NOTE:

The 10 A fuse-limit will be exceeded if tools with power

consumption of more than 1000 W is connected. Check the

fuse of your main power supply before connecting the tool.

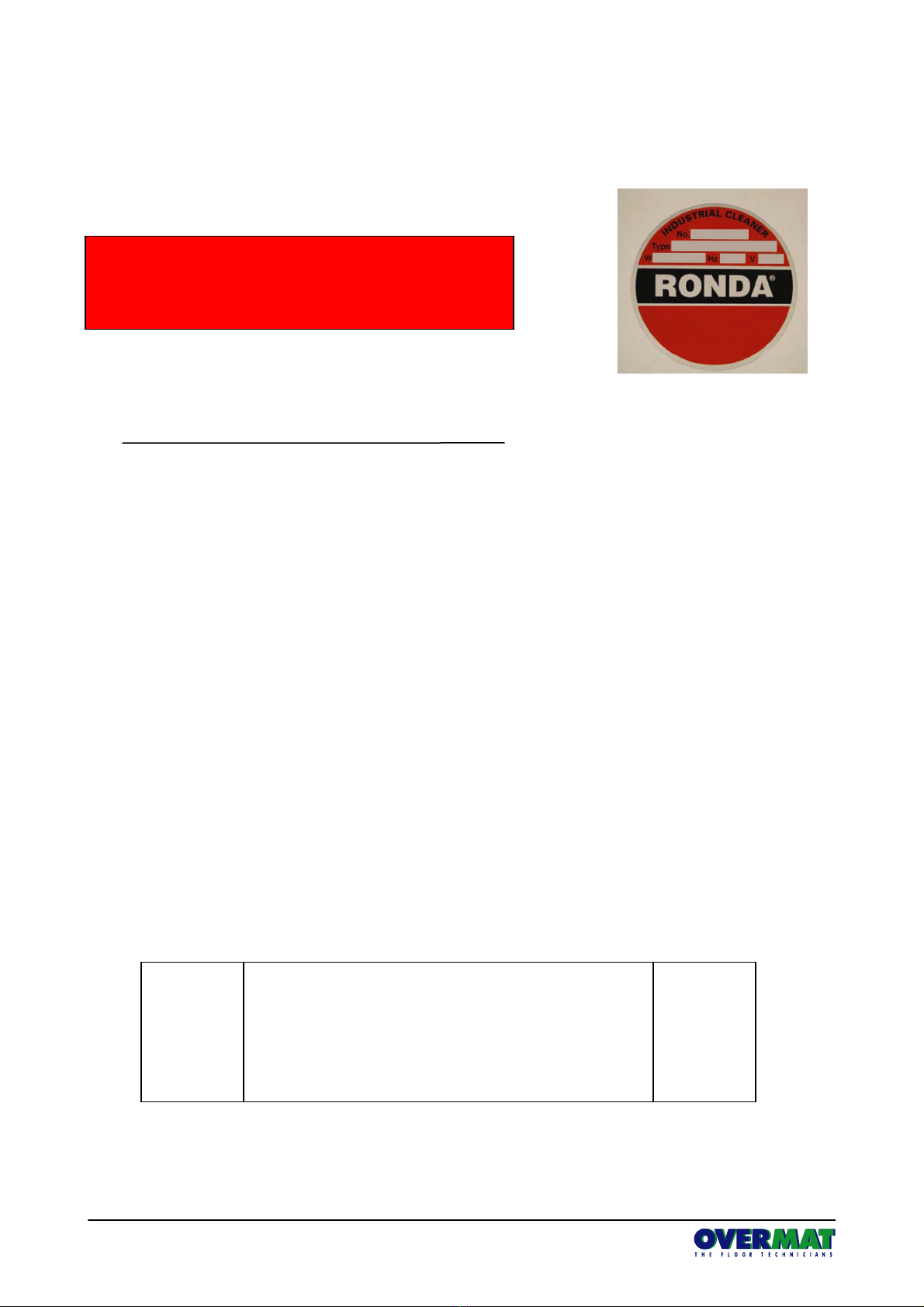

Collecting dry dust

When the appliance is correctly assembled it can be started on

the red switch on the motortop.

During operation RONDA 200 can be driven around on the five

pivotally wheels.

The floor nozzle is suitable for collecting dust from larger

horizontal areas. The nozzle is equipped with adjustable wheels

securing an optimal positioning of the nozzle on the floor.

Eventually the brushes will be

torn, reducing the efficiency of

the nozzle. Adjust the wheel-

height using the knob to

secure, that the brushes only

just touches the floor.

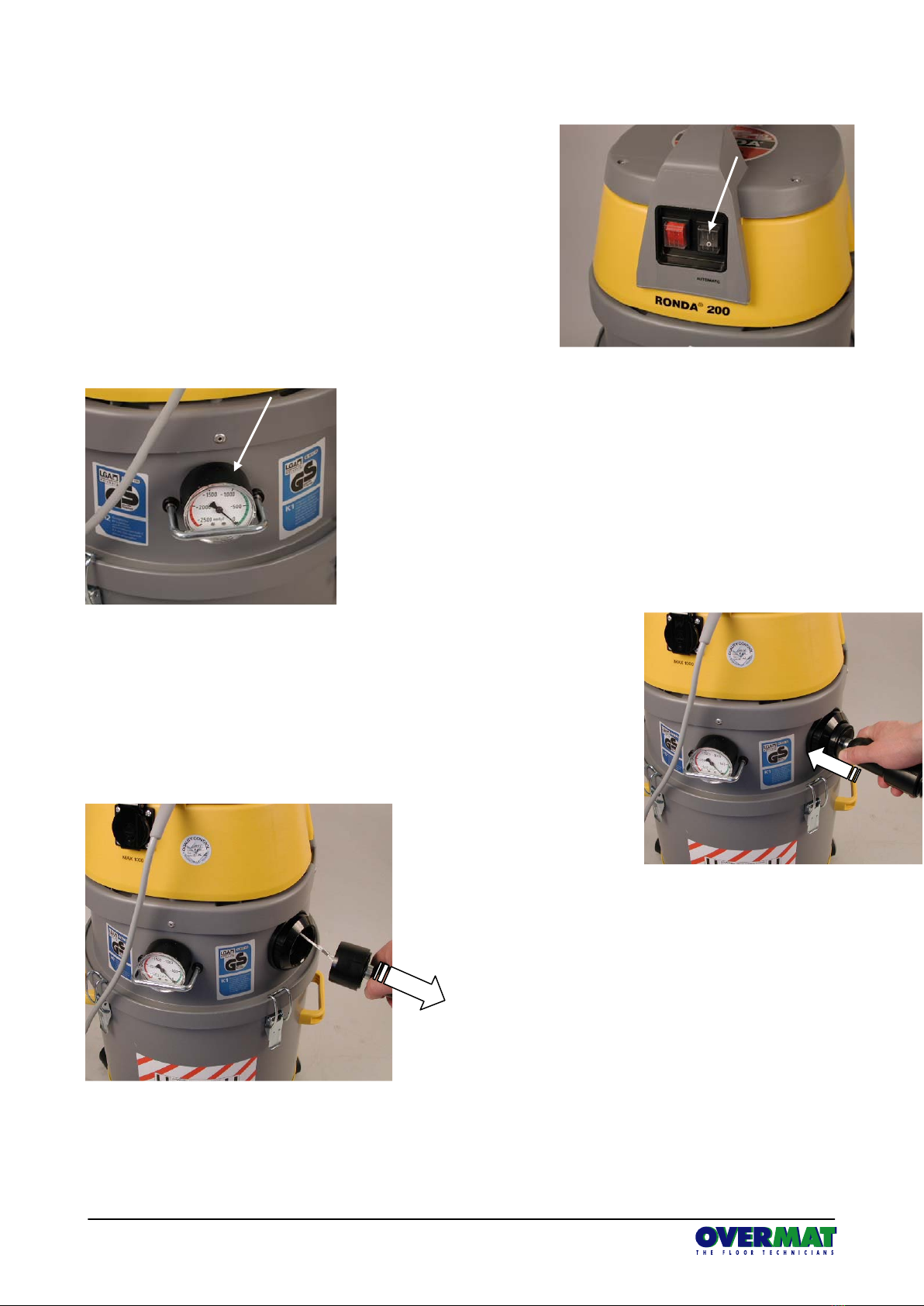

Power take-out and automatic start/stop

RONDA 200 is equipped with a power take-out socket with automatic start/stop. Connecting electrical hand-held

tools to the power take-out on the motortop, makes it possible to turn the RONDA 200 on and off with the on/off-

switch on the hand-held tool.

The power take-out is programmed to a delayed stop. After the

hand-held tool has been turned of, the RONDA 200 will

continue for a few seconds to ensure, that dust and particles in

the hose and pipe are led to the dust container.

The hand-held electrical tool is connected directly to the outlet

on the backside of the motortop.

It is possible to connect hand-held tool with a maximum power

consumption of 1800 W leading to a total current consumption

of app. 13 A.

9