USING THE PHLANGER ^,^ ,,,,

Operation of Uie Phlanger controls is as follows:

FOWEB- When slid to the ri^t, QiiB switch will apply power to the circuit. The

LED below the swltdi should f^avr vbea power Is applied.

SPAN- This control determines the amount of low frequency OBclUator signal that

Is used to sweep tbe flanging effect. WUb Oie control at Tntn<mttm, vety little: swwp

oscillation occurs and the Center control has the most effect. As flie E^>an ctmtiol

Is Increased, liie sweeping effect will grow \dder both above and below the initial |-.-

eetting of;the Center control. At maximum, the Center control will be disabled and

the low frequency osplllator will be sweeping Hie flanging effect across it's eottre

.

range.

CENTER- This control can be thought of as a"manual" flanging control, or as an

initial delay lime adjustment. Both are correct. When the Span control is ai min-

imum, tho Center control becomes effective. With the Center control at minimum,

the initial delay time Is at maximum or about 10 milliseconds. This corresponds

to tbe flanging notches being at tlielr lowest frequency setting. As Uie Center control

is advanced, delay time Is decreased until, at maximum control setting. It is about

,6mtlUeeoonds,

ACCENT- The Accent control determines the gain of afeedback loop around the =

analog delay IC. This, like the "Q" control on active filters, causes aresonance '

to occur at afrequency wlioso period is equal to the time delay introduced by the

analog delay line IC. The resultant effect is an increased depth, or "hoUowness"

in tbe flanging effect,

MIX- Mixing oapabilitieB allow selecting only normal yi[^al, only the delayed signal,

or imy blend of the two. This allows for various depths of flanging effects, and gives

access to the straight delayed signal which can be used for many striking effects

which will he discussed later.

a'EED- Speed adjustment will vary the rate at which the flanging effect is automatically

B^pt when the Span control Is advanced. At minimum Speed setting, very slow sweep

rates sxe obtained (about one cycle every five seconds). As Oie control Is advanced,

the speed will increase to about one cycle per second.

The rear panel Jacks are to be used as follows:

INPUT -The signal source Is fed to tiie iiqut Jack. To avoid ncHilinearlties in (he

delay circuit, input level must be reBtxttit«lto?fS|ndtB peak-to-peak mutiDmin.<-'

This leaves plenty of headroom for m^mtm^Si^iiid line signals. '•'^ 9*t»'" <1

OUTPUT- Signals from &l6 Jack are fed to tiie snqillfier. Ou^jtot level will be

q)proximBtely equal to tiie original hiput level. '

.

,'-itUM^a mai' .-

CENTER- Remote voltage control of the initial delay time is possible with this

jack. When using the remote jack, the front panel Center control MUST be set

to maximum. Then, as asource of 0to 5volts is 3fifiUfi^;to the tip camecOaa

nf thu Jg^r-tf, gip dalay tjmp will pirf^ti tn maiHTTHim.

SPEED- As wlft the Center jack, Uiis jack allows remote voltage control of the

flanging sweep rate. Again, the voltage should be applied to the tip connection

of the Jack, but voltages as high as Dvolts can be used if desired. Maximum

effect will be derived from the remote jack if the front panel Speed control Is set

to minimum,however other setUngs of the ^eed control can be used If less range

Is deefxed.

CANCEL- This jack allows for use of afoot switch to eliminate the delayed portion

of the ou^nit si^uO. When the foot swltoh shorts the tip and shaft connections of

this Jack, the delayed signal will stop, and if the Mix control is set to less than

maximum, the normal signal will continue to pass.

The obvious use for aHanger is to duplicate the effect of tape reel flanging. This

"classic" sound is obtained when aBO/.'iO mix of normiil and delayed signal is used.

Accent should be set to mijiimum, ;uid nweep rate aivi Hpaji caii be s^ct n;i desired.

To achieve the more pronounced auuglng effect of Uio '70'b, the Accent control

can be advanced to the desired amount of depth.

IXiring the design process wf founrl Uial tJic addition of afew extra controls added

ahigh degree of versatUlly to the Phlongor, When tho unit is considered as a

general purpose time delay, many other eftoots can be obtahied v4ilob Initially

aren't as obvious, and can't bo accomplished with abasic flanger.

When the clock speed of tho Phlangor is changing, Ihe signal at the output of the

delay line erfiiblts asll^t pitch shift. If, for example, the clock speed is contin-

ually Increasing, the audio signal will be san^lod into Uie delay line at one rate

but will be sampled out at afoster rate. Thus, the Input frequency will be slillted

up by an amount dependent on the rate of increase of the clock frequency. Similarly,

when the clock rate is continually decreasing the Input signal will show adecrease

In frequency as it leaves the delay U&e, Using this phenomenom, we can generate

quite a few unusual cTTecte.

Periodic pltoh shifting Is known aa vibrato. With the Phlauger Mix control at

maximum (for 100% delayed signal) the Span control can be advanced to create

avibrato effect, Tbe sharp ewUoblng of the hitemal triangle wave m^ produce

too harsh an effect for some, but the Span control can be set to minimum, and an

external shie wave applied to tlio Ccnlcr j^-k. The PAIA 2720-.'5 Control Oscillator

synthesizer module is well suited lo ih::< appli cation. The external sine wave will

produce the familiar smooth vibrato uHu;dly associated with organs. Vibrato Isn't

aradical new effect, as most guitars, organs, and synthesizers have provisions

for this effect. But now you can have vibrato wherever you want it. Imagine vibrato

on a recording of agrand piano, achoir, or on chimes. Or If you are i;iaop»Ung

several instrumental tracks and later decide that there should have been vfbn& on

the saxophone, you can easily process the saxophone track through amodulated

delay line during mi»iown rather than rerecording the entire track.

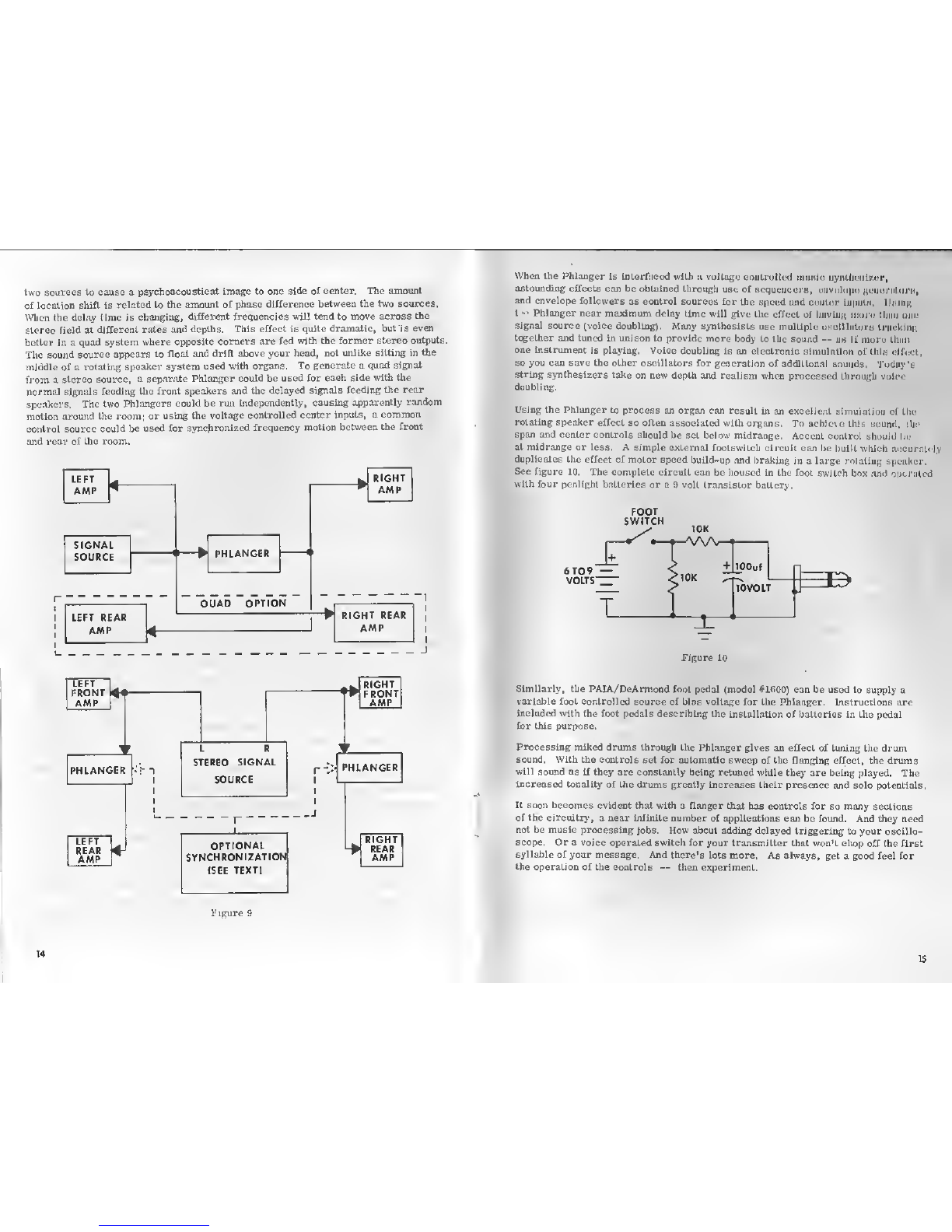

Another unique applicatton of the Phlanger is generation of stereo or quad motion

eSects from amono signal. See figure 9. For this effect, the original signal is

fed to Hie input of one amp AND to the Plilanger input. Tlie Phlanger output is then

fed to the remaining amp. Control settings on the Phlanger are the same as for

vibrato effects, except with aslov^r^ate. When asignal with complex harmonic

structure is fed flirmi^ this systCTO, some frefjoencies will be emitted from the

speakers In ^lase with each other. Ihe ai^iarent source of the sound will be between

the two speakers. Other frequencies will have enough phase dlKerence between the