CONTENTS

INTRODUCTION ................................................................................................................................................2

CONTENTS........................................................................................................................................................3

SPECIFICATIONS..............................................................................................................................................3

CHECK LIST.......................................................................................................................................................4

SAFETY RULES.................................................................................................................................................4

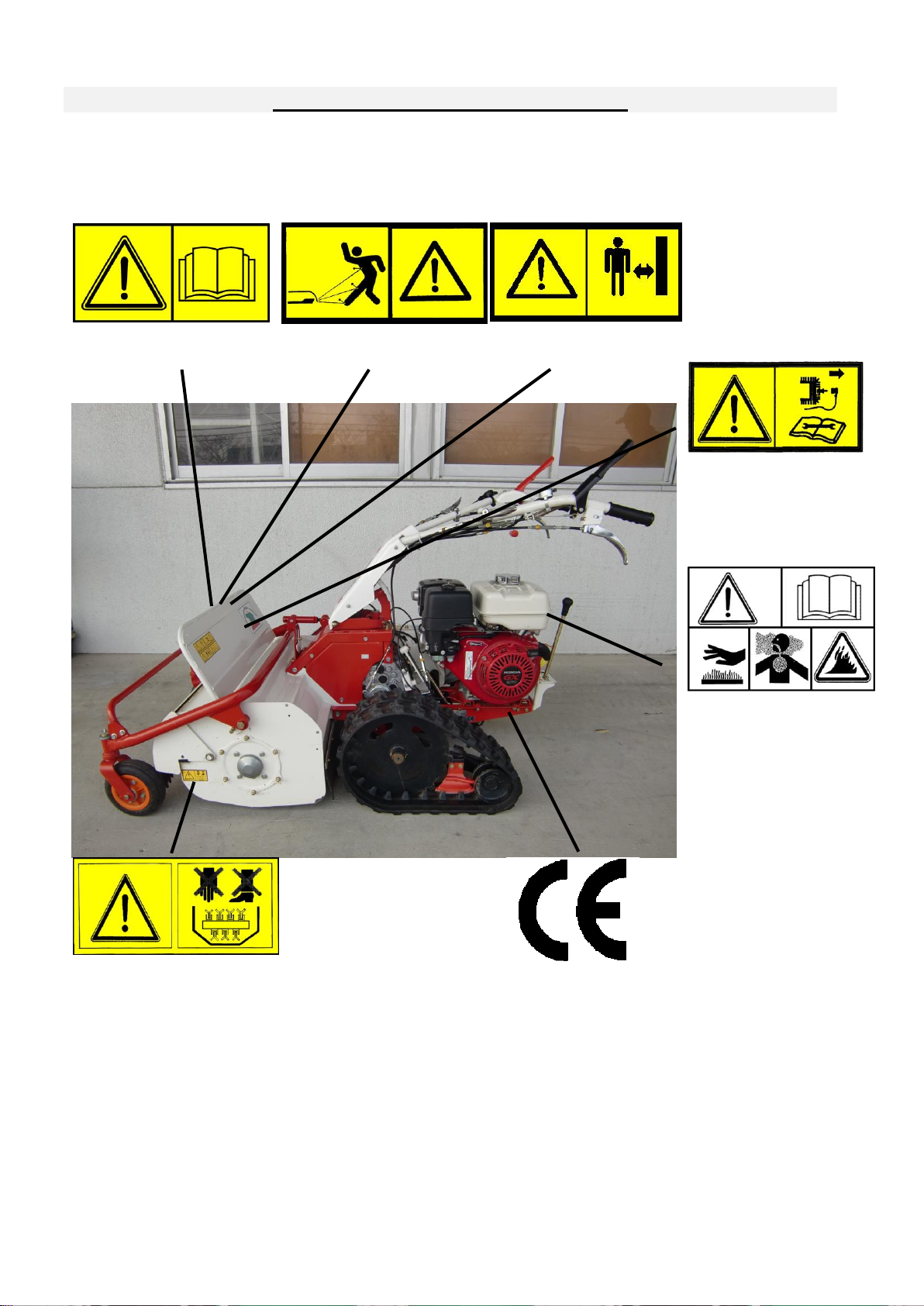

DIFFERENT PARTS OF THE MOWER.............................................................................................................6

SAFETY INSTRUCTION STICKERS .................................................................................................................7

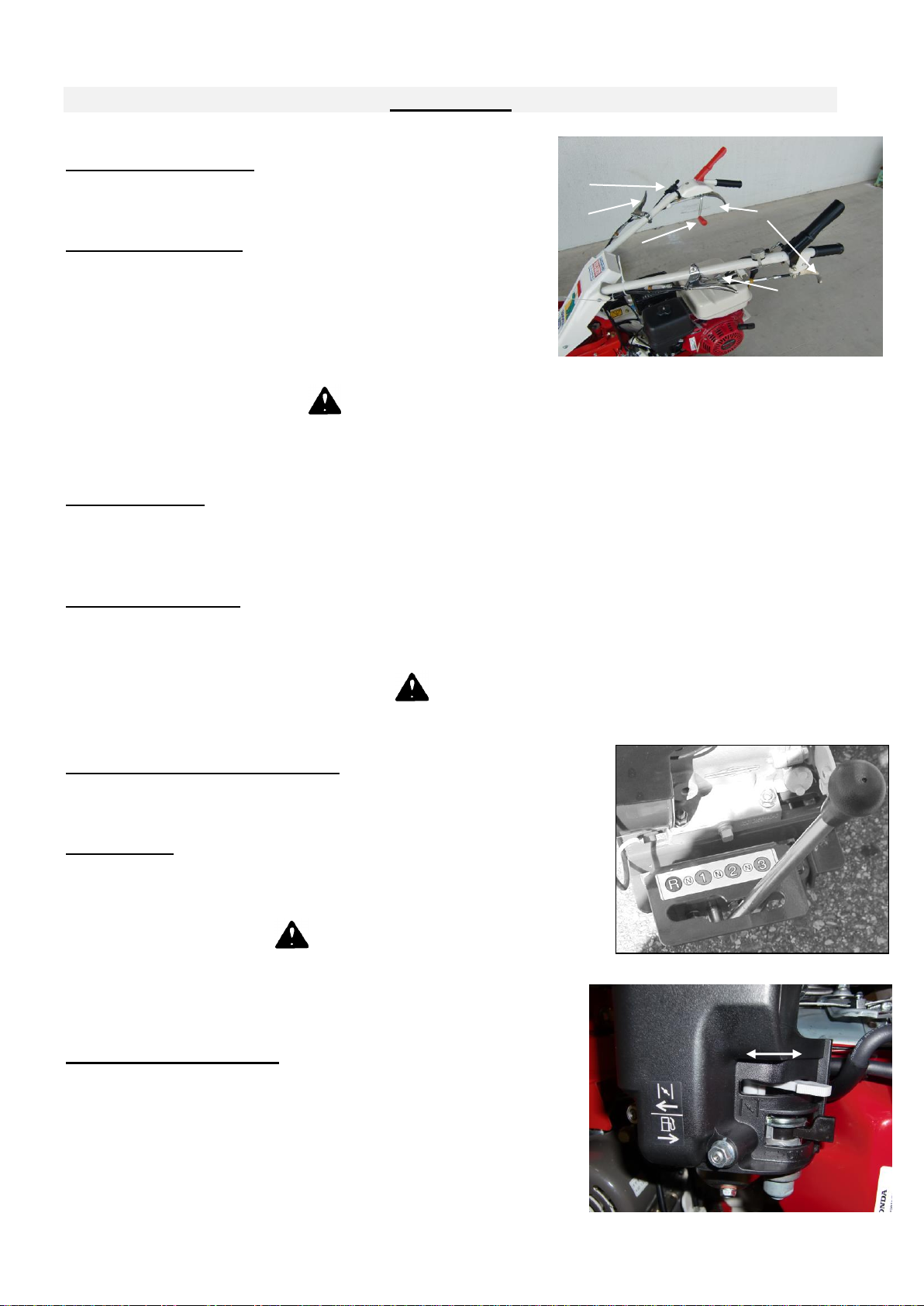

CONTROLS........................................................................................................................................................9

OPERATION.....................................................................................................................................................11

MAINTENANCE OPERATIONS TO BE CARRIED OUT BY THE USER ........................................................13

BREAKDOWNS AND SOLUTIONS .................................................................................................................20

TIGHTENING TORQUES (Nm)........................................................................................................................20

EC CONFORMITY DECLARATION.................................................................................................................21

MEASUREMENT OF VIBRATIONS.................................................................................................................21

EC CONFORMITY DECLARATION.................................................................................................................22

MEASUREMENT OF VIBRATIONS.................................................................................................................22

EC CONFORMITY DECLARATION.................................................................................................................23

MEASUREMENT OF VIBRATIONS.................................................................................................................23

EC CONFORMITY DECLARATION.................................................................................................................24

MEASUREMENT OF VIBRATIONS.................................................................................................................24

EC CONFORMITY DECLARATION.................................................................................................................25

MEASUREMENT OF VIBRATIONS.................................................................................................................25

EC CONFORMITY DECLARATION.................................................................................................................26

MEASUREMENT OF VIBRATIONS.................................................................................................................26

EC CONFORMITY DECLARATION.................................................................................................................27

MEASUREMENT OF VIBRATIONS.................................................................................................................27

EC CONFORMITY DECLARATION.................................................................................................................28

MEASUREMENT OF VIBRATIONS.................................................................................................................28

LIMITED WARRANTY......................................................................................................................................29

NOTES..............................................................................................................................................................29

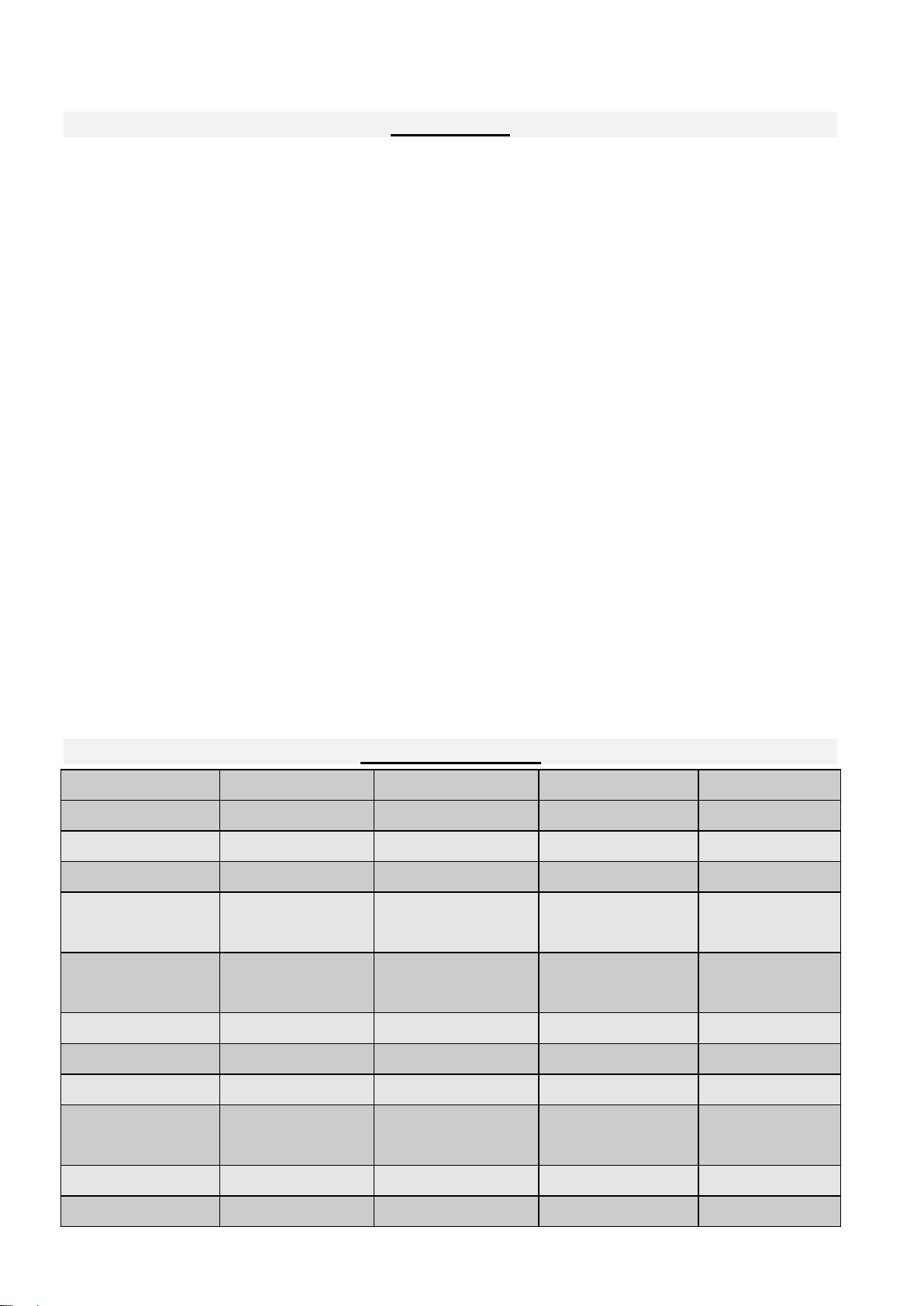

SPECIFICATIONS

(1) 0.94

(2) 1.96

(3) 3.45

(1) 0.90

(2) 1.88

(3) 3.31

(1) 0.94

(2) 1.96

(3) 3.45

(1) 0.90

(2) 1.88

(3) 3.32

Fuel tank capacity

(liters)

HRC662 / 5.3

HRC672 / 4.1

HRC802 / 6.1

HRC812 / 5.3