•- Never refuel when the engine is running, stop the engine before refuelling

•- Allowed the engine to cool down before refuelling

•- If gasoline has spilled, do not try to start engine before the spilled gasoline has been wiped.

•- Check that the fuel cap is correrctly installed after refuelling