Osaki Power Tools PDB132 User manual

OPE ATO ’S MANUAL

Bench mounting Pillar Drill

PDB132

Suitable for DIY, not industrial use

Smooth running 350W motor for drilling

holes up to 13mm

5 speeds for versatility and performance

when drilling different materials

Tilting rise and fall work table

Operates from a standard 13amp plug

AVAILABLE F OM YOU DIST IBUTO

EC DECLA ATION OF CONFO MITY

Osaki Power Tools continually strives to improve its products. Specifications may change without prior notice.

OSAKI TOOLS Official Agents - APAN: MIKI TOOL TRADING CO. MIKI CITY, APAN.

EUROPE, MIDDLE EAST, AMERICA & AFRICA: KENNEDY TOOLS, WIGSTON, ENGLAND, LE18 2FS

DECLA ATION OF CONFO MITY

We hereby certify that OSAKI PDB132 Bench Pillar Drill

complies with all the relevant provisions of the following directives:

Electromagnetic Compatibility 2004/108/EC, Low Voltage 2006/95/EC and Machinery 2006/42/EC.

Standards applied: EN 61029-1/A12:2003, EN 55014-1/A2:2002, EN 55014-2/A1:2001,

EN 61000-3-2/A2:2005, EN 61000-3-3/A2:2005.

Official Agent

KENNEDY TOOLS

Wigston, Leicester, England, LE18 2FS.

Supplied by an ISO9001 approved company

Signed:

Date: February 2013 Name: Keith Rea Position: Group HSQE Manager

QUALITY GUA ANTEE & WA ANTY

OSAKI POWE TOOLS carry one years manufacturers warranty.

OSAKI POWE TOOLS are designed & produced

to the highest standards & specifications

OSAKI POWE TOOLS are fully guaranteed against

faulty materials & workmanship

Shoul they be foun to be efective, they will either be repaire or replace

free of charge (fair wear an tear an /or misuse excepte ).

This oes not affect your legal rights.

Please retain supplier invoice as proof of purchase.

Osaki Power Tools are esigne for DIY an hobby use only.

They are not covere by an in ustrial warranty. In ustrial use will invali ate this guarantee.

Osaki, Osaki Xtra-plus and the round Mitsudomoe logo are trade marks of Osaki Tools.

O DE CODE

OSA-279-9340K

© The Kennedy Group Ltd. 03/13

Supplie by an ISO9001 approve company

SYMBOLS USED WITH THIS P ODUCT

SAFETY INST UCTIONS

152

Man, Earth and the Universe

are forces that create an

immovable centre of balance . . . the

balance of power

“

”

Read operator’s

manual

Recycle

See page 14

WEEE

See page 14

European

Conformity

Warning RoHS

See page 14

Osaki Power Tools are committe to the Pro uction of a range of Quality Power Tools

that are esigne for high performance an long service life. By following the recommen e

safety an maintenance proce ures they will last for many years.

SPECIFIC OPE ATING HAZA DS

lAlways adhere to the processes and safety

warnings, which are stated in the instruction

manual.

GENE AL OPE ATING HAZA DS

lAlways ensure the mains power supply

corresponds to the power rating on the data label

on the Pillar Drill.

lAlways plug the Pillar Drill into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Check with a qualified electrician if you are in

doubt as to whether the outlet is properly

grounded.

lAlways disconnect from the electrical power

supply and ensure that the chuck has stopped

rotating before cleaning or carrying out user

maintenance.

lAlways ensure the maintenance of electrical

components is carried out by a suitably qualified

person.

lNev er op era te if an y p art s a re mis sin g o r

damaged.

lNever allow untrained persons to operate the

pillar drill.

lNever touch the metal plug pins when connecting

or removing the electrical plug.

WO KPLACE HAZA DS

lAlways keep the electric cable away from heat

and sharp edges.

lAlways use a RCD (Residual Current Device) to

provide protection against electric shock.

lAlways ensure all users are physically able and

competent to handle the size and weight of

items/components being drilled and have

received appropriate training to perform the task.

lNever run the Pillar Drill in areas exposed to

water or in damp conditions.

lNever direct jets of water or flammable liquids

over the Pillar Drill.

OTHE OSAKI P ODUCTS

314

SAFETY INST UCTIONS

PE SONAL P OTECTION

lAlways wear approved eye protection during

operation. Use safety glasses or goggles which

conform to BSEN136 or CE equivalent that

provide protection from the front and side. The

operator of the pillar drill is responsible for

following accepted eye, face, respiratory, hearing

and body protection.

lAlways ensure that all long hair and loose

clothing, ties, scarves, jewe llery, etc., are

secured or removed.

lAlways consult a doctor if numbness, tingling,

pain or whitening of the skin occurs. Repetitive

work motions, awkward positions and exposure

to v ib ratio n can c ause “ Re pet it ive St rai n

Injuries”.

SPECIFIC OPE ATING HAZA DS

lThe Pillar Drill must be mounted and firmly

anchored on a flat and level surface. When

selecting a suitable location for mounting this

machine consideration must be given to the

maximum length of the material to be drilled or

machined and the position of the operator.

lAlways ensure the electric cable is not damaged

before connecting the Pillar Drill to the electricity

supply.

lAlways use recommended attachments or parts

and make sure that they are kept sharp and

fitted correctly, that all the securing bolts are

tight and all guards are fitted and operating

correctly and that the chuck key and any other

adjustment tools have been removed.

lSelect the correct spindle speed for the size of

drill being used. See the instruction manual.

lWhen drilling use the correct cutting

lubricant/coolant for the material being drilled.

Use only sufficient to prevent the drill from

overheating and make sure that it is kept well

away from electrical components. Never use

water as a coolant.

lWhen drilling long lengths ensure that there is

adequate support at both ends of the material.

lNever use the Pillar Drill without the safety

guards in position and operating correctly.

lEnsure that the work piece is free from any nails

or other foreign objects that could damage the

drills and other cutting tools.

lAlway s sec ure t he wo rkpiec e in a s uitabl e

machine vice. Never try and secure the

workpiece with your hands.

Warning: Be aware that swarf can be very sharp,

hot and can fly off the rotating drill. When

handling swarf always wear suitable gloves.

Swarf should not be disposed of with domestic

waste, it should be disposed of at a recycling

centre.

lNever leave the Pillar Drill connected to the

electric supply when unattended.

lAlways switch off using the on/off switch when

the pillar drill is not in use.

lNever use the Pillar Drill without the guard

attached.

lNever deface the rating plate on the Pillar Drill.

lNever make any alterations to the Pillar Drill and

only use it for the task for which it has been

designed.

A comprehensive repair and service

facility is available through your

local Osaki agent.

MAINTENANCE

SE VICE & EPAI

THE ENVI ONMENT

Always dispose of unwanted tools, accessories and packaging materials in an environmentally

friendly manner.

For EU and EEA countries only.

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE) and its implementation in accordance with national law, electrical goods that have reached

the end of their life must be collected separately and returned to an environmentally compatible

recycling facility.

Do not dispose of electrical goods with domestic waste materials as inappropriate disposal may

cause potential hazards to the environment and human health.

For further information, please contact your local authority or the retailer from whom you purchased

the product.

This product does not contain any restricted substances in concentrations and applications which

are banned by the European RoHS Directive.

The drill requires very little maintenance apart from keeping all unpainted surfaces coated in light oil.

Keep the machine clear of swarf which should be disposed of in a proper manner and not put into

domestic refuse bins.

Always inspect and check the set up and adjustments before using the machine.

134

ELECT ICAL INFO MATION

In the United Kingdom, the ELECTRICITY AT WORK ACT 1989 requires all portable electrical appliances, if

used on business premises, to be tested by a qualified electrician, using a Portable Appliance Tester (PAT), at

least once a year. The HEALTH & SAFETY AT WORK ACT 1974 makes owners of electrical appliances

responsible for the safe condition of the appliance and the safety of its operator. If in any doubt about

electrical safety, contact a qualified electrician.

ELECTRICAL SAFETY

An RCCB (Residual Current Circuit Breaker) should be fitted in the mains electricity distribution board. If the

power supply is not protected by an RCCB, it is highly recommended that an RCD (Residual Current Device) is

used with all portable electrical products.

PLUG FITTING

A moulded UK 3 pin plug with ASTA/BS approval is already fitted for your safety.

If it becomes damaged, and needs replacing, cut off the plug and prepare the

wires. Use the following instructions:

a) Connect the GREEN/YELLOW earth wire to the earth terminal marked either

‘E’ or with the earth symbol‘ ’.

b) Connect the BROWN live wire to the live terminal marked ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal marked ‘ N’.

d) After wiring, check there are no bare wires, that all wires have been correctly

connected, that the cable external insulation extends beyond the cable

restraint and that the restraint is tight.

EXTENSION REELS

When a cable extension reel is used it should be fully unwound before being

connected. Use at least 1.5mm2 section cable or to be absolutely sure use

2.5mm2section cable.

Yellow & Green = Earth wire

Cable restraint

UK

ONLY

Brown = Live wire

Blue = Neutral wire

5 amp

fuse

SPECIFICATIONS

Model Number PDB132

Order Code OSA-279-9340K

Motor Input Capacity 350W

Motor Output Capacity 210W

Motor Supply Voltage 230V - 50Hz

Spindle Travel 50mm

Spindle Taper MT2

Table Si e 156 x 160mm

Base Si e 314 x 200mm

Column Diameter Æ46mm

Drilling Speed 580-2650 PM

Sound Power 75.1 dBA

Sound Pressure 62.1 dBA

Max distance from spindle axis to surface of column 104mm

Max distance from spindle end to surface of table 200mm

Max distance from spindle end to surface of base 290mm

Overall Size 355 x 225 x 580mm

Net Weight 15KG

T OUBLESHOOTING

POSSIBLE CAUSE

1. Faulty fuse.

2. The switch is faulty.

3. Faulty wiring.

4. Faulty motor

1. ‘ V’ belt defective

2. ‘ V’ belt too loose

1. Loose drive belts

2. The spindle may be

running dry

3. Loose pulleys

1. The drill may be blunt

2. Incorrect speed.

3. Feeding too slow

1. Bit deformed

2. Bearings worn down in

the drill head

3. Bit badly fitted

4. Drill chuck defective

1. Poorly fitting bit —

Check for straightness

or dirt on the bit or in

the chuck stopping it

from centring correctly

in the chuck.

2. Worn drive spindle

bearings

1. Overloaded motor

2. Insufficient mains

voltage

1. Quill spring not working

SOLUTION

1. Replace the fuse with a new one of the

correct amp rating.

2. Have it tested by a qualified person and if

neccessary replace with a new one.

3. This must be checked by a qualified person.

4. This must be checked by a qualified person.

1. Replace ‘ V’ belt

2. Re-tension as on page 11

1. Check the tension (see page 11). If the

tension is OK, check the belts for wear and

replace if neccessary

2. Lubricate with grease

3. Tighten set screw in pulleys

1. This may have been caused by overheating

due to too much pressure being applied or

not enough coolant being used. Sharpen or

replace the bit with a new one

2. Change speed - see Chart opposite

3. Feed fast enough to allow the bit to cut

1. Replace bit

2. Have the bearings in the drill head replaced

3. Refit the drill bit in the chuck

4. Replace the chuck

1. Remove and clean chuck and bit or replace

bit if damaged

2. With the machine switched off, check for

play in the drive spindle. If there is

movement, the bearings must be removed,

inspected and replaced if neccessary by a

qualified person

1. Disconnect immediately and have it

checked by an authorized repairer

1. Adjust as detailed on page 8

FAULT

The drill will not start.

Drive spindle does not

turn

Screeching noise when

drilling

The bit burns or smokes

Bit runs off-centre

Excessive vibration when

drilling

Motor overheating and

lack of power

Drill spindle and chuck

does not return to starting

point

Repairs must be performed in a dirt-free environment by a qualified person who is familiar

with this type of equipment. Make sure the machine is disconnected from the power supply

prior to carrying out any repair or maintenance work

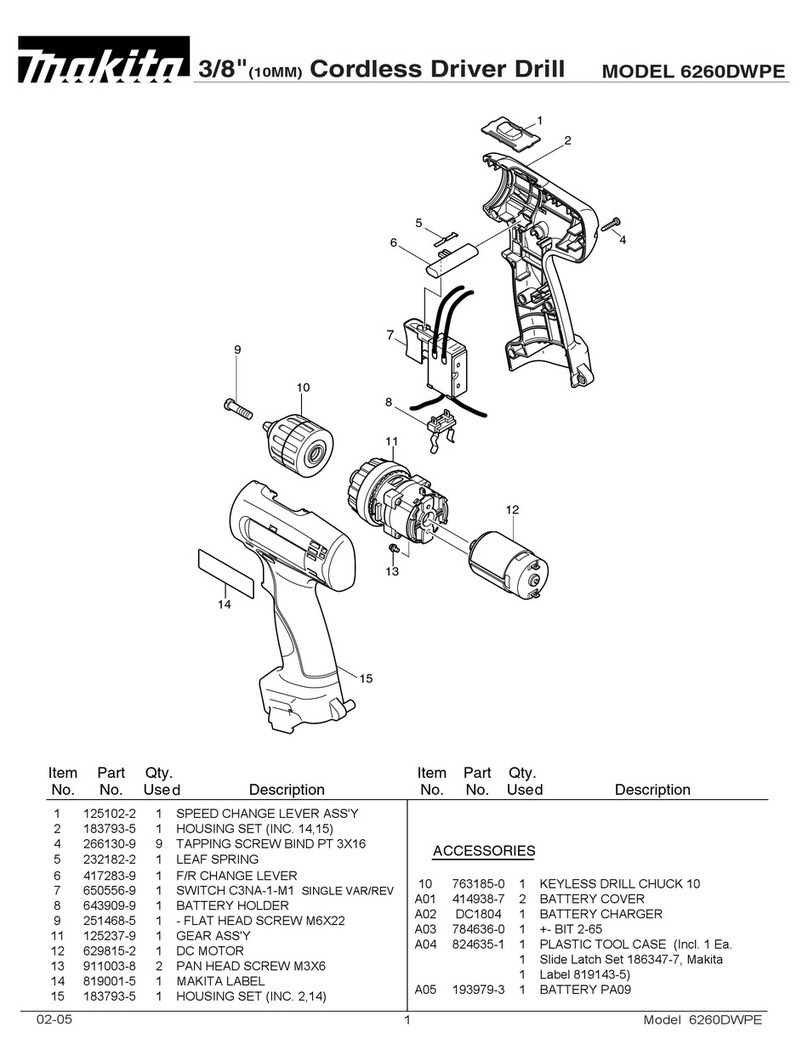

BOX CONTENTS

1. Drill Head Stock & Motor Assembly

2. Chuck, Chuck Key & Hex. Key

3. Column Mounting Bolts

4. Column

5. Table

6. Chuck Guard

7. Base

8. Depth Stop

2

3

4

8

7

6

59

Fig.1

512

SPA ES

For spare parts or servicing please contact your nearest agent. Remember to quote tool model number and

spare part number when ordering spares. The use of other than genuine OSAKI replacement* parts may

result in safety hazards, decreased tool performance and increased maintenance. When disposing of

components, etc. ensure that relevant environmental procedures are carried out.

Chuck Guard OSA-298-1600S

‘V’-Belt OSA-298-1601S

Shaft OSA-298-1602S

Rating Plate/Label OSA-298-1603S

*(OSAKI recommends the use of

KENNEDY replacement chucks)

SWITCHING THE PILLAR DRILL

ON OR OFF

When all the the desired settings have been

made, you switch the Pillar Drill on by pressing

the Green Button marked I (Fig. 34a) or off by

prressing the Red Button marked with an O

(Fig. 34b)

OPE ATION

Fig.34

PULLEY ARRANGEMENT/SPINDLE SPEEDS

Fig.35 1=2650 RPM

2=1650 RPM

3=1220 RPM

4=850 RPM

5=580 RPM

DRILLING SPEED CHART (GUIDE ONLY)

aterial to be drilled

Size Steel Cast Iron Gun etal Aluminum Plastics Wood

(mm) Drill Speed (RP )

3 2500 2500 2500 2500 2500 2500

4 2500 2500 2500 2500 2500 2500

5 1750 2500 2500 2500 2500 2500

6 1750 2500 2500 2500 2500 2500

7 1250 1750 2500 2500 2500 2500

8 1250 1750 2500 2500 2500 2500

9 900 1250 1750 2500 2500 2500

10 900 1250 1750 1750 2500 2500

11 600 900 1250 1750 1750 2500

12 600 900 1250 1750 1750 1750

13 600 600 900 1250 1750 1750

Fig.36

Drill

34b 34a

ASSEMBLY

116

Caution! This packaging contains sharp objects. Take care when unpacking.

Remove the Pillar Drill, together with the accessories supplied, from the

packaging. Check carefully to ensure that the Pillar Drill is in good condition

and account for all the accessories listed on Pg.5. Also make sure that all the

accessories are complete. If any parts are found to be missing or damaged,

the Pillar Drill and its accessories should be returned together in their original

packaging to the retailer. Do not throw the packaging away, keep it safe

throughout the guarantee period, then recycle if possible, otherwise dispose

of it by the proper means. Do not let children play with empty plastic bags

due to the risk of suffocation.

LOCATING THE ACHINE

When determining where to locate or

permanently fix the Pillar Drill, consideration

must be given to the following points.

Is there a suitable mains outlet socket near by.

The Pillar Drill should be permanently fixed to a

level bench, solid enough to take the fixings and

stable enough to carry the weight of the

machine and items to be machined upon it.

ASSE BLY

Lift out the base plate, remove the protective

paper and place the base plate on a workbench

or the floor. Locate the chuck, chuck key, three

bolts, hexagonal key, telescopic guard and drift

key and place to one side for time being.

Lift out the worktable, drill head, motor

assembly and the column, remove the

protective paper and place them onto a

workbench.

SECURING THE BASE PLATE

Select a suitable location for the drill on a

bench for mounting the base plate. A suitable

mains supply socket must also be accessible

for the plug.

Locate the base plate in the selected position.

Select Nuts, Bolts and washers of a suitable

length to go through the base plate and bench (not supplied).

Using the base plate as a template drill two holes in the bench with a suitable bit. Insert the bolts through

the base plate and bench. Add the washers and tighten the nuts onto the base plate. Do not over tighten

as this could crack the cast base plate.

Fig.2

Fig.3 Fig.4

Fig.5 Fig.6

Fig.7 Fig.8

Fig.26

OPE ATION

BELT TENSION

When the desired pulley arrangement has been achieved, undo the wing nut (Fig.31a) to tension the drive

belt by inserting

a large

screwdriver or

small pry bar

between the

motor and the

drill head

casting and

lever them

apart. Tighten the wing nut to lock the slide bar. To check that the correct tension has been achieved,

press your finger onto the centre of the drive belt (Fig.32). The drive belt should move approximately 13mm.

Re-tighten the two wing nuts to lock the motor onto the two slide bars.

Fig.32

Fig.31

GENERAL GUIDELINES FOR DRILLING

Always centre punch the position for driIIing. A centre punch

is a pointed tool that marks the material to be drilled with a

small indent. It stops the drill bit moving from the desired

position. Always start by drilling a small pilot hole and

gradually progress in drill diameter. When drilling metal,

lubricate the drill tip with oil.

NEVER cool with water or water based lubricant otherwise

an electric shock could occur. DO NOT use oil when drilling

copper or brass. Care should be taken when drilling copper

and brass as the drill bit will be prone to jamming. Small

diameter drills require a higher speed and as the drill

diameter increases the slower the speed required. The

following drilling speed chart is a guide only and only covers

the more common materials, drill diameters and speeds.

D ILLING GUIDELINES

31a

Fig.33

FITTING THE COLU N (Fig.2, 3 & 4)

Align the holes in the column support base with

the threaded holes in the base plate and fit

using the three bolts supplied. Do not over

tighten as this could crack the cast base plate

and column support.

FITTING THE TABLE

Take the table and offer it to the column (Fig.5),

loosening the table support clamp if

neccessary. Lower the table onto the column

and position in line with the base as shown in

(Fig.6) and tighten using the clamping handle.

FITTING THE DRILL HEAD AND

OTOR ASSE BLY (Fig.7 & 8)

Locate the two grub screws in the side of the drill

head and motor assembly (Fig.8). Using a

hexagonal key slacken the two grub screws. Lift the

drill head and motor assembly, lower it onto the

column (Fig.7). Make sure that it slides down and

locates fully on the column. Position the head

stock and motor assembly, with the Stop/Start

switch facing left and aligned with the base plate.

Tighten the two grub screws (Fig.8) to secure the

drill head and motor assembly into place. Retain

the hexagonal key for future adjustments.

FITTING THE TELESCOPIC CHUCK

GUARD AND DEPTH STOP (Fig.9 — 19)

Position the clear plastic shield into the red collar

and secure in place with the two small cross head

screws. Insert the hexagonal nut into the recess on

the red plastic frame (Fig.9) then insert the

threaded depth stop shaft into the frame and make

finger tight (Fig.10 & 11). Insert the shaft through

the hole in the drill head casting (Fig.13) Place the

adjusting and locking nuts onto the shaft (Fig.14).

Place the depth indicator over the top of the shaft

so that it points to the depth scale on the front of

the drill head Fig. 15, 16 & 18). Place over the

chuck spindle and locate onto the drill head collar

(Fig.16). Tighten the cross-head clamping screw but

don’t over tighten as this may break the plastic

body (Fig.17). Check that the guard lifts easily and

stays lifted to change drills/cutting tools (Fig.19). Fig.18Fig.17

ASSEMBLY

710

Fig.10

Fig.12

Fig.14

Fig.9

Fig.11

Fig.13

Fig.15 Fig.16

USING THE 3 JAW CHUCK

Select the drill bit required and from the drill speed chart

(Page.12 - Fig.36) select the correct speed and change

settings as per the section CHANGING THE SPINDLE SPEED

below. Open the jaws and insert the drill shank centrally into

the chuck (Fig.27). Rotate the chuck by hand until the jaws grip

the drill bit. The chuck has three holes around the chuck body.

Using the chuck key, exert an even torque to tighten, moving

from one whole to the next until all three holes have been

covered (Fig.28). Continue with the steady torque until tight.

Do not over tighten otherwise you will have difficulty removing

the drill bit.

SETTING THE DEPTH STOP

To set the depth stop located on the Chuck Guard:

1. Rotate the handles towards you until the indicator aligns

up with the depth required on the scale.

2. When the depth stop arrow is aligned with the depth

required, spin the adjusting nut down until it rests on the

flange that the shaft travels through (Fig.29).

3. Check that the depth indicating arrow is pointing to the

depth required, then tighten the locking nut down onto

the adjusting nut.

The example shown in Fig.29 shows the depth stop set at

40mm with the adjusting and locking nuts stopping at the

flange on the drill head casting.

CHANGING THE SPINDLE SPEED (Fig.30 - 36)

Unscrew the cross head screw securing the pulley guard.

Lift open the pulley guard to expose the pulley system

(Fig.30). Determine the spindle speed required. Identify the

pulley arrangement that gives the nearest spindle speed to

that required by referring to the drill speed chart (Fig.36).

To release the tension on the drive belt slacken the wing nut

located on the side of the casting (Fig.31a), move the motor

close to the drill head on the slide bar and tighten the wing nut, this will release the tension on the drive

belt and hold in position whilst changing belt settings.

To move the drive belt to the desired pulley arrangement. Push the belt on the largest drive spindle pulley

towards the next smallest pulley and at the same time rotate the drive spindle by hand until the drive belt

locates onto the next smallest pulley. Repeat this procedure on the motor pulley until the desired pulley

arrangement has been achieved.

For pulley arrangements see (Fig.35) page 12.

Fig.28

Fig.27

Fig.29

Fig.30

OPE ATION

98

FITTING THE CHUCK

The chuck has a taper fitting, simply place it onto

the spindle adaptor and tap with a soft rubber

mallet (Fig.19 & 20). This is enough to secure in

it place and it should be tight enough. To make

doubly sure, place a piece of wood on the table

and wind the manual feed handle to bring the

chuck down onto the wood pressing the chuck

tighter onto the spindle adaptor. To remove or

replace the chuck, tap with a soft mallet.

ADJUSTING THE TABLE HEIGHT

To adjust the table height, slacken the

clamping lever at the rear of the table support

assembly (Fig.6). Raise the table up or down to

desired height. When the desired height has

been achieved, do not forget to re-secure the

clamping lever.

TILTING THE TABLE ± 45°

Locate the securing bolt underneath the table

(Fig.21). With a suitable spanner/wrench

loosen the bolt. On the table support assembly

casting there is a graduated 0 - 45°scale

(Fig.22). Set the table to the required angle

and re-tighten the bolt.

NOTE: The graduated scale is for guidance

only. We recommend the use of an engineers

protractor when setting any angles.

WORK TABLE SWING 360°

The work table can swing through 18O°to the rear of the Pillar Drill in each direction 36O°. This will allow

larger work pieces to be accommodated on the base plate. Simply unclamp the table (Fig.6) and rotate the

table either clockwise or anti-clockwise to the rear of the Pillar Drill (Fig.23).

SPINDLE PLAY

Locate the spindle play adjustment set screw (Pic.24a). Loosen the lock nut and finger tighten the grub

screw. Hold the grub screw into position with a screwdriver and tighten the lock nut.

Fig.19

ASSEMBLY

Fig.20

SETTING UP & ADJUSTMENT

Fig.21 Fig.22

Fig.23 Fig.24

24a

QUILL SPRING ADJUST ENT

WARNING: The quill spring is under extreme tension.

Adjustment is normally only required after many hours of

use when It fails to return the spindle to its uppermost

position. The quill spring is located in a chrome housing

on the opposite side of the feed shaft boss and returns

the spindle to its uppermost position. With the spindle

in its uppermost position it can be seen that the chrome

cover has a total of three notches (Fig.25b) cut into the

edge that align with the cast body of the head stock.

One of these notches is located over a cast peg

(Fig.25a) that is part of the main casting.

WARNING: Before slackening the lock nuts ensure that

the chrome housing is held securely with a suitable grip

or wrench. If not held securely the quill spring will fully

uncoil.

Carefully slacken the lock nuts (Fig.25c) only enough to allow the chrome housing to be pulled out far

enough to just clear the cast peg (Fig.25a) while holding the chrome cover with suitable grips. The spring

is still under tension and will try to uncoil as soon as it is released so be sure to resist the torque. As

soon as the chrome housing is able to clear the cast peg, turn the chrome housing in an anti-clockwise

direction until the next notch locates onto the peg. While holding the chrome housing in this position

tighten the lock nuts. Do not over tighten or you will damage the chrome cover.

USING A ACHINE VICE

WARNING: The drill should never be used without the work piece being securely held in a machine vice or

clamped directly to the drill table. The drill table is

designed to accept a variety of machine vices which can

be fastened directly to the drill table; (Fig.26) shows an

example of the type of machine vice required.

Always secure the vice to the table with bolts, washers

and nuts. If the drill jams into the work piece an

unsecured machine vice will spin out of control causing

the drill to snap and possibly injure the operator.

Fig.25

25a

25b

25c

OPE ATION

SETTING UP & ADJUSTMENT

Fig.26

Table of contents

Other Osaki Power Tools Drill manuals