CONTENTS

1. SMART COMMUNICATION UNIT ............................................................................... 4

1.1 General .................................................................................................................................4

2. BEFORE YOU BEGIN................................................................................................... 4

2.1 Inspection upon Receipt ......................................................................................................4

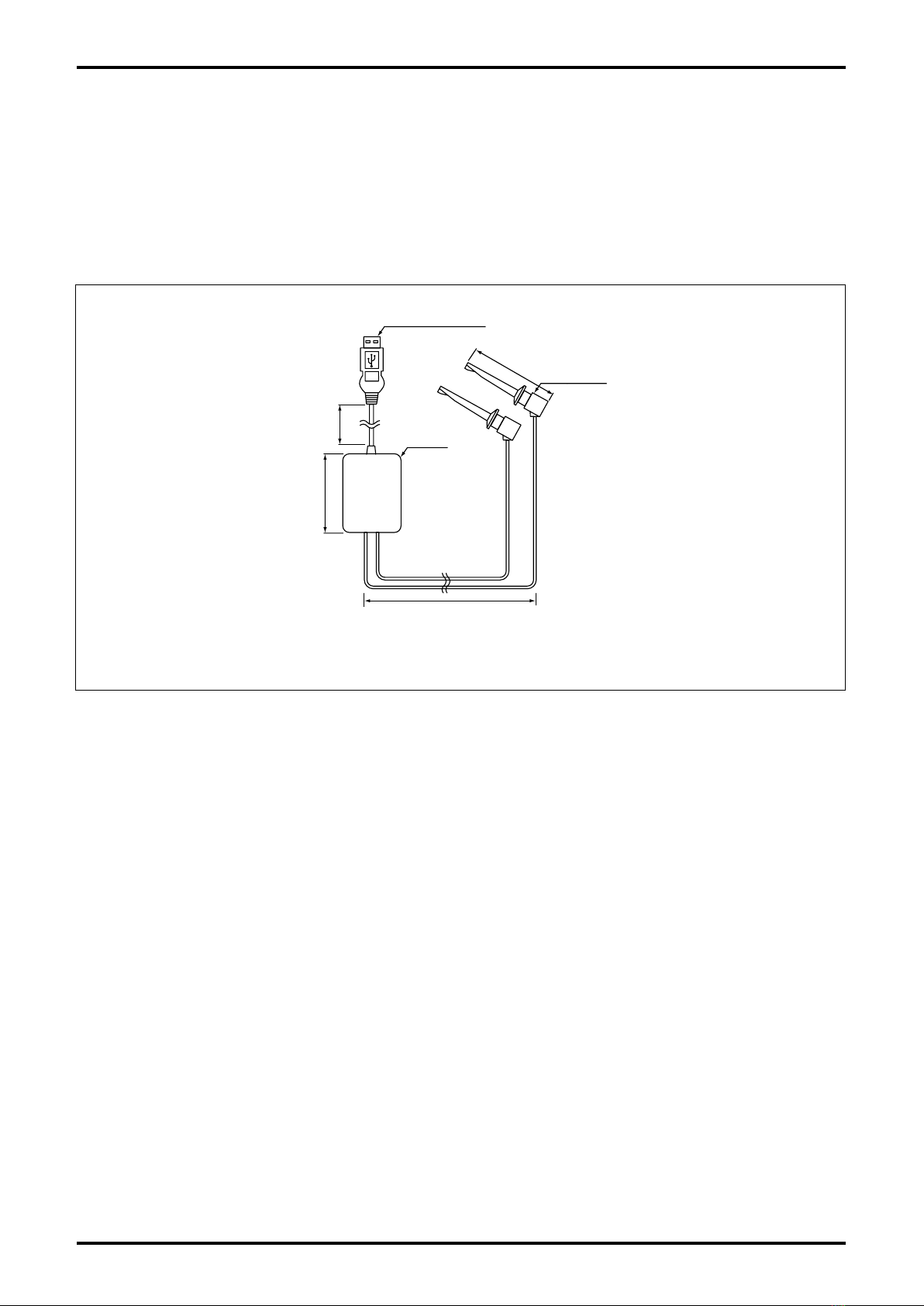

2.2 Hookup with Associated Equipment and Devices ...............................................................5

2.3 Communication Interface .....................................................................................................6

3. LinkTop OPERATION ................................................................................................... 7

3.1 LinkTop Screen.....................................................................................................................7

3.2 Starting LinkTop and Connections.......................................................................................8

3.2.1 Starting LinkTop ............................................................................................................................ 8

3.2.2 Port Setting ................................................................................................................................... 9

3.2.3 Connection.................................................................................................................................. 11

3.3 Terminating the Connection ...............................................................................................13

3.4 Terminating LinkTop ...........................................................................................................14

3.5 Menu: Process Variables (processing values display)........................................................15

3.5.1 View fld dev vars (processing values measurement) .................................................................. 16

3.5.2 Chart and Recording (chart display and logging) ....................................................................... 17

3.5.3 Write protect (write status display of transmitter) ....................................................................... 20

3.6 Menu: Setup (settings) .......................................................................................................21

3.6.1 Diameter inside (internal diameter of measuring tube) ............................................................... 22

3.6.2 Fld dev vars (transmitter variable)............................................................................................... 22

3.6.2.1 Flow (parameter setting related to flow rate) ........................................................................22

3.6.2.2 Fluid (parameter setting related to fluid) ............................................................................... 24

3.6.3 Outputs (output setting) .............................................................................................................. 26

3.6.3.1 Pulse output (pulse output setting) .......................................................................................26

3.6.3.2 Status output (status output setting) .................................................................................... 27

3.6.4 Device information (transmitter information setting) ................................................................... 29

3.7 Menu: Diag / Service (check / adjustment) ........................................................................31

3.7.1 Loop Test (loop test)....................................................................................................................32

3.7.1.1 Fix Analog (analog output loop test) ..................................................................................... 32

3.7.1.2 Fix Pulse (pulse output loop test).......................................................................................... 34

3.7.1.3 Fix Flow (simulated flow rate loop test) ................................................................................ 35

3.7.2 Calibration (transmitter's adjustment function)........................................................................... 37

3.7.2.1 Auto zero (auto zero point adjustment)................................................................................. 37

3.7.2.2 Init AGC (sensitivity adjustment) ........................................................................................... 39

3.7.3 Trim Analog (analog output adjustment) ..................................................................................... 41

3.7.4 Totalizer cntrl (cumulative total control) ...................................................................................... 44