MST Construction Manual –Issue 1 Page 2

CONTENTS

1Introduction..............................................................................................................................................................4

2Block Diagram..........................................................................................................................................................5

3Circuit Description .................................................................................................................................................6

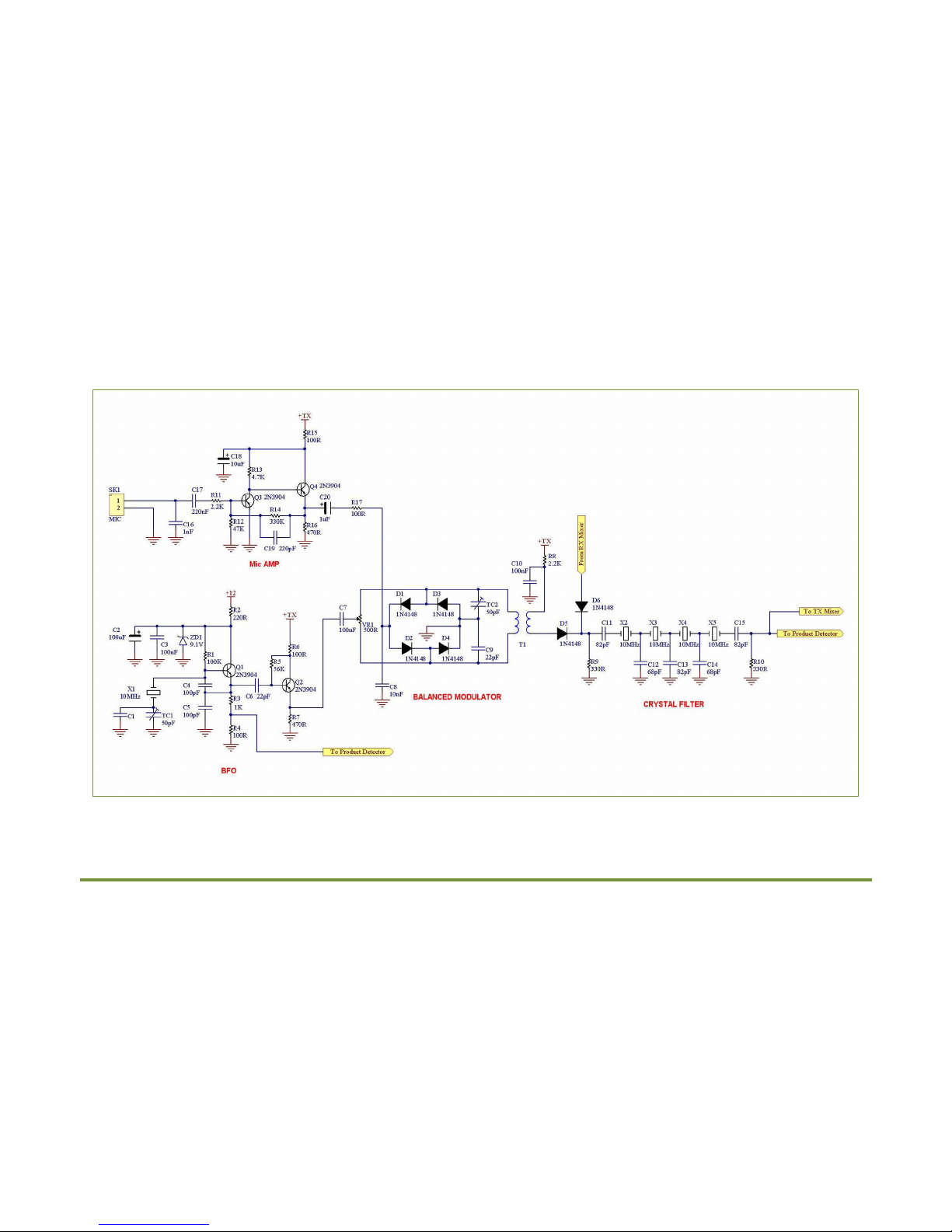

3.1 SSB generator..................................................................................................................................................6

3.2 Transmit mixer...............................................................................................................................................6

3.3 Power amplifier .............................................................................................................................................7

3.4 Receive mixer..................................................................................................................................................7

3.5 Receive audio..................................................................................................................................................8

4Parts List.................................................................................................................................................................. 14

4.1 Main Board Parts........................................................................................................................................ 14

4.2 Band Specific Parts .................................................................................................................................... 16

4.3 Off Board Parts............................................................................................................................................ 16

5Construction........................................................................................................................................................... 17

5.1 General............................................................................................................................................................ 17

5.2 Construction Steps..................................................................................................................................... 17

6Enclosure................................................................................................................................................................. 23

6.1 Rear Panel ..................................................................................................................................................... 23

6.2 Front Panel.................................................................................................................................................... 23

6.3 Mounting the PCB....................................................................................................................................... 23

6.4 Front panel label......................................................................................................................................... 24

6.5 Fitting the DDS VFO................................................................................................................................... 26

7Wiring up................................................................................................................................................................. 27

8Testing and alignment ....................................................................................................................................... 29

8.1 General............................................................................................................................................................ 29

8.2 Power on........................................................................................................................................................ 29

8.3 Receive............................................................................................................................................................ 30

8.4 Transmit......................................................................................................................................................... 30

8.5 Carrier frequency adjustment............................................................................................................... 32

9Operation................................................................................................................................................................. 33