Ottobock | 6

2. Application

2.1 Intended Use

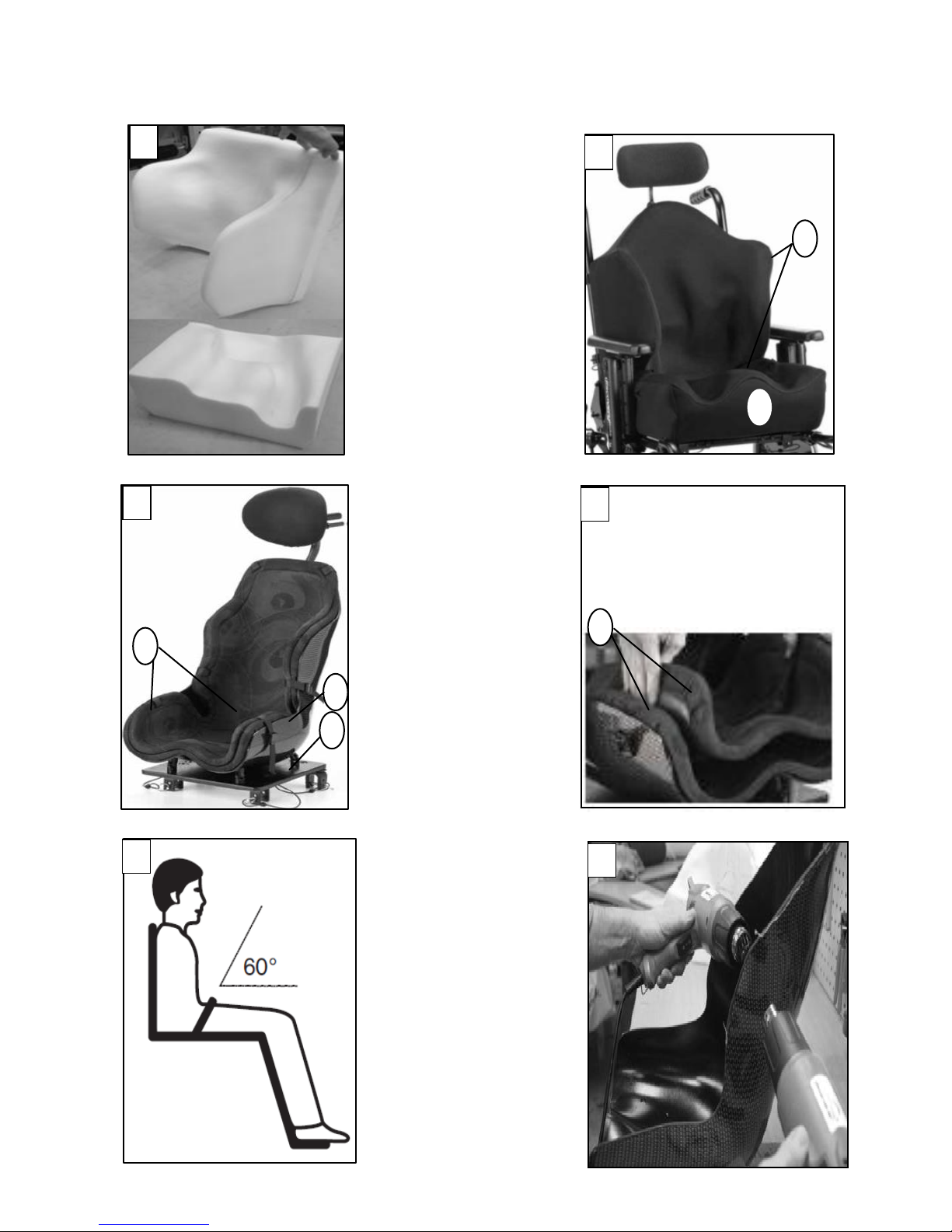

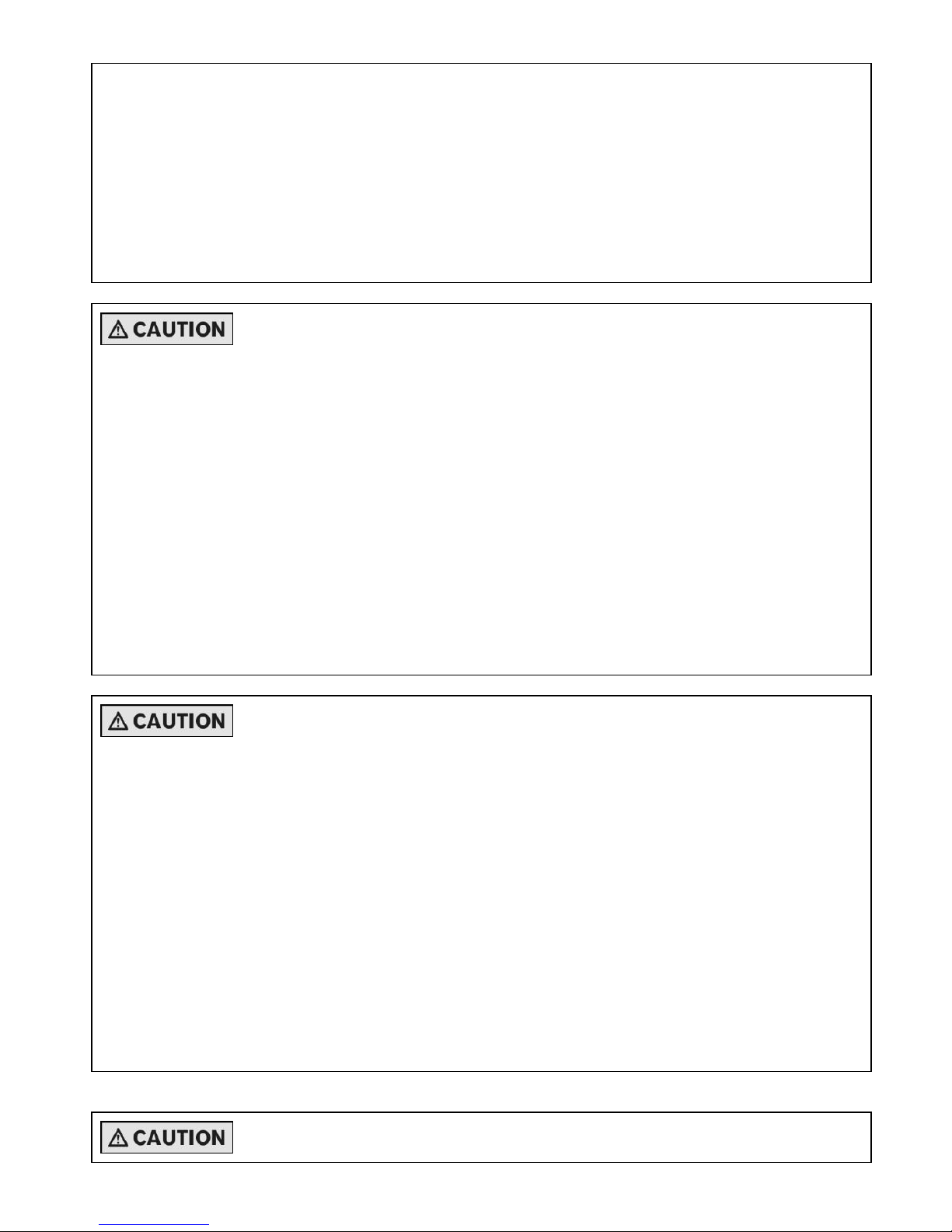

Custom made seats are contoured to a specific user’s form and, as such, are intended to be

used by a single individual with asymmetric postural and pressure care needs. The seats are

suitable for moderate to complex positioning needs and preventing pressure injuries in pa-

tients with paraplegia, hemiplegia, neurological deficits and rheumatic nerve and muscle

disorders.

Please note that the most appropriate wheelchair seating solution for an individual should

always be determined by a suitably qualified or experienced person based on a full risk

assessment and used in conjunction with a full program of care.

2.2 Area of Application

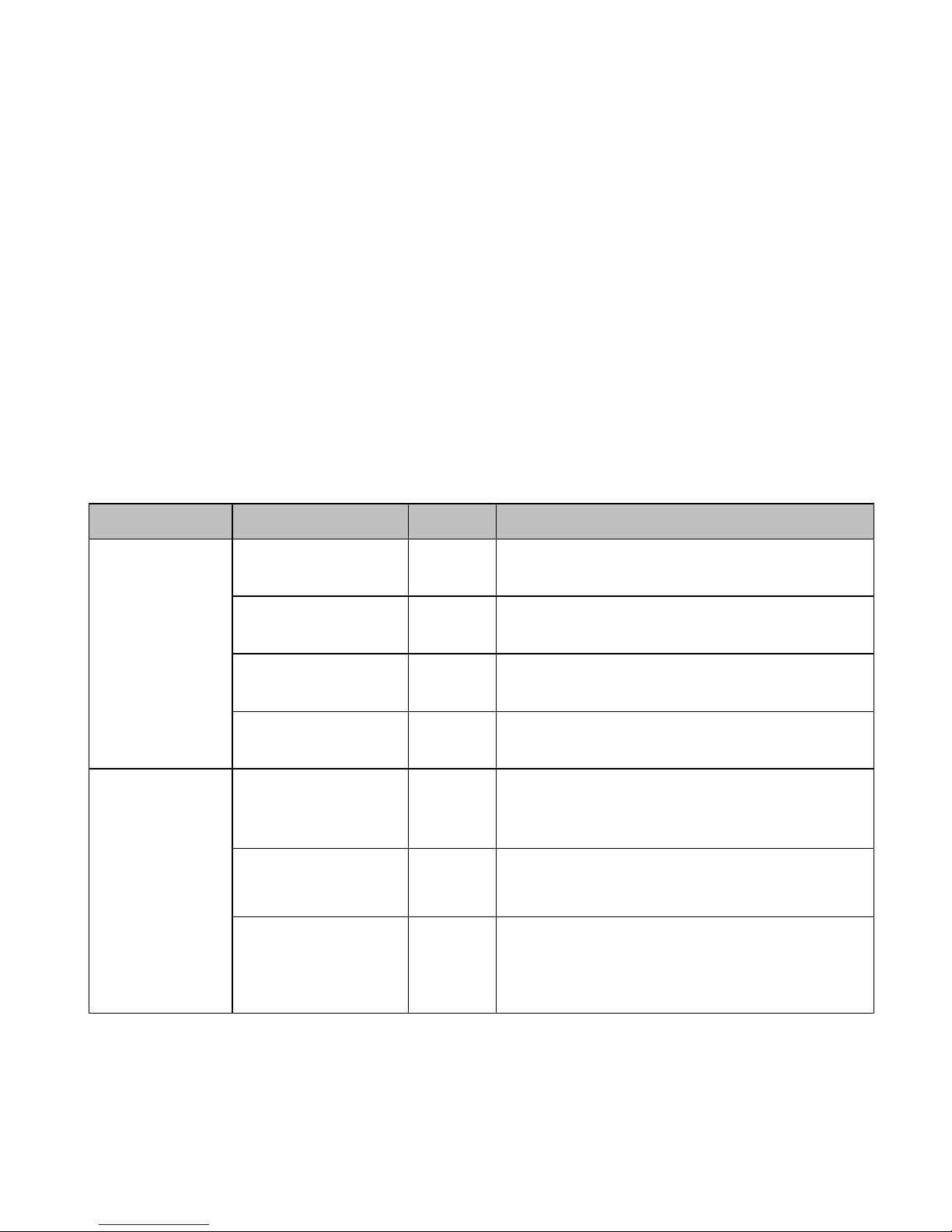

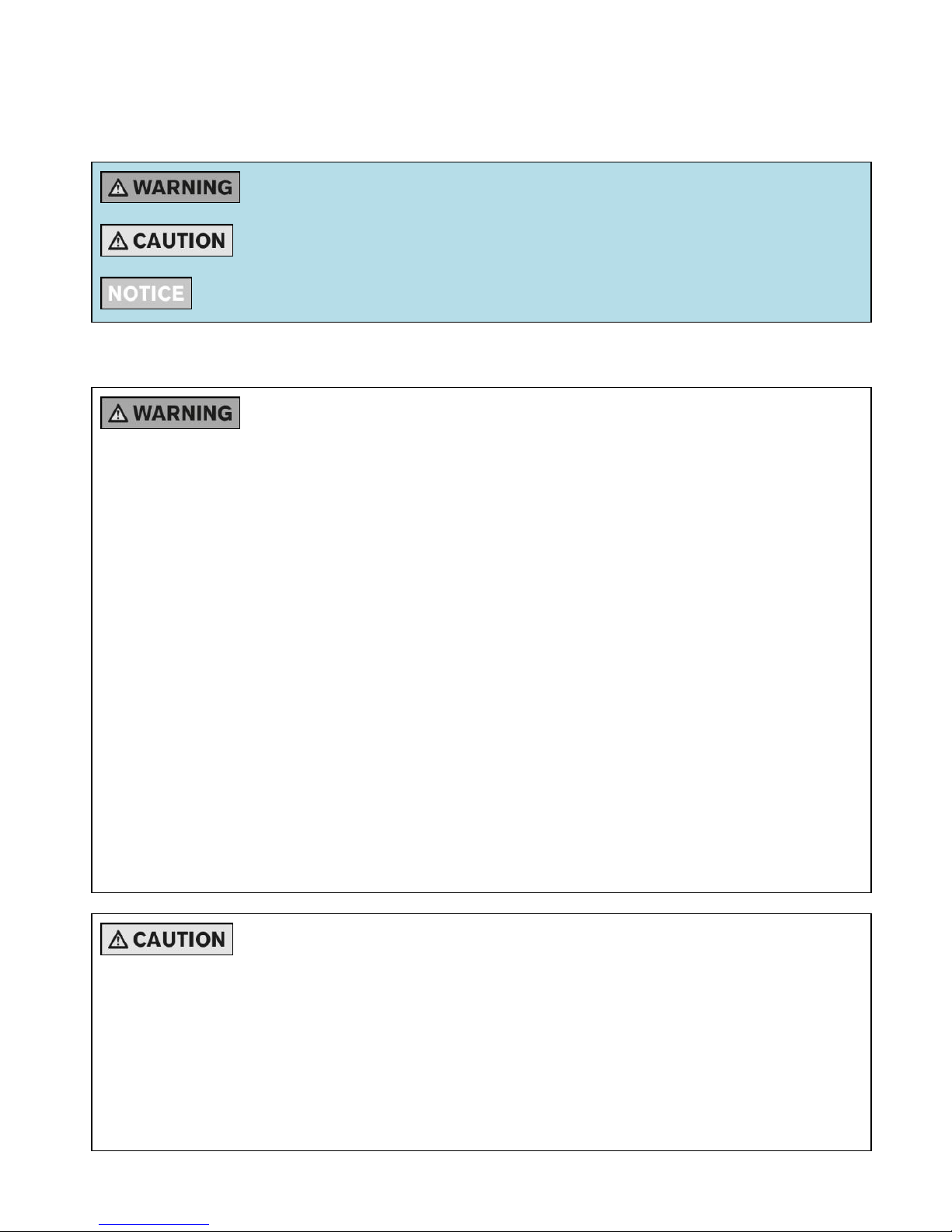

Because the seat is individually fabricated, it can be adapted for a wide range of users. The

order form includes options for additional reinforcements for users who are heavier or expe-

rience high tone or strong muscle spasms.

2.3 Contraindication

Seek professional advice before selecting an appropriate seating support where there

is an existing case or history of pressure injuries.

2.3.1 Absolute Contraindications

Not known.

2.3.2 Relative Contraindication

If redness of the skin or other problems occur during use, consult a doctor or therapist as

soon as possible.

2.4 Further Usage Restrictions

The product is designed for use by one person only. Re-use of the product is not permitted

due to hygiene considerations.

2.5 Qualification

This product may only be selected and adapted by trained qualified personnel.