1.5"Tapered Leg Tubing

M

Minimal with 1.0” diameter crossbars

LEG SYSTEM INSTALLATION INSTRUCTIONS

© 2018 Palmer Industries, Inc. Sinklegs.com 401-421-1730 3.

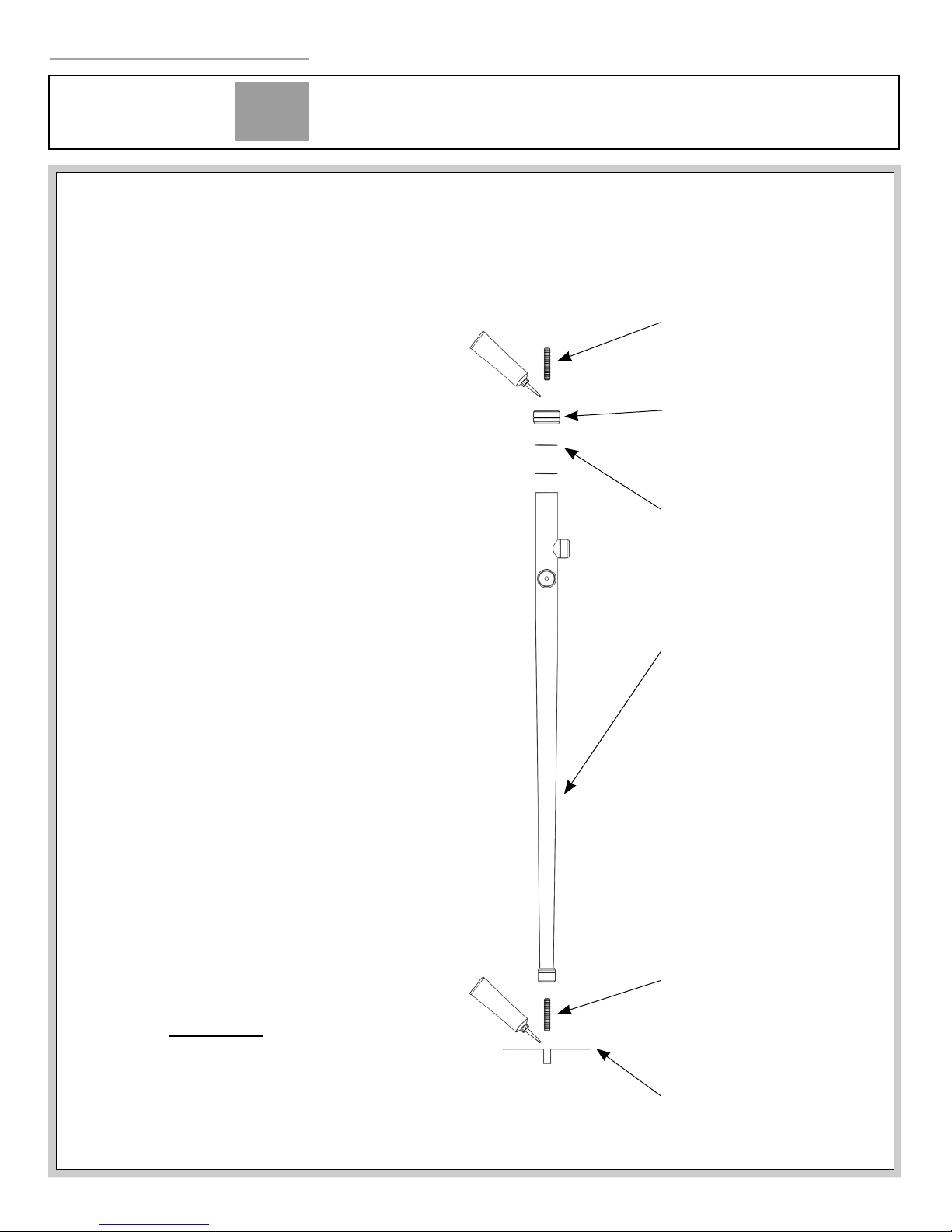

Counter Top Pin

Leg Assembly

Shims:

Add as needed to level

Top Cap

Floor

Floor Pins must engage

1/4”diameter holes

drilled into ooring.

Recommended minimum

hole depth of 1/4”

CUSTOM SINK LEG SOLUTIONS

PALMER

INDUSTRIES

rev: 091718

SEE ADDITIONAL PAGES FOR INSTRUCTIONS SPECIFIC TO INCLUDED OPTIONS.

• Determine that you have received the

correct product before unpacking and

unwrapping the leg system components.

• The leg system components must be

protected from abrasion and scratching

during installation. Use padding on the

oor to protect your console during

layout and assembly.

• The Minimal style may be eld cut to

reduce width and depth.

• Verticals must be plumb and horizontals

must be level. Wall Returns and Shelf

Supports must be parallel, and square

to the Horizontal Crossbar. Leg heights

may need to be shimmed to achieve a

level counter top.

• Leg assemblies must be positioned so

that the set screw holes face toward

the back wall and Wall Flanges must be

rotated so that the set screw holes are

not visible from a standing position in

front of the vanity.

• Wall bracket must be secured solidly to

the wall to bear the weight of the

counter top.

• Front Legs MUST be pinned to the oor

to prevent lateral movement.

• The counter top must be attached to

the tops of the legs and the wall bracket

with silicone adhesive. Conrm that the

installation is correct and complete and

that the shelf, if included, ts properly

before permanently gluing the counter

top into place.

INSTALLATION

INSTRUCTIONS

rev: 111918