MaintenancescheduleofHigh-Tro-Reelunit

Pleasecheckbythemaintenancetablebasedonthismaintenanceschedule.

Refertothemaintenancetableforaconcretecheckitem.

Atintroduction The5thyear The10thyear

Maintenancedonebytheelectricalworktrader.

The product-life is different in use conditions and the service space, however, It is possible to use it for about t 10 years

by regularly maintaining and the regular service in correct construction.

・Checkthepresenceofremarkabledirtofthesurfaceoftheconductor.

(Onceevery3to6months)→Cleanitwiththecottonwasteetc.

・ChecktheTro-Reelunitdoesn'tbecomeitinazigzagline.

(Onceevery3to6months)→Reviewthesizebetweenconductorsinthejoint.

・ChecktheTro-Reelunitisnotawayfromthehanger.

(Onceevery3to6months)→InstalltheTro-Reelunitonthehanger.

・

Checkwhetherthereisnot crackand alackoftheinsulationsheath

(Onceevery3to6months)

→ProductexchangerecommendationthatexchangestheTro-Reelunit.

High-Tro-Reel

・Checkwhetherthereislooseningofthefixationscrewortheterminalscrew.

(Onceevery3to6months)→Retighten.

・

Checkwhethertheresinhasnotbeendamaged.(Onceevery3to6months)

→Exchangeproducts.

Joiner

Centerfeed-injoiner

・

Checkwhetherthereislooseningofthenut.(Onceevery3to6months)→Retighten.

・

Checkwhethertheresinhasnotbeendamaged.(Onceevery3to6months)

→Exchangeproducts.

Hanger

Guidecap

Insulatingpiece

・

Checkwhetherthereislooseningofthebolt.(Onceevery1to3months)→Retighten.

・

Checkwhetherwearhasreachedthereplacementline.(Onceevery1to3months)

→Exchangethecollector,whenwornouttothereplacementline.

・

Checkdamageofspringpinandrotationaxis,wear-outofmetalfittingsofspringreceiving.

(Onceevery1to3months)→Exchangeproductswhendamageorabnormalityisfound.Pleasekeepnormal.

Collectorarm

Productexchange

recommendation.

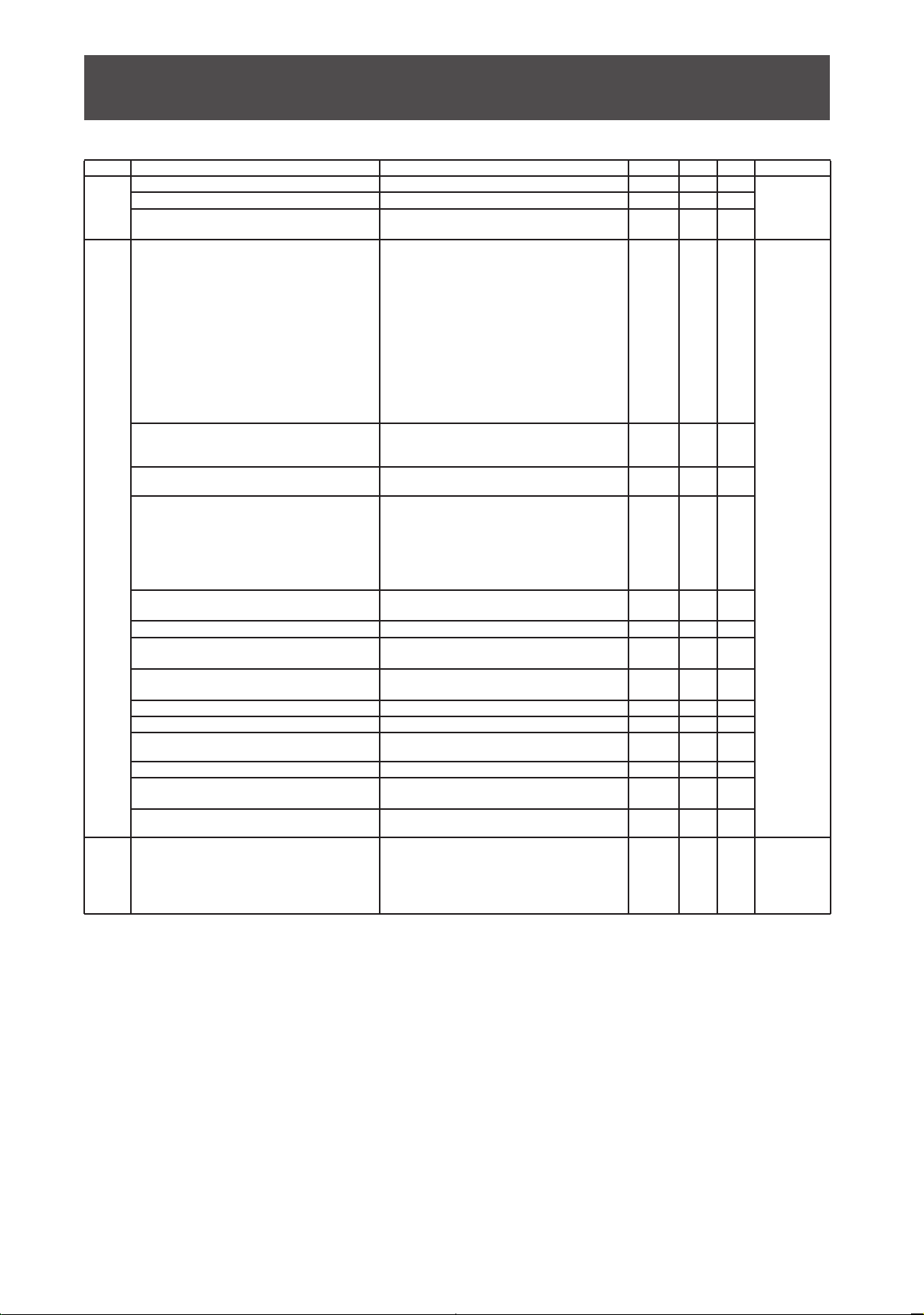

Trial run・Periodic inspection

Notes

・For using safely, please inspect the system one month after starting regular operation.

・The inspection cycle is mentioned below. However, determine your own inspection cycle

based on the actual operating rate and environmental condition.

Checktheamountofwearofthecollectorand

conductoroftheduct,replaceitifnecessary.

Don'ttheinsulatedsheathandtheresinpartofcollector

spinningshafttouch?

○

Retighten.

Isthereanyfixedscrewloosen?

○

Adjustitwithinspecifiedsize.

Arecorrectjoinermountingsize?

<Refertoinstallationmanual

>

・Orless·10℃:3003mm

·11℃˜40℃:3000mm

○

Adjusttheproperclearancesize.

・Adjustthelengthoftheduct,orAalignthejoiner.

・Adjustthemountingpositionofthehangers.

Arecorrectclearancesizeofbetweentheconductors?

<Refertoinstallationmanual

>

・Orless·10℃:5〜13mm

・11℃˜40℃:3〜10mm

Whendamageandcrackoccurredinthefixed

endinsulator,pleasechangeit.

Arenottherethecracksanddamagedona

plasticpart?

Ifitexceedsathresholdamountofwear,please

replacethemainconductorIncaseofwearing

downtothereplacementindicationlineatnext

inspection,pleasereplaceearlierthanusual.

Amountofwearoftheconductoriscorrect?

Amountofwearoftheconductor:0.5mmorless

○

Reviewforanydislocatedpositiononthe

unit.Correctifany.

Isnttheunitdislocatedfromthehanger?

<Refertoinstallationmanual

>

○

Correctthetwistingorbendingoftheduct.

※Ifyoucannotfix,replacetheduct.

Isthereasignificanttwistingorbendingoftheduct?

○

Adjustitwithinspecifiedsize.

・Adjustthelengthoftheduct,orAalignthejoiner.

・Adjustthemountingpositionofthehangers.

Whatisthemeanderoftheductorswellintheregulations?

<Refertoinstallationmanual

>

Theserpentinetolerance:standard±5mm

Toleranceofmodulation·:standard±3mm

○

Ifthetipofthesheaththicknessis1.2mm

orless,pleasereplaceinsulation

Istheredamageandcrackattheinsulating

sheath?

Removeanyprotrusion(convex)onthearc

scratchusingafile.

※Ifyoucannotfix,pleasereplacetheduct.

scratchusingafile.

Isthereanyarkgeneratedprotrusion

(convexshaped)onitsslidingsurface?

Cleanwithaspecificpurposecleaner

orwastecloth.

Checktoseeifthereisanyforeign

particlesadheringonitsslidingsurface

orifitisseriouslycontaminated.

Inspectioncycle(standard)

Measures

Result

※

RemedyContentsofinspection

Name

○:

Exchangerequired

Measures

●:

Finishedwithexchange

△:

Adjustmentrequired

▲:

Finishedwithadjustment

Result

○

:

Normal

×

:

Abnormali

y

Atitle Checkday YDM Thecheck

personincharge

・

Inspections item at the time of the pre-use test run(Checking at periodic inspection).

・

For using safely, please inspect the system one month after starting regular operation.

・The inspection cycle is mentioned below. However, determine your own

inspection cycle based on the actual operating rate and environmental

condition.

・Items in bold: Inspection items requiring particular attention.

Notes

<To Maintenance manager>

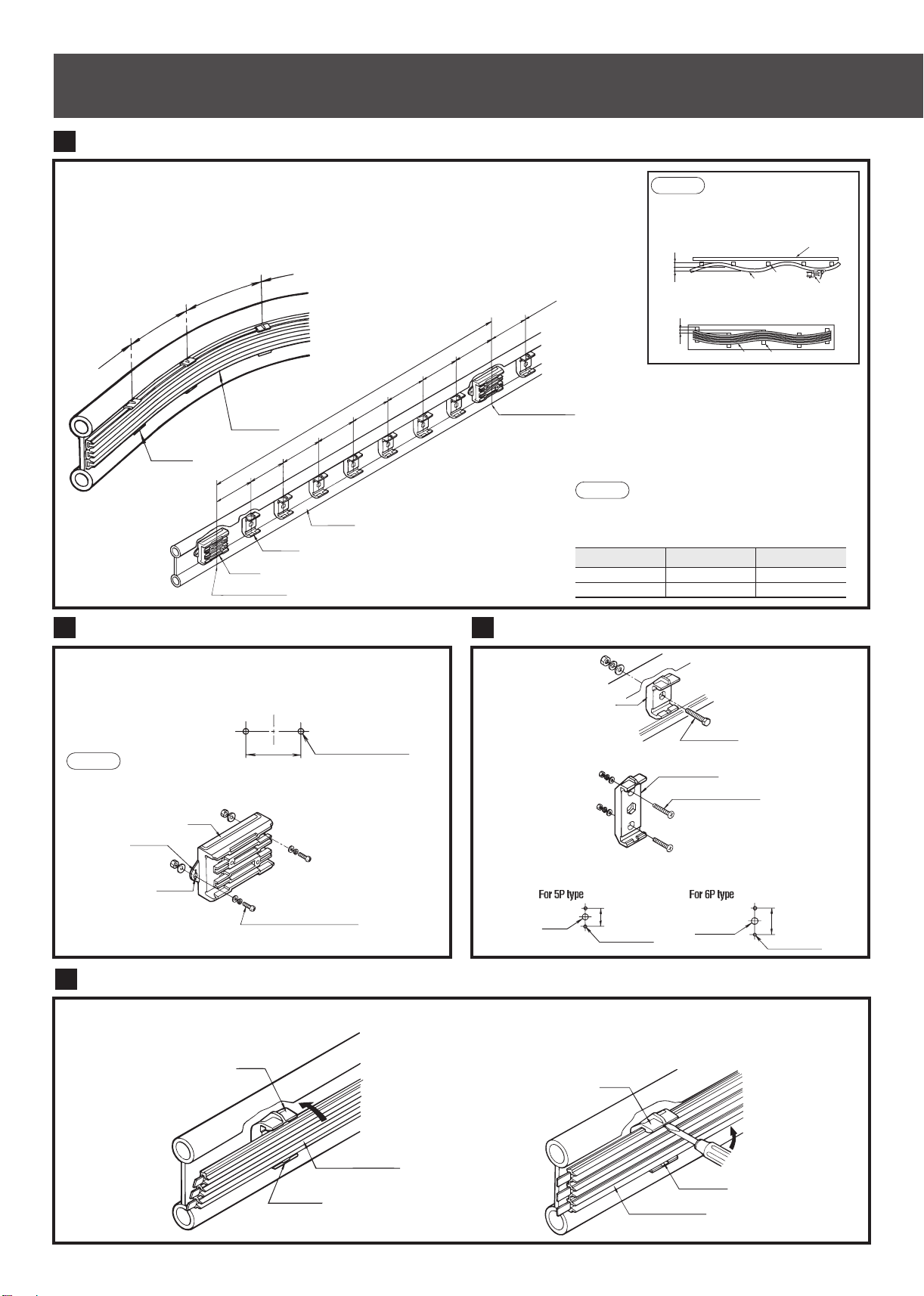

Tro-Reelunit

Joiner(Centerfeed-injoiner)

○

Retighten.Isthereanyfixedscrewloosen?

○

Adjustitwithinspecifieddimension.

Arecorrectclearancesizeofbetweentheguidecap?

<Refertoinstallationmanual

>

Isthegapbetweentheguidecapsizecorrect?

・Guidecapmutualclearance:10〜20mm

Horizontal:Max2mm

Vertical:Max2mm

Pleasehavetheaboverange,evenwhen

loadedtoratedloadonthetrolleyatanytime.

Guidecap

Pleaseexchange,whentheamountofwear

ofaguidecapresinpartis0.5mmormore.

Amountofwearoftheplasticiscorrect?

Amountofwearoftheplastic:0.5mmorless

Exchangeofaguideiswhentheconductorsliding

surfaceswillbecometallerthantheguide-capslidingsurfaces,

thenumberoftimesofpassageofthecollectoris5milliontimes

.

○

Whendamageandcrackoccurredinthefixedend

insulator,pleasechangeit.

Arenottherethecracksanddamagedon

aplasticpart?

○

Inserttheducttoensure.

Areinserttheconductorandsheathofaductcertainly?

<Refertoinstallationmanual

>

○

Adjustitwithinspecifiedsize.

Arecorrectcuttingsizeoftheductortheductend?

<Refertoinstallationmanual

>

•TheductcuttingSize:sizeofbetweenJoiner(L)-3mm

※ThesameisthecaseoftheCenterFeed-inJoiner.

・CuttingSizeoftheductend:Removetheinsulating

sheath27.5mmfromtheedgeoftheduct,

○

Retighten.Isthereanyfixedscrewloosen?

○

Adjusttotheproperpitch

Didyousetupthecorrectsizeandmountinghangers?

<Refertoinstallationmanual

>

・Straightsections:Max400mm

・Curvedsection :Max400mm

Joiner

(Centerfeed-injoiner)

Hanger

thenumberof

passesthrough

thecollector's

arm:1,000,000