2/4

2) Instruction for regular maintenance

a) The SPD must be isolated from the circuit by switching off the isolating switch

on the electric input side of the SPD, or removing the Backup Fuse shown in

Table 1, to provide protection from an electric shock.

b) When measuring an insulation resistance of the SPD or conducting voltage

withstand test, disconnect the SPD main unit from the fixing base. (Ref: Fig.1)

3) In the unlikely event of failure of the SPD or if there is an operation of isolating switch off or cut off the Backup

Fuse:

a) Personnel without authorization to work on electrical circuitry -immediately contact the relevant authorized

personnel but do NOT touch the SPD.

b) Authorized person-During inspection of the SPD, it must be isolated from the circuit by switching off the

isolating switch on the electric input side of the SPD, or removing the Backup Fuse shown in Table.1, to prevent

an electric shock. For details of the inspection procedure, refer to ”Regular maintenance” described in item 5. of

this manual.

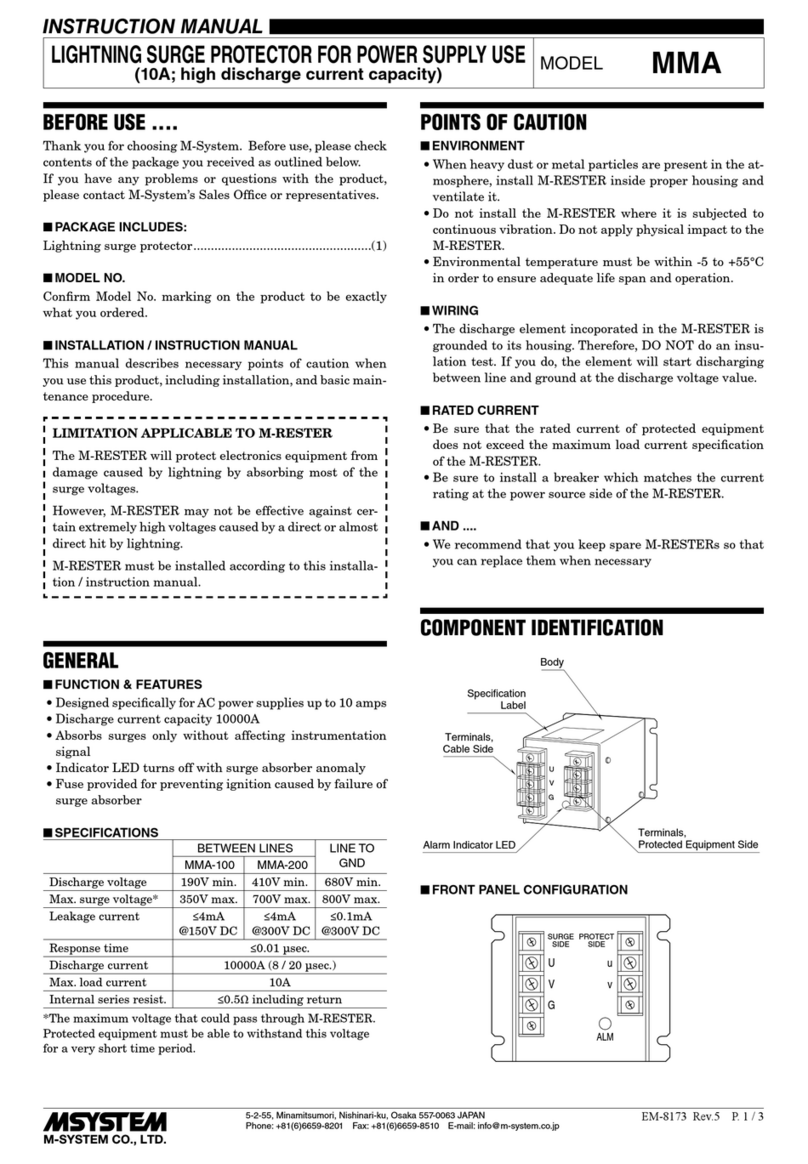

2. Installation method of the SPD

While installing the SPD, do the countermeasures

against an electric shock.

1) The SPD should be installed on DIN rail only.

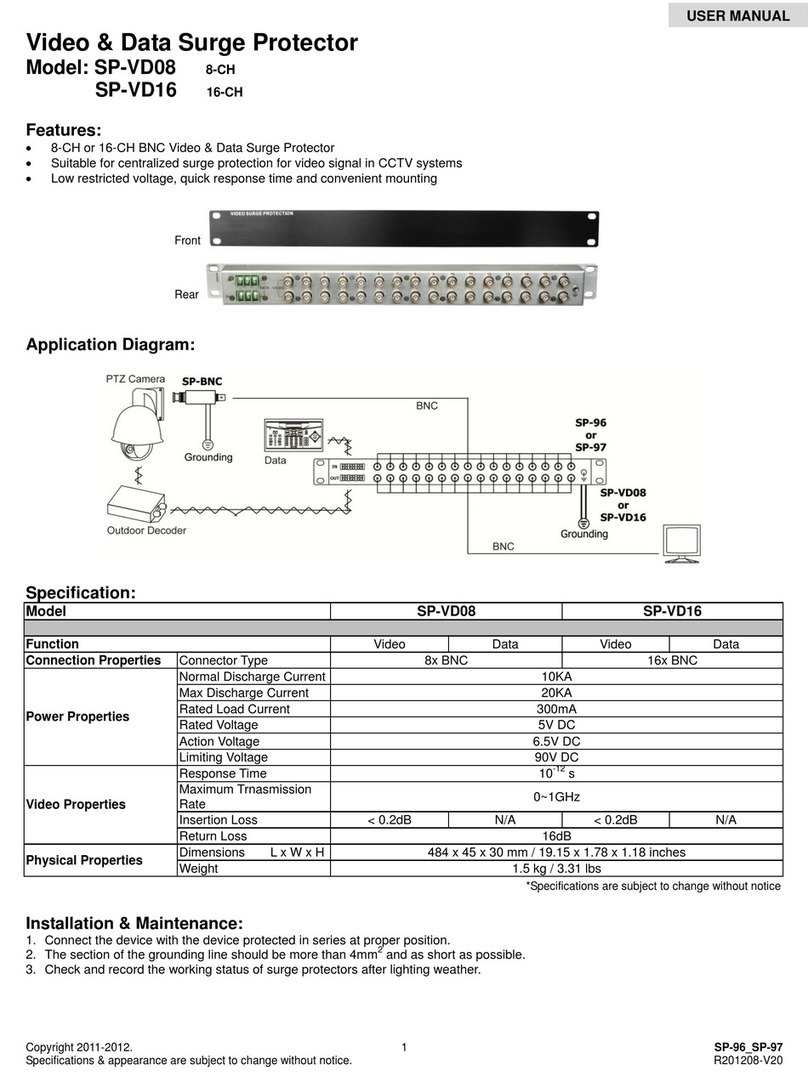

a) Installation method (Ref.Fig.2) :

After positioning the fixing base on DIN rail,

push the fixing base into DIN rail until locking

the slider on to the DIN rail.

b) Removing method (Ref.Fig.3) :

Pull the slider by using screw driver and pull off

the fixing base from DIN rail.

2) For connection of electric wires, use crimp terminals provided with an insulation cover. The wires should be

securely connected to L/N and PE terminals of the SPD -torque for the terminal screw should be 2.0~4.0N・m.

Minimum conductor size for the insulated wires used to connect the SPD should be 1.5mm2solid or flexible and

maximum conductor size should be 35mm2stranded or 25mm2flexible. Keep the wires used for the connection as

short as possible.

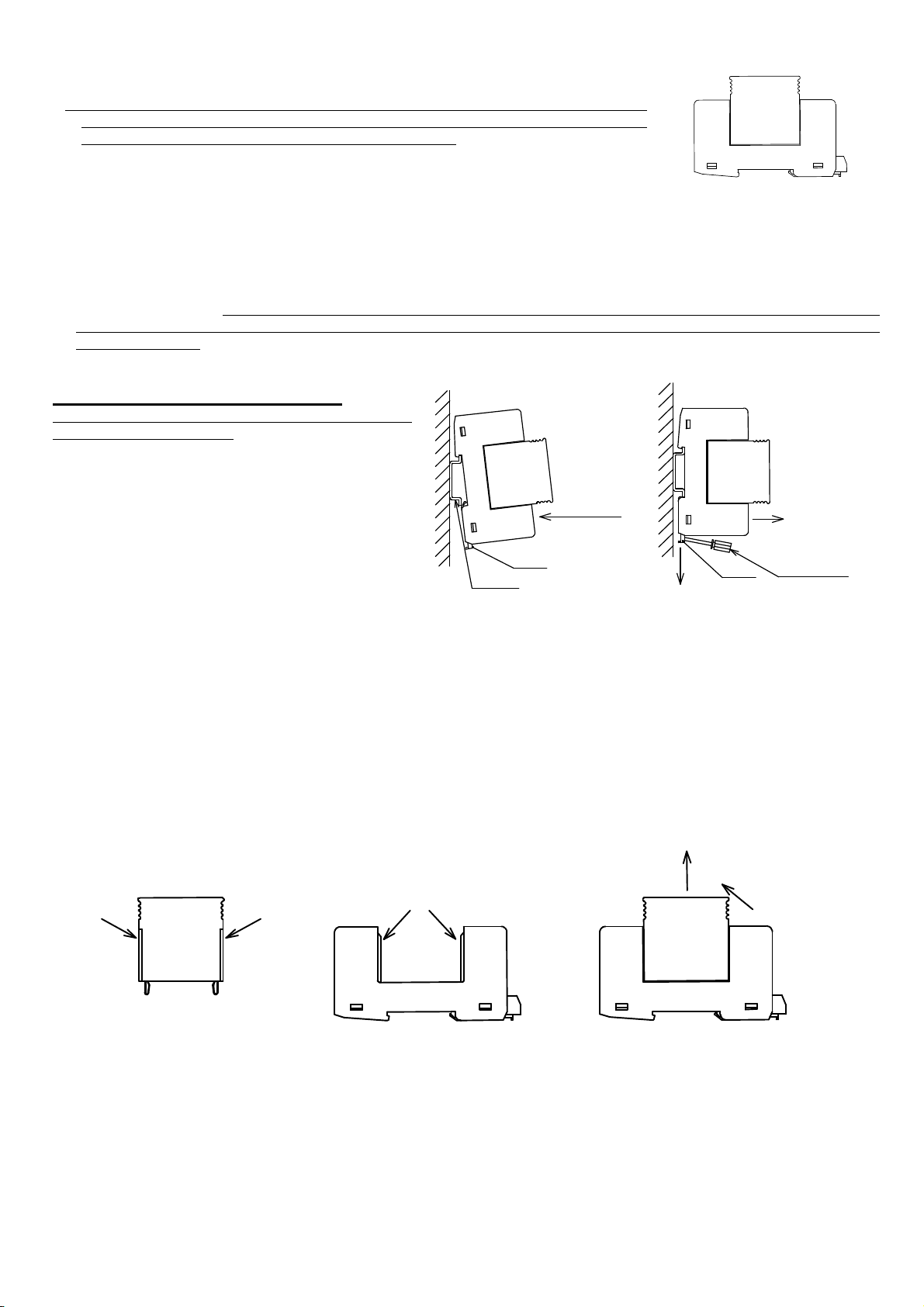

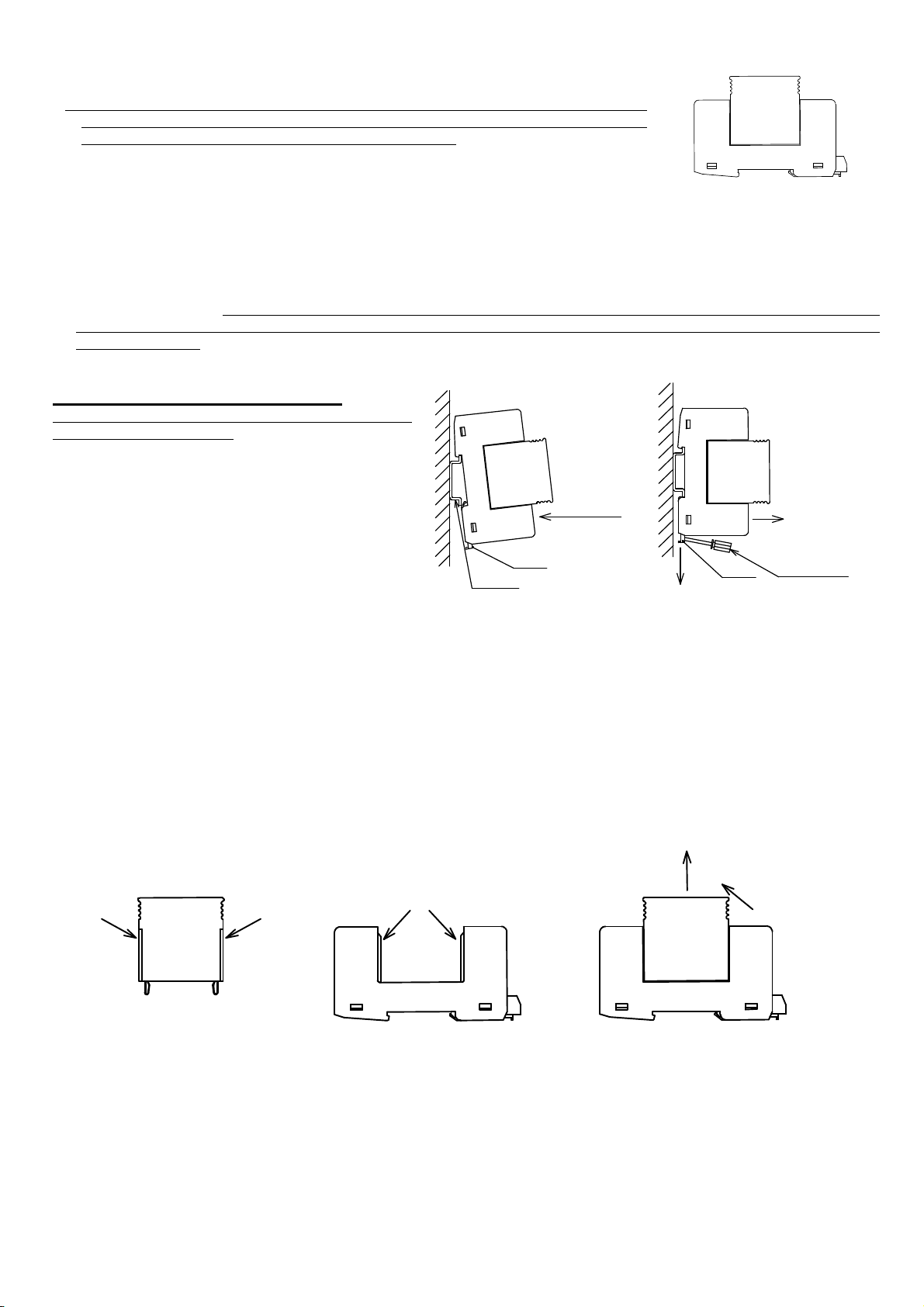

3) Installation and removing method of the SPD main unit (Ref : Fig.4, 5, 6, 7 )

a) When installing the SPD main unit, the concave of the SPD main unit (①part) should be fitted in the convex of

the fixing base(②part). Push the SPD main unit down to the fixing base securely until the end. If the SPD main

unit is not put in the fixing base until the end, the SPD may be no functioned normally.

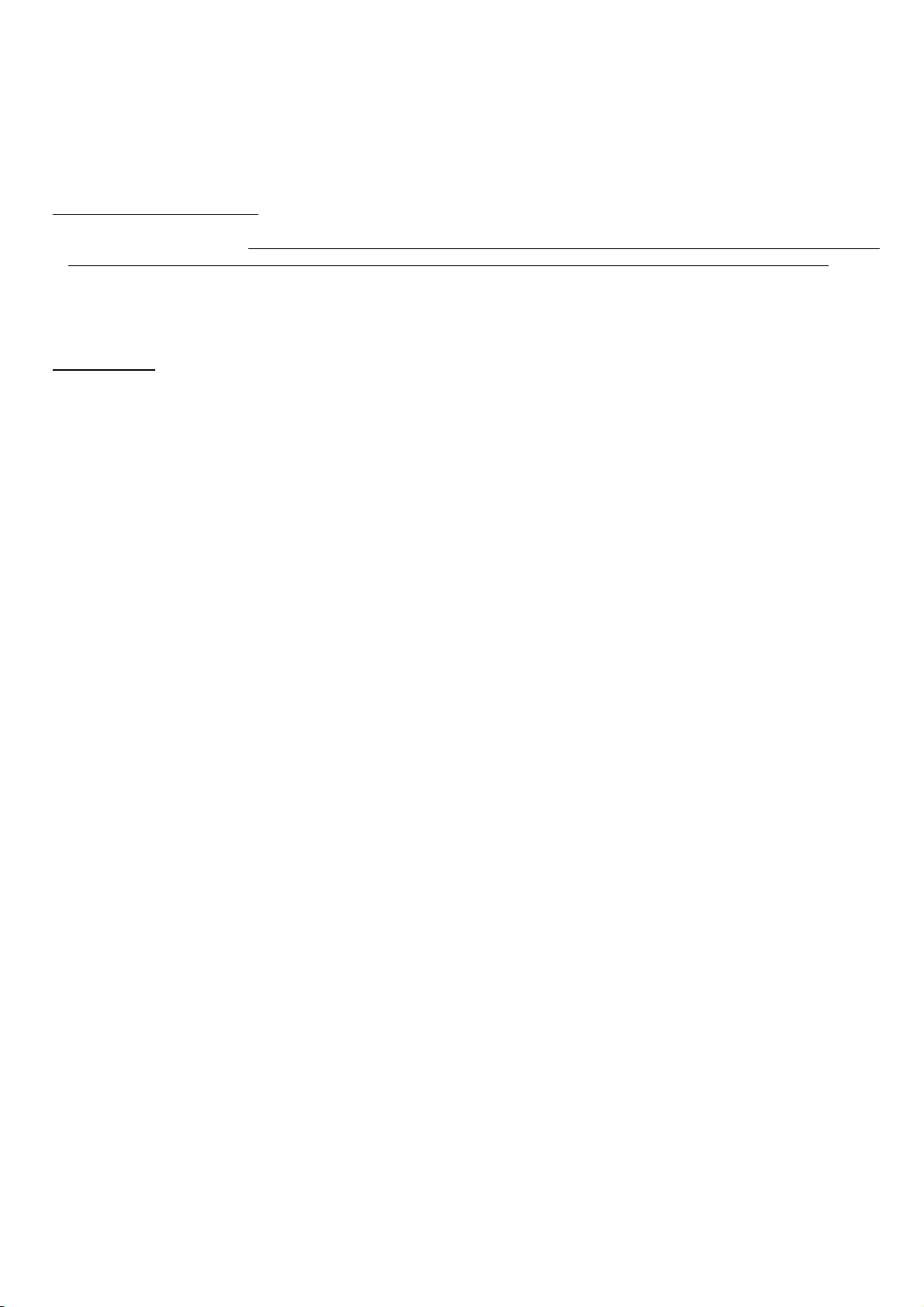

b) When removing the SPD main unit from the fixing base, pull out with vertical direction (④part) while tilting

the SPD main unit towards to the direction of arrow head ③, holding the both grab side of the SPD main unit.

Removing method of SPD main unit

and fixing base

Main unit

Fixing base

DIN rail

Slider

①Position the

fixing base on

DIN rail

②Push the

fixing base

into DIN rail

①Pull the slider

Slider Screw driver

②Pull off

①① ②

③

④