OREC RM83G - © SAT 03/2015

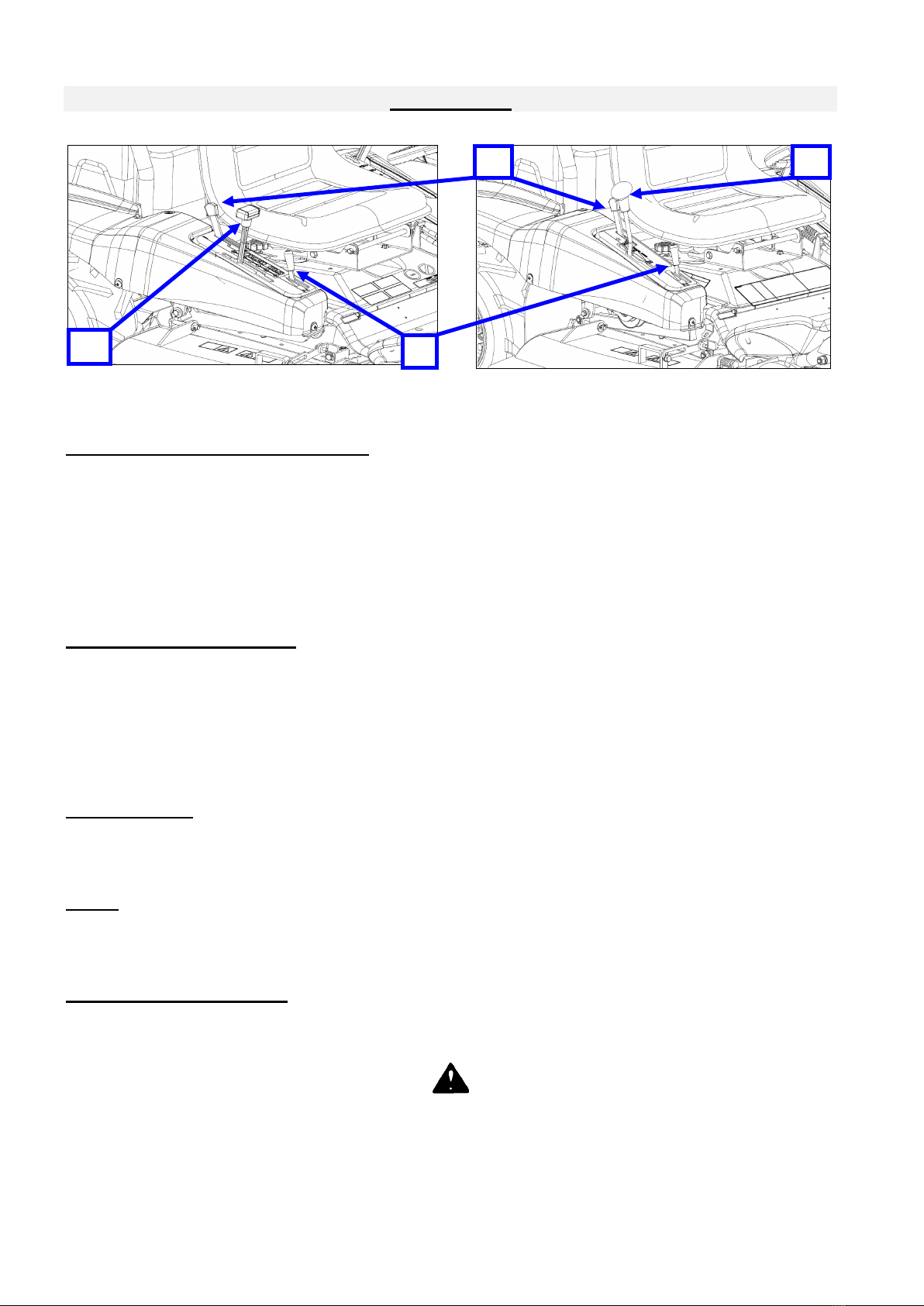

BRAKE PEDAL &LOCKING LEVER

Brake pedal is used in case of emergency or when parking brake

is locked (1,2, Figure 6).

To lock parking brake, press brake pedal, then push locking lever

(2) to the right. Depress the pedal, and after, the lever. To unlock

parking brake, press and depress brake pedal.]

(RM83G only)

Press the brake pedal (1, Figure 6) each time to change the

speed. When the brake pedal is pressed, brake works to stop

machine.

For your safety, always press the brake pedal first, then change

the speed lever position after the machine is stopped.

(RM830 only)

In the normal operation, use speed lever to stop the machine at

N position.

In case of emergency, press the brake pedal (1, Figure 6) to stop

machine, then speed lever returns to N position.

WARNING

Always inspect the brake before each use. If the brake is not properly adjusted, it may lead to

serious accident such as collision or fall. Press the brake pedal, then brake works to stop ma-

chine. When the brake pedal is pressed, it is possible to use locking lever (2, Figure 6) to lock

the parking brake. When brake pedal is further pressed, parking brake is unlocked. Engine

cannot be started when brake pedal is not pressed(locked).

WARNING

When leaving the machine be sure parking brake is locked, cutting blades are in off position

and ignition key is removed.

IGNITION KEY

Ignition key (3, Figure 6) is used to start and stop the engine.

When the key is in "stop", position the engine is stopped, the key can be removed. Turn the key

in this position when you want to stop the engine.

When the key is in "operation", position the engine can run, the key cannot be romoved in this

position

When the key is in "start", position the electric starting motor is engaged. When the engine has

started, release the key wich return in "operation", position.

STEERING WHEEL

The steering wheel(4, Figure 6) is used to allow the direction of the machine. Turn the steering wheel

to the right (clock wise) to go right and to the left to go to the left (anti-clockwise) Adjust the steering

wheel height (3 positions) by removing the pin (5, Figure 6). Adjust the steering wheel, and secure the

pin (5, Figure 6).

CAUTION

Always remove the key when machine is not used. When the engine is stopped, check than

the key is on "stop" position. Do not engage the electric starting motor more than 10 seconds.

If the engine has not start after 10 seconds, wait for 30 seconds before engage the electric

starting motor again.

WARNING

Use brake pedal in case of emergency only or to lock parking brake. If brake pedal is used at

high speed, the machine will stop suddenly.