Table of Contents

...............................................

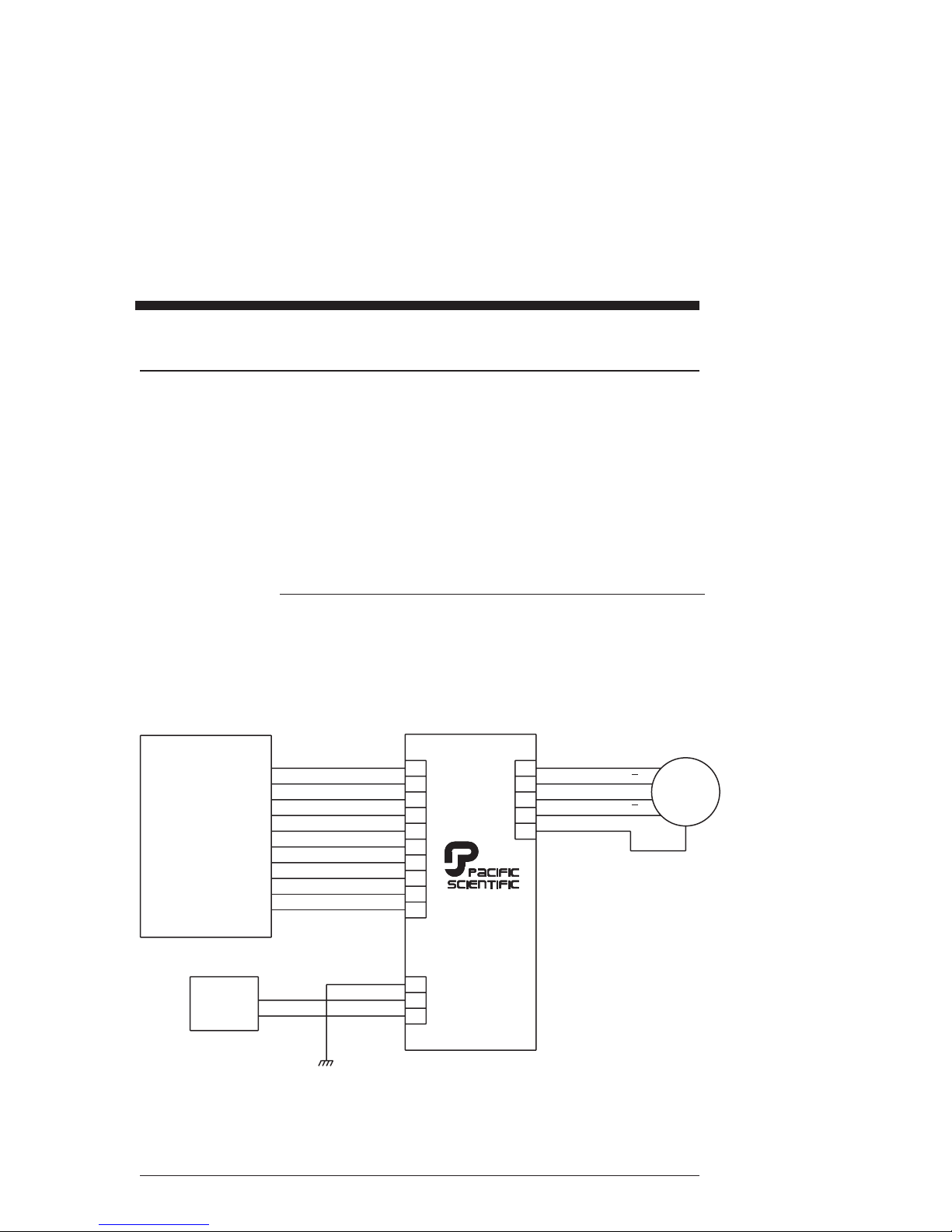

1 Overview of the 5630 Stepper Motor Drive 1 - 1

1.1 5630 Definition ···························1-1

1.2 Other System Components ·····················1-3

1.3 How to Use this Manual ······················1-4

2 Installing the 5630 Stepper Motor Drive 2 - 1

2.1 Unpacking and Inspecting the 5630 ·················2-1

2.2 Selecting Other System Components ················2-2

2.3 5630 Safety ·····························2-2

2.4 Mounting the 5630 in Your Installation···············2-4

2.5 Connecting the Three Input/Output Cables ·············2-6

2.5.1 J1 Motor Connection ........................2-8

2.5.2 J2 115 V ac Power Connection ..................2-14

2.5.3 J3 Signal Interface Connection ..................2-16

2.6 Setting Up Functions Using Switch SW1··············2-20

2.6.1 Step Set Up ............................2-21

2.6.2 Mid-Range Instability Control Set Up ..............2-22

2.6.3 Idle Current Reduction Set Up..................2-23

2.6.4 Current Set Up ..........................2-24

3 Powering Up the 5630 Stepper Motor Drive 3 - 1

3.1 Testing the Installation ·······················3-1

3.2 Troubleshooting ··························3-4

3.2.1 POWER LED Not On - 5630 Does Not Power Up .......3-5

3.2.2 ENABLED LED Not On - 5630 Does Not Recognize

Enable Input ............................3-7

3.2.3 STEP ACTIVE LED Not on or Motor Does not Step......3-8

3.2.4 POWER FAULT LED On - 5630 Contains Power Fault ....3-9

3.2.5 OVER TEMP LED On - 5630 Senses Excessive Temperature 3-10

Rev E 5630 Installation and Hardware Reference Manual