Oscimed PSV User manual

Page 1/5

Version : V1.0

Instructions for maintenance for cast cutter saw

OSCIMED PSV

Remark: see also the spare parts list.

1 Be sure to observe scrupulously the safety instructions

- Always take the plug off before doing whichever intervention on the device, or when

the device remains unattended or within reach of children or persons who are not

responsible for their actions.

- The maintenance and repairs must be provided by specialized persons; the possibly

damaged parts will be replaced by original spare parts.

- Every modification of the device in comparison with its original version is strictly

forbidden.

- Check that the socket in compliance with the plug of the device.

- Check that the indicated voltage on the motor block is in compliance with the used

power source.

- Never let the device running unattended.

- Do not pull neither lift the device when using the electric cable.

2Technical description

2.1 The electrical power supply

Supplied from a socket by a cable which passes through a transformer reducing voltage

to 24 VDC, it is optimal for the security. The device complied with the latest version of

medical standards EN 60601.

2.2 The electro-mechanical drive

The oscillating movement of the blade is made by a DC motor and a mechanical device,

which is made from high quality materials, with low wear and without maintenance. The

motor and the high lifespan sensor switch are driven by a microprocessor card.

The electromechanical device is mount trough anti-noise rubbers on the body of the

cutter to avoid vibrations in the hand and noise. The switch, situated closed to the user’s

hand, is a contactless long life time sensor.

2.3 The cutting blades

The blades have a synthetic coupling center. A special lock nut makes it easy to install or

change the blade without any tool.

Page 2/5

Version : V1.0

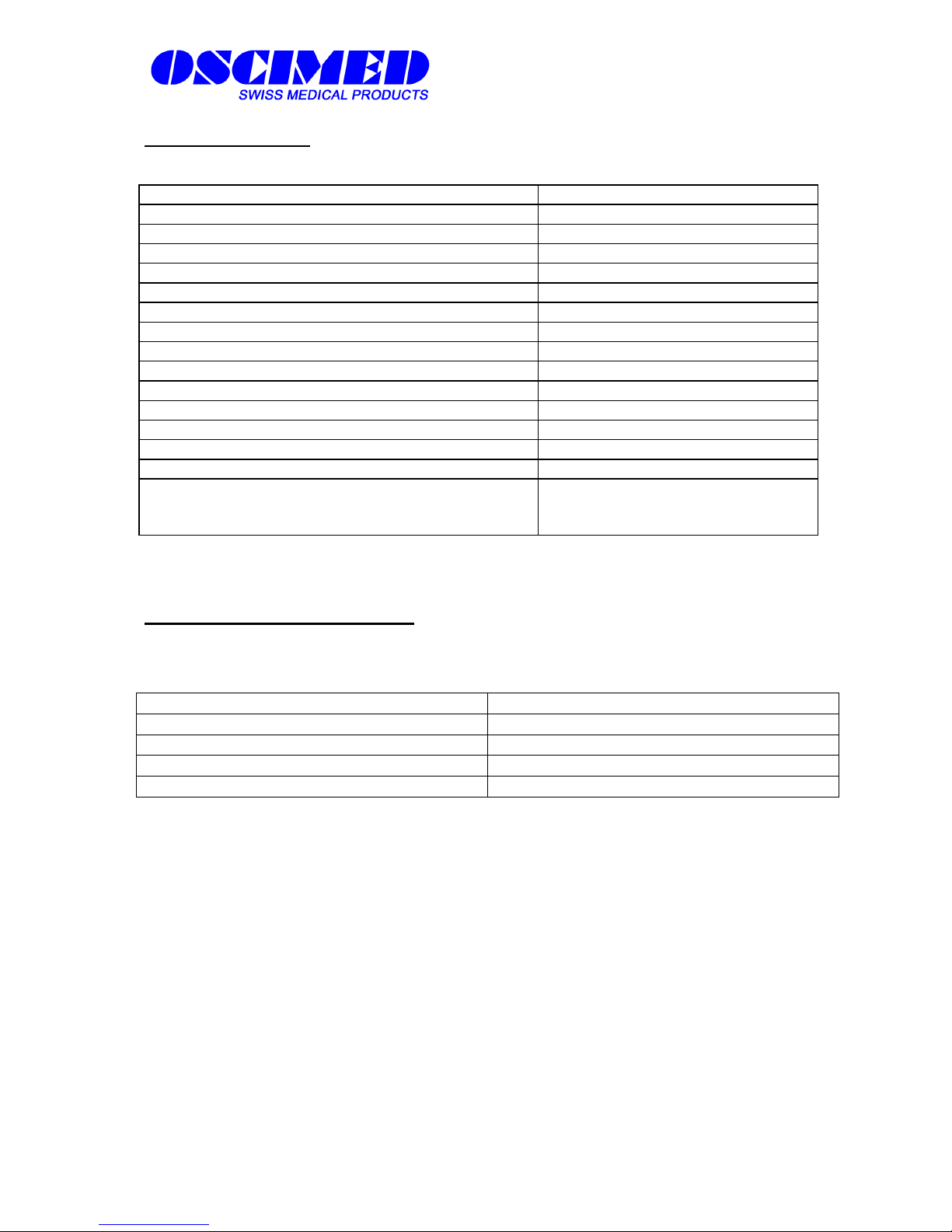

2.4 Technical data

Main voltage

85-264 VAC

Electricity network frequency

50-60 Hz

Power

200 VA

Cycle of use

45 minutes on / 15 minutes off.

Length of the saw

255 mm

Diameter

50 mm

Weight

890 gr

Speed of the motor / frequency

14’500 rpm

Oscillating angle of blade

6.2°

Stroke at the end of the blade diameter 65mm

3.50 mm

Length of power supply cable

1.10 m

Length of 24 VDC cable

3.00 m

Noise level

63 dBA

European directive 2007/47/CE

EN 60601 classe 1

Protection

IP 20

Storage, carriage and use condition.

Temperature: 0 - 35° C

Humidity: 0 - 90%

Pressure : 900 - 1080 hpa

3 Maintenance schedule

Disconnect the power supply before any maintenance or cleaning operation.

Maintenance

Frequency

General cleaning and disinfection

6 months

Main device check

6 months

Blade check

continuously

Page 3/5

Version : V1.0

4Current maintenance operations

4.1 General Cleaning and disinfection

Wipe clean with a damp rag. Do neither immerse the saw in water nor every other liquid,

nor clean it with a shower.

For disinfection, we recommend the following wipes: WIP’ ANIOS PREMIUM from the

company ANIOS or the spray SURFA_SAFE.

4.2 Main device check

-Check both electric cables in particular that the cables is damaged and no copper is

visible.

- Check that the oscillating shaft and the switch are not blocked in their movements by an

accumulation of sawing wastes, plaster dusts.

-Check visually the appliance and the main power supply box to detect damages like

cracks, or missing screw.

-Check that the blade lock nut maintain well the blade onto the shaft without any gap.

The blade lock nut must not turn too easily, if necessary change it.

-Check that the vacuum nozzle is clean in order to offer a good visibility.

4.2 Saw blade check

User has to use the device with good blades to insure safety and easy use. The teeth of

the blade must be sharp enough. If necessary change the blade and make sure of using

the right type of blade for the right cast material.

For synthetic casts, use blades with a BLUE center.

For normal plaster of Paris, use blades with a WHITE center.

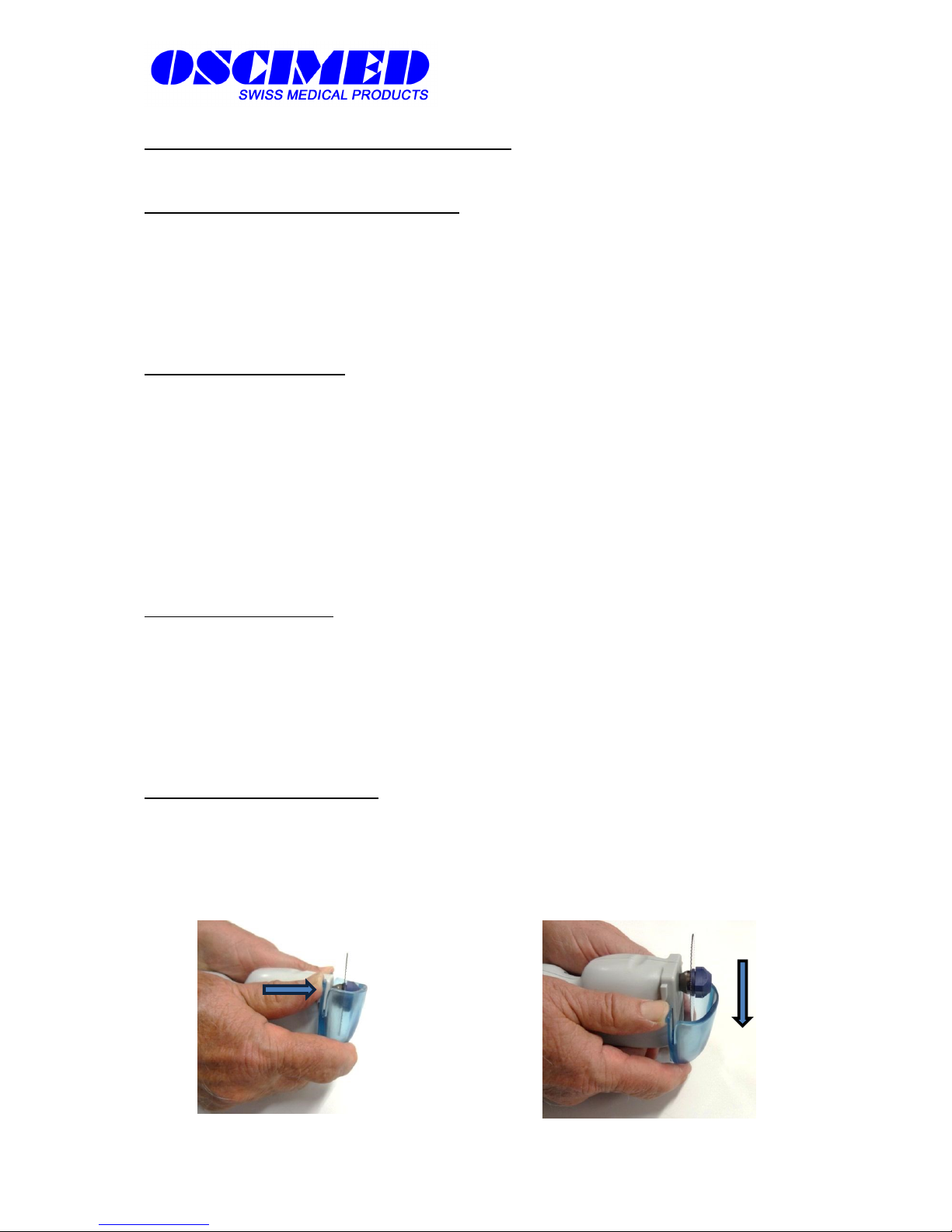

4.3 Vacuum nozzle change

Then remove the vacuum nozzle to reach the blade, by pushing the supple parts on

both sides in order to release the nozzle and slide it up.

Page 4/5

Version : V1.0

Set the nozzle back by inserting it in the guide and push down to the bottom till the

automatic lock.

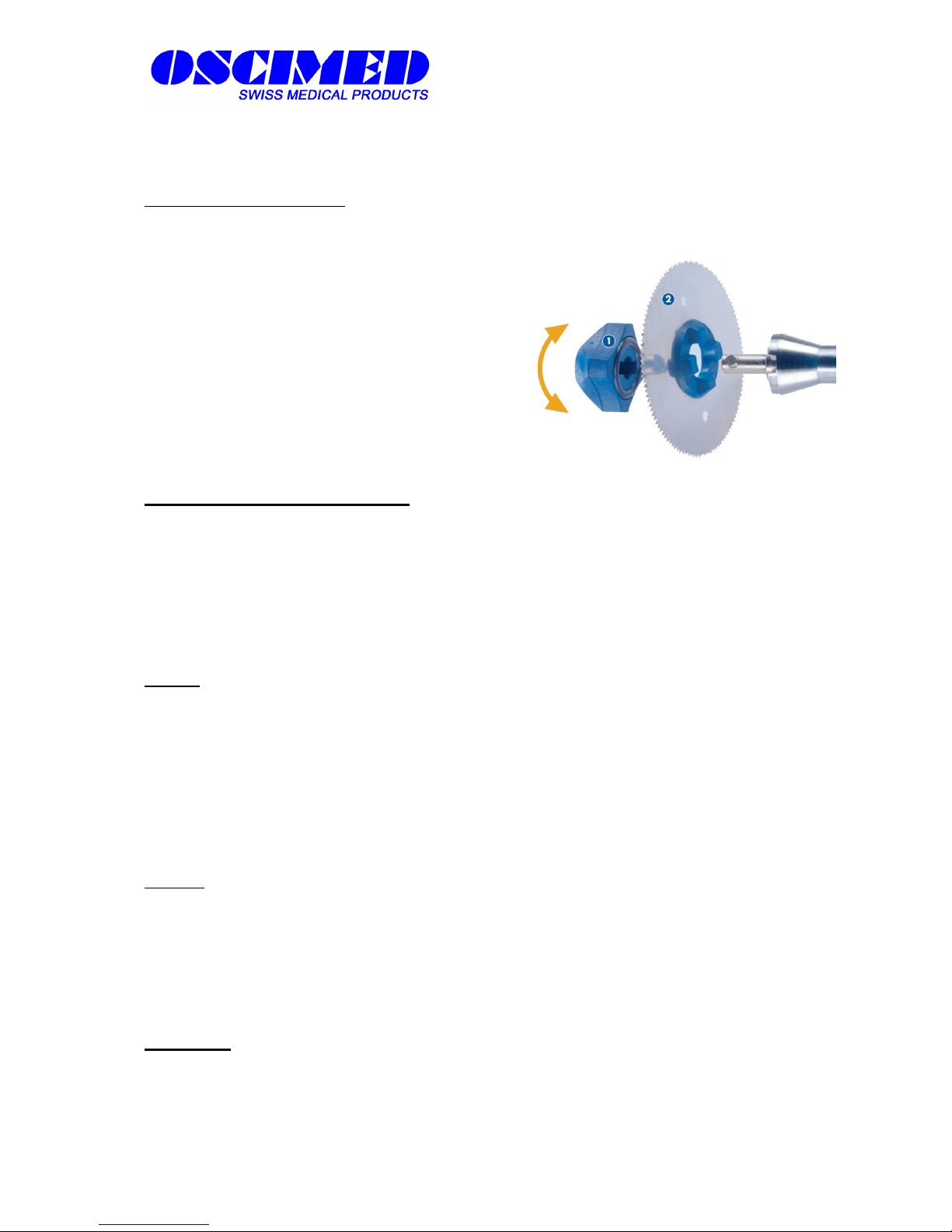

4.4 Saw blade change

First disconnect the power supply.

Remove the vacuum nozzle to reach the

blade.

Turn the blue blade lock nut (1) a quarter-

turn and pull it out. To remove the blade,

incline it a little and pull out.

Set the new blade (2) on notched spindle,

return the lock nut and turn back a quarter-

turn on its internal locking notch (1).

5 Main troubleshooting

See drawing at the last page and the spare parts list.

In case of breakdown, apply this first check:

Press the start button.

Case 1: the motor doesn’t turn.

Check the voltage at the output of the power supply (2). It must be 24 VDC. If not, please

change it.

If the power supply is ok, please check the voltage at the input of the electronic card (8).

If not please change the cable (4).

If the voltage is 24 VDC, then change the motor (6) and / or the electronic card (8) and

/or the switch (5)

Case 2: the motor turn, but the saw doesn’t vibrate properly

Open the main housing (5) by removing the 3 fixation screws.

Open the front cover (10) by removing the 4 screws and check that the lever (13) is well

fixed to the oscillating shaft and that rod (13) seems to be ok.

If above parts are ok, then check that the eccentric shaft (7) turn when the motor turn.

Important: After this mechanical check, please change preventively the 3 seals (16).

Page 5/5

Version : V1.0

Manufacturer’s address: OSCIMED SA - Allée du Quartz 3 - CH-2300 La Chaux-de-Fonds

Table of contents