3

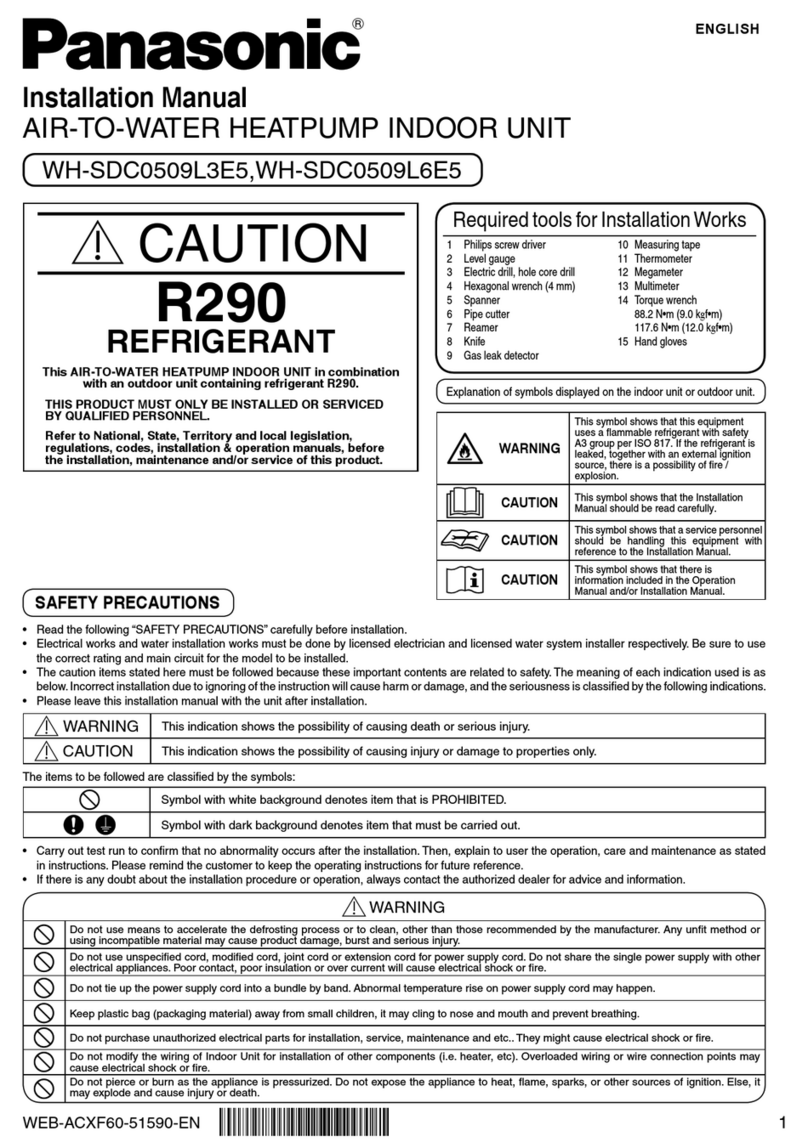

CAUTION

WARNING

WARNING

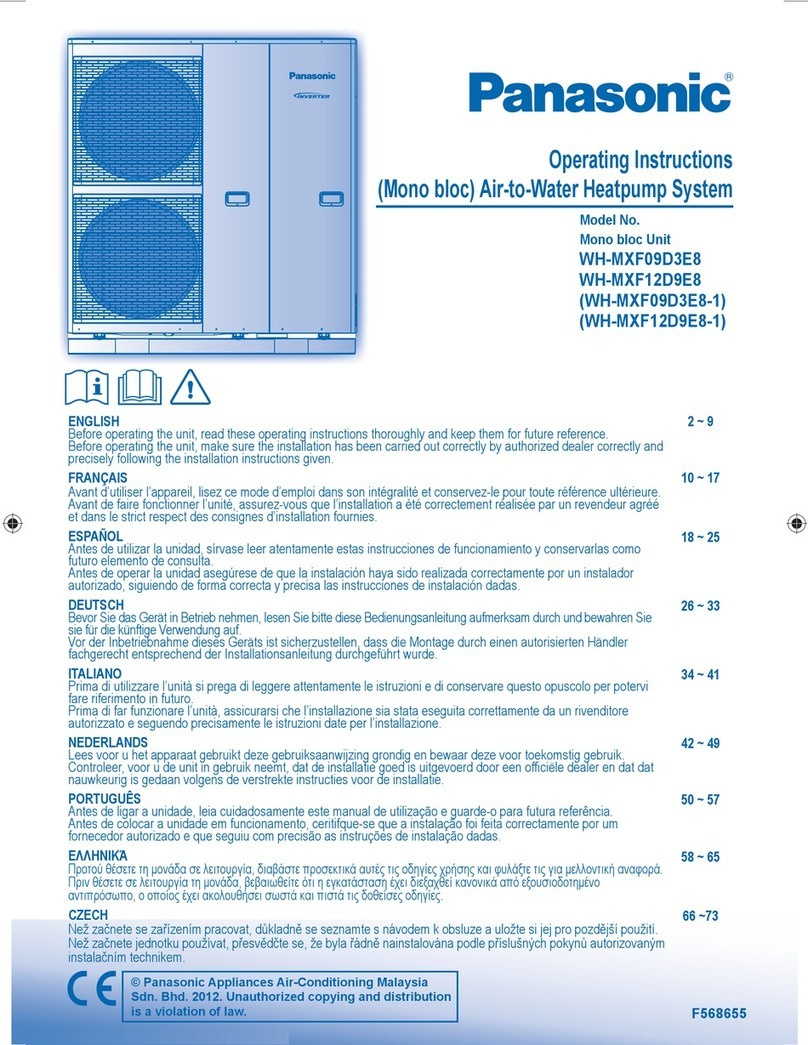

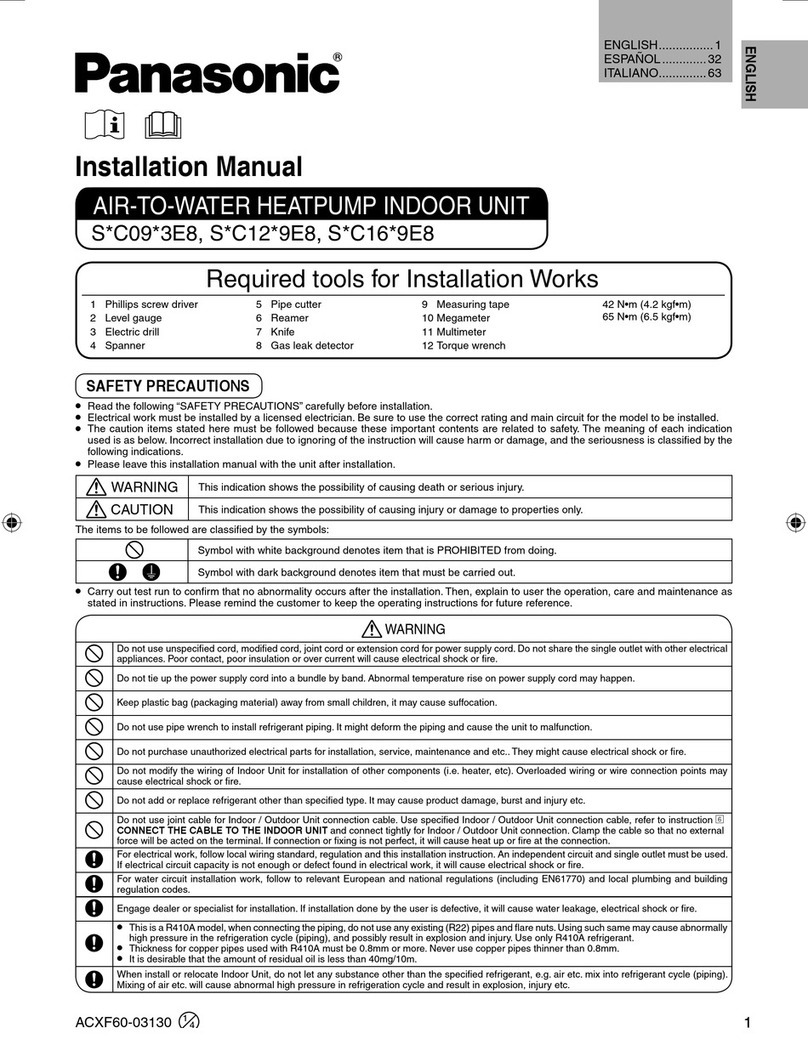

1. Safety Precautions

Read the following “SAFETY PRECAUTIONS” carefully before perform any servicing.

Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating and main

circuit for the model installed.

The caution items stated here must be followed because these important contents are related to safety. The

meaning of each indication used is as below. Incorrect installation or servicing due to ignoring of the instruction

will cause harm or damage, and the seriousness is classified by the following indications.

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to properties.

The items to be followed are classified by the symbols:

Carry out test run to confirm that no abnormality occurs after the servicing. Then, explain to user the operation,

care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for

future reference.

1. Do not modify the machine, part, material during repairing service.

2. If wiring unit is supplied as repairing part, do not repair or connect the wire even only partial wire break. Exchange the whole wiring unit.

3. Do not wrench the fasten terminal. Pull it out or insert it straightly.

4. Engage dealer or specialist for installation and servicing. If installation of servicing done by the user is defective, it will cause water leakage,

electrical shock or fire.

5. Install according to this installation instructions strictly. If installation is defective, it will cause water leakage, electric shock or fire.

6. Use the attached accessories parts and specified parts for installation and servicing. Otherwise, it will cause the set to fall, water leakage,

refrigerant leakage, fire or electrical shock.

7. Install at a strong and firm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly done,

the set will drop and cause injury.

8. Do not install outdoor unit near handrail of veranda. When installing outdoor unit at veranda of high rise building, child may climb up

to outdoor unit and cross over the handrail and causing accident.

9. For electrical work, follow the local national wiring standard, regulation and the installation instruction. An independent circuit and single outlet

must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

10. This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod and telephone.

Otherwise, it may cause electric shock in case equipment breakdown or insulation breakdown.

11. Do not use joint cable for indoor/outdoor connection cable. Use specified indoor/outdoor connection cable, refer to Installation Instructions

CONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor/outdoor connection. Clamp the cable so that no external force

will be acted on the terminal. If connection or fixing is not perfect, it will cause heat up or fire at the connection.

12. When install or relocate Air to Water Heatpump indoor/outdoor unit, do not let any substance other than the specified refrigerant, eg. air etc.

mix into refrigerant cycle (piping). Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

13. This is a R410A model, when connecting the piping, do not use any existing (R22) pipes and flare nuts. Using such same may cause

abnormally high pressure in the refrigeration cycle (piping), and possibly result in explosion and injury. Use only R410A refrigerant.

Thickness of copper pipes used with R410A must be more than 0.8 mm. Never use copper pipes thinner than 0.8 mm.

It is desirable that the amount of residual oil is less than 40 mg/10 m.

14. During installation, install the refrigerant piping properly before run the compressor. Operation of compressor without fixing refrigeration piping

and valves at opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

15. During pump down operation, stop the compressor before remove the refrigeration piping. Removal of refrigeration piping while compressor is

operating and valves are opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion,

injury etc.

16. After completion of the installation servicing confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant

contacts with fire.

17. Ventilate the room if there is refrigerant gas leakage during operation. Extinguish all fire sources if present. It may cause toxic gas when the

refrigerant contacts with fire.

18. Only use the supplied or specified installation parts, else, it may cause unit vibrate loose, water/refrigerant leakage, electrical shock or fire.

This symbol denotes item that is PROHIBITED from doing.