SAFE AND PROPER USE OF THIS MACHINE

Make sure that this manual is read and understood by the operator. Only trained operators

should operate this machine once they are familiar with the adjustments and correct method. When

using this machine, basic safety precautions should always be observed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

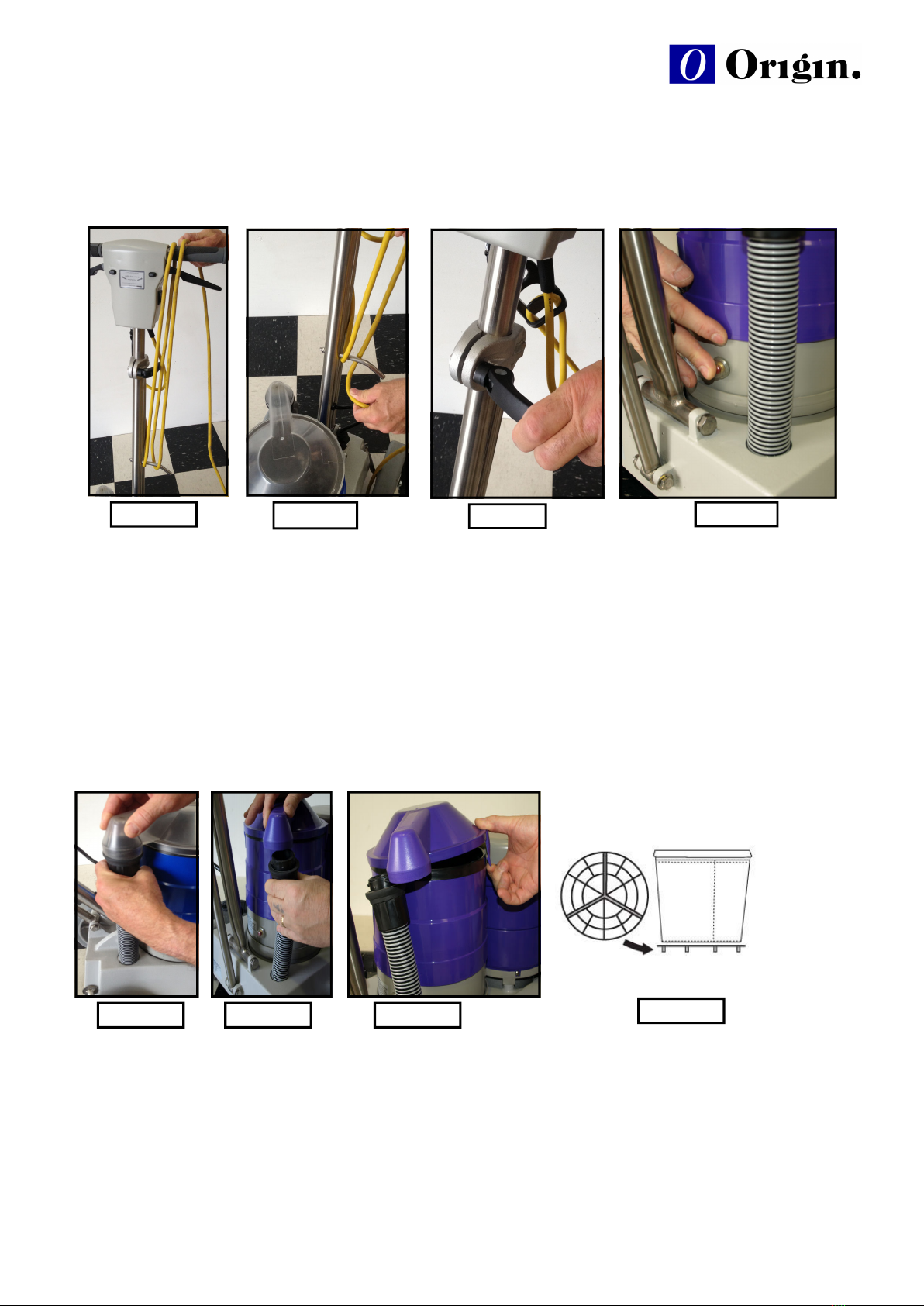

1. DO NOT leave this machine unattended when it is plugged in. Unplug from the outlet when not in use

and before fitting or removing the brush.

. DO NOT pick up building materials such as plaster dust, wood shavings, sand etc.

3. Use this machine only as described in this manual. Use only manufacturer’s recommended accessories

including the pads.

4. DO NOT use with a damaged electric cable.

5. DO NOT use if this machine has been left outdoors and exposed to rain or water. Return the machine

to an authorized dealer for examination.

6. DO NOT pull or carry the machine by the electric cable. DO NOT use the cable as a handle, close a

door on the cable, or pull the cable around sharp edges and corners.

7. DO NOT run machine over the cable.

8. KEEP the cable away from heated surfaces.

9. DO NOT unplug by pulling on the cable. To unplug, grasp the plug, not the cable. Wind the cable from

the machine end not from the plug, this will prevent the cable from twisting and extend its life.

10. DO NOT handle the plug or the machine with wet hands.

11. Keep hair, loose clothing, fingers, rags, steel wool and feet from openings, rotating brush and other

moving parts. Make sure no openings are blocked that will restrict airflow.

1 . DO NOT pick up hot coals, cigarette butts, matches or any hot, smoking or burning objects.

13. DO NOT pick up or run the brush over hard or sharp objects such as glass, nails, screws, coins, etc.

14. DO NOT use without all the filters in place. Use ONLY filters and accessories provided by the

manufacturer. Failure to do so will void the warranty.

15. Switch off all controls before plugging or unplugging this machine into an electrical outlet.

16. DO NOT pick up flammable or combustible materials or use this machine in the presence of explosive

liquids or vapours.

17. DO NOT use in an enclosed space filled with vapours given off by oil based paints, paint thinners,

flammable dust, powdered milk, or other explosive or toxic vapours. THIS IS NOT AN EXPLOSION

PROOF MACHINE.

18. Always store this machine indoors.

This appliance is not intended for use by young children or infirm persons, without proper super-

vision. Young children should be supervised to ensure that they do not play with this appliance.

DO NOT expose to rain and DO NOT pick up water or other li uids.

This machine is insulated for your protection. However, a shock can occur if the electric cable is damaged.

If the supply cable is damaged, it must be replaced by the manufacturer or its agent or retailer to ensure

the correct type of approved cable is supplied in order to avoid a hazard. Make sure that the cable is kept

clean to help highlight cable damage.