E-025-2-E

3.7 Menu: Diag/Service (Checking and Adjustment) ...................................................................35

3.7.1 Self-diagnosis (Self diag) ............................................................................................... 36

3.7.1.1 Circuit Voltage Self-diagnosis (Circuit voltage) ........................................................ 36

3.7.1.2 Coil and Exciting Circuit Diagnosis (Exciting coil/circuit) ......................................... 37

3.7.1.3 Diagnosing Measurement Signal (Measurement signal).......................................... 38

3.7.1.4 Measurement Pipe Empty Detection Function (Empty pipe).................................... 39

3.7.2 Loop Test (Loop test)..................................................................................................... 40

3.7.2.1 Analog Output Loop Test (Fix Analog)..................................................................... 40

3.7.2.2 Pulse Output Loop Test (Fix Pulse) ........................................................................ 41

3.7.2.3 Status Output Loop Test (Fix Status output) ........................................................... 42

3.7.3 Analog Output Adjustment (Trim Analog) ......................................................................43

3.7.4 Cumulative Total Display and Control (Totalizer Control) .............................................46

3.7.5 Setting Accumulated Total Flow (Total flow set) ............................................................46

3.8 Menu: Maintenance (Maintenance) ....................................................................................... 47

3.8.1 Maintaining Transmitter (Maintenance xmtr) ................................................................ 48

3.8.1.1 Error Log Display (Error log) ...................................................................................48

3.8.1.2 Transmitter Internal Temperature Display (Xmtr temp) ............................................50

3.8.1.3 Displaying Operating Time (Operating time) ..........................................................50

3.8.2 Maintenance Test (Maintenance test) ..........................................................................50

3.8.3 Resetting Master (Master reset) .................................................................................. 51

3.9 Menu: Window (Window) ...................................................................................................... 53

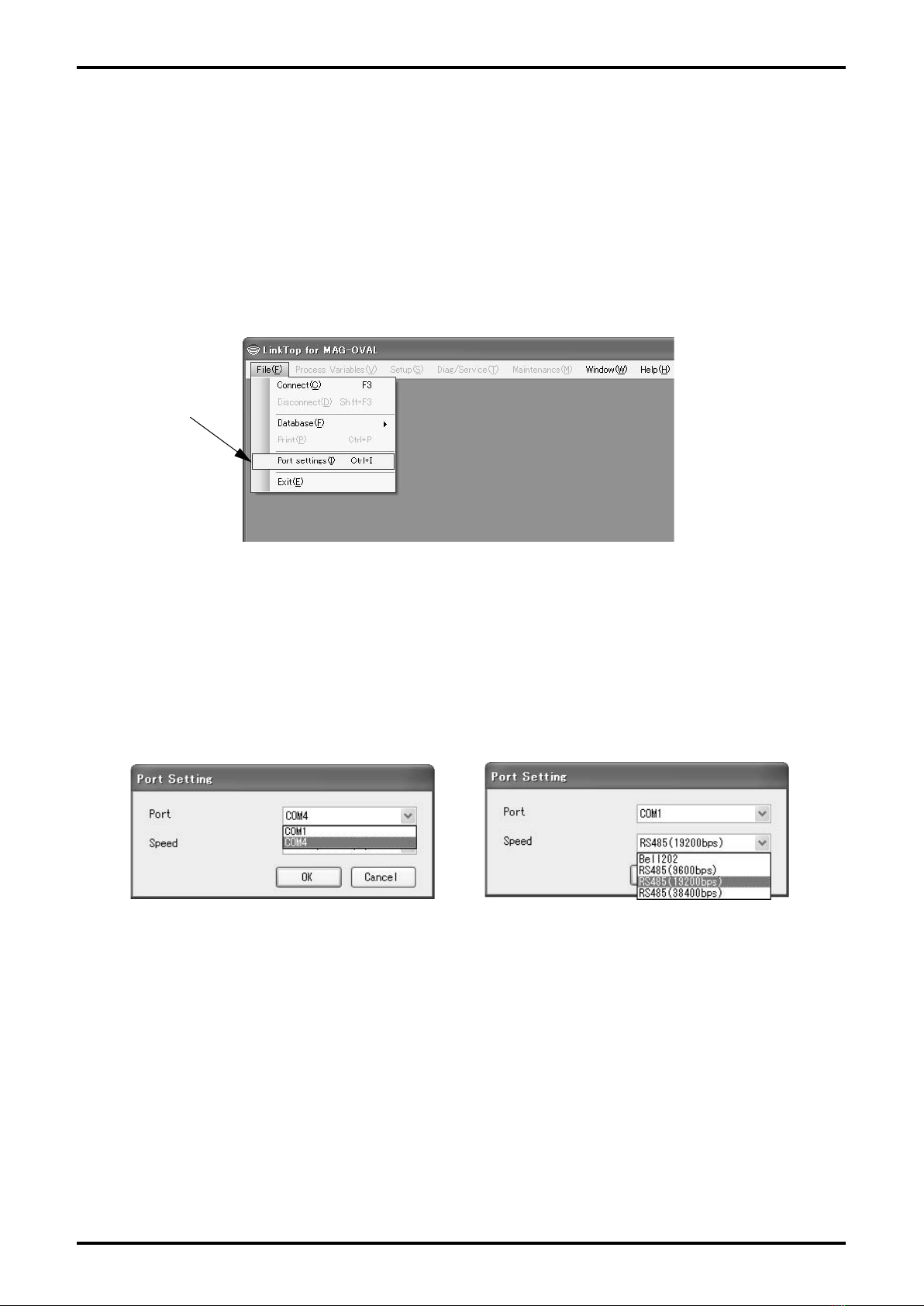

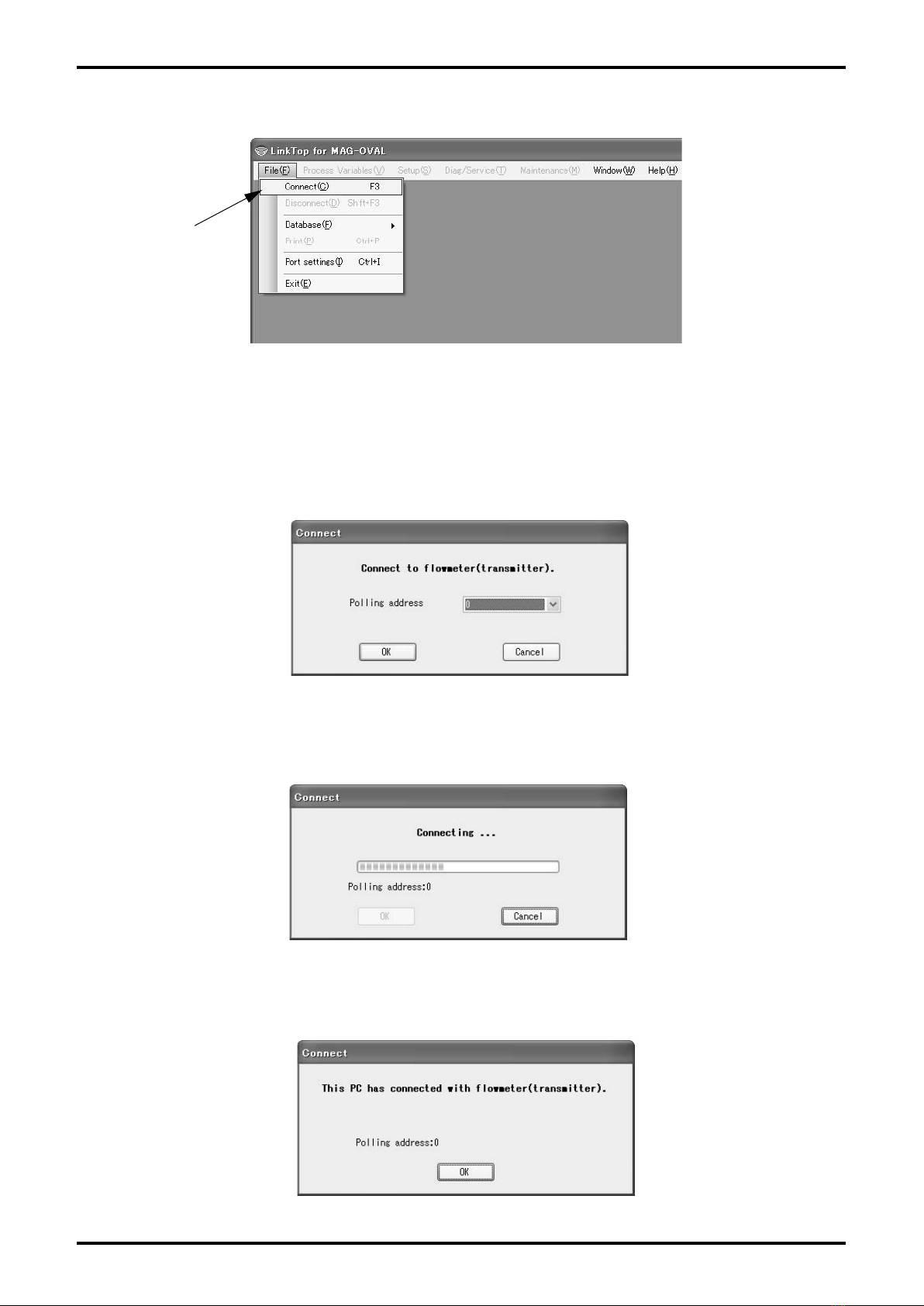

3.10 Menu: File (File) ................................................................................................................... 55

3.10.1 Database ..................................................................................................................... 55

3.10.1.1 Opening Files ......................................................................................................... 55

3.10.1.2 Saving Files ...........................................................................................................56

3.10.1.3 Deleting Files ......................................................................................................... 57

3.10.1.4 Downloading .......................................................................................................... 57

3.10.2 Printing ....................................................................................................................... 59

3.11 Troubleshooting.................................................................................................................... 62

3.11.1 If There is No Response ............................................................................................. 62

3.11.2 If It is Not Possible to Connect to the Flowmeter......................................................... 62

3.11.3 Input Errors.................................................................................................................. 62

3.11.4 Error/Alarm, Status List ...............................................................................................63

3.11.4.1 Error/Alarm ............................................................................................................63

3.11.4.2 Status ................................................................................................................... 65

4. PRODUCT CODE EXPLANATION .....................................................................................66

5. GENERAL SPECIFICATIONS ............................................................................................. 67