core

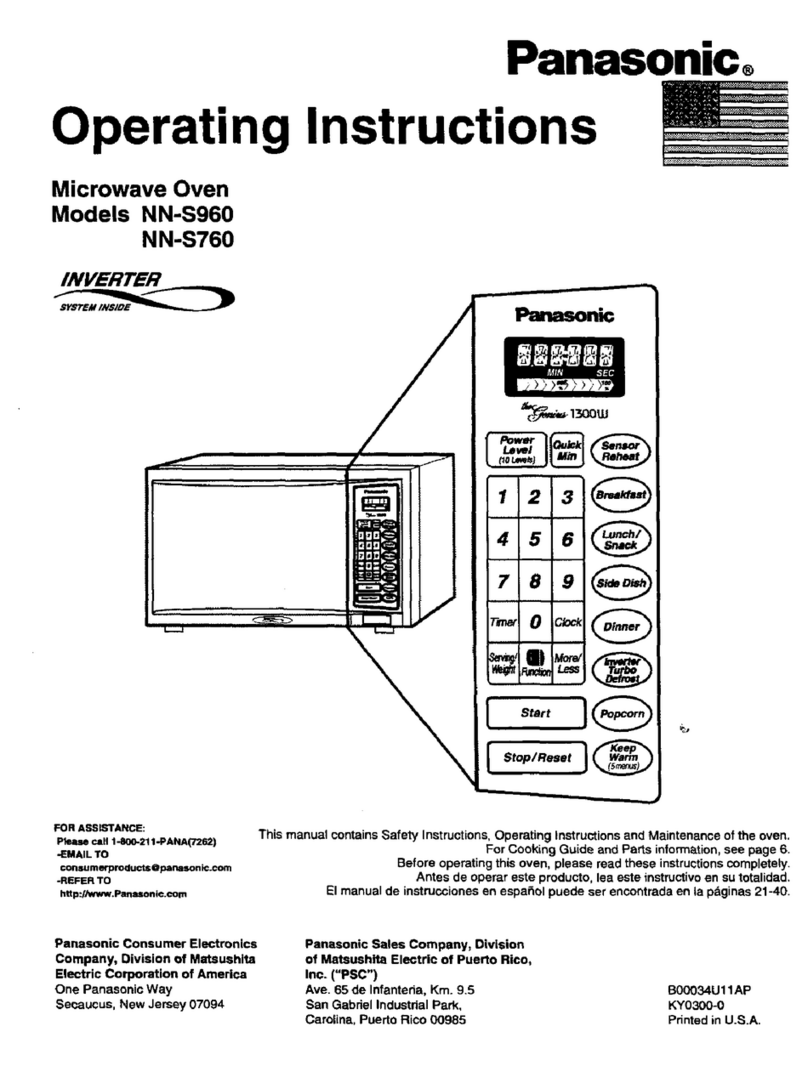

phat

NIN-8508,

NN-8558

NN-8808,

NN-8858

NN-8808P

This

service

manual

covers

products

for

following

markets.

When

troubleshooting

or

replacing

parts,

please

refer

to

the

country

identifications

shown

below

for

your

applicable

‘product

specification.

Me

For

U.S.A.

and

some

of

Latin

America

countries

--For

Canada

fe

Ap

;

WARNING

4.

This

product

should

be

serviced

only

by

trained

qualified

personnel.

2.

Though

this

product

has

been

manufactured

in

compliance

with:

“Federal

Performance

Standard

21

CFR

Subchapter

J”

(D.H.H.S.):

U.S.A.

models

or

“Radiation

Emitting

Devices

Act’

(NHW):

Canadian

models

it

is

very

important

all

repairs

should

be

made

in

accordance

with

procedures

described

in

this

manual

to

avoid

being

exposed

to

excessive

microwave

radiation.

;

3.

Check

for

radiation

leakage

after

every

servicing

according

to

the

“procedure

for

measuring

radiation

leakage”

on

page

24.

4.

Any

serviceman

who

learns

of

any

accident

pertaining

to

microwave

radiation

leakage

should

immediately

notify

the

appropriate

address

listed

below.

IN

U.S.A.

Matsushita

Services

Company

IN

PUERTO

RICO

PSC

(MSC)

50

Meadowland

Park

way,

(PSC)

Ave.

65

De

Infanteria,

KM

9.7

Secaucus,

New

Jersey

07094

Victoria

Industrial

Park

Attention:

Engineering

Support

Division.

Carolina,

Puerto

Rico

00630

(201)

348-7000

(809)

750-4300

IN

HAWAII

PHI

IN

CANADA

Matsushita

Electric

of

Canada

Limited

(PHI)

99-859

Iwaiwa

Street

(MELCA)

5770

Ambler

Drive,

Mississauga,

P.O.

Box 774

Honolulu,

Hawaii

96808-0774

Ontario,

L4W2T3

(808)

488-7779

(416)

624-5010

5.

There

are

special

components

used

in

the

microwave

oven

which

are

important

for

safety.

These

parts

are

marked

with

a

ZX

on

the

replacement

parts

list.

It

is

essential

that

these

critical

parts

should

be

replaced

with

manufacturer's

specified

parts

to

prevent

microwave

leakage,

shock,

fire,

or

other

hazards.

Do

not

modify

the

original

design.

PRECAUTIONS

TO

BE

OBSERVED

BEFORE

AND

DURING

SERVICING

TO

AVOID

POSSIBLE

EXPOSURE

TO

EXCESSIVE

MICROWAVE

ENERGY

(A)

Do

not

operate

or

allow

the

oven

to

be

operated

compartments,

check

the

magnetron,

waveguide

with

the

door

open.

or

transmission

line,

and

cavity

for

proper

align-

(B)

Make

the

following

safety

checks

on

all

ovens

to

ment,

integrity

and

connections.

ors

be

serviced

before

activating

the

magnetron

or

(D)

Any

defective

or

misadjusted

components

in

the

in-

other

microwave

source,

and

make

repairs

as

terlock,

monitor,

door

seal,

and

microwave

genera-

necessary:

:

tion

and

transmission

systems

shall

be

repaired,

re-

(1)

Interlock

operation

placed,

or

adjusted

by

procedures

described

in

(2)

Proper

door

closing

this

manual

before

the

oven

is

released

to

the

(3)

Seal

and

sealing

surfaces

(arcing,

wear,

and

owner.

other

damage)

(E)

A

microwave

leakage

check

to

verify

compliance

(4)

Damage

to

or

loosening

of

hinges

and

latches.

with

the

Federal

Performance

Standard

should

be

(5)

Evidence

of

dropping

or

abuse

performed

on

each

oven

prior

to

release

to

the

(C)

Before

turning

on

microwave

power

for

any

service

owner.

test

or

inspection

within

the

microwave

generating

CONTENTS

PRECAUTIONS

TO

BE

OBSERVED

BEFORE

AND

DURING

K

FACTORS

AND

POWER

LEVELS

vv

esstesssresetsreeieeeteisereees

mae

SERVICING

TO

AVOID

POSSIBLE

EXPOSURE

TO

CAUTIONS

TO

BE

OBSERVED

WHEN

TROUBLESHOOTING:-**-"+----

15

EXCESSIVE

MICROWAVE

ENERGY

*i-0s-rsescssstercsrestesreseeeteecenenecs

2

DISASSEMBLY

AND

PARTS

REPLACEMENT

PROCEDURE:***--"-""*

16

FEATURE

CHART

&

LOCATION

OF

NAMEPLATE

*eerrrerrcesrteeseteeeeses

3

COMPONENT

TEST

PROCEDURE

crertrtrctetetreetecteceee

seer

eer

ne

neenees

94

FEATURE

DIAGRAM

&

CONTROL

PANEL

«rrsrstrrrrrrrtttettrrerrrereere

4

MEASUREMENTS

AND

ADJUSTMENTS

sccceccerccesccsceteeesetteeen

esse

ee

23

OPERATION

PROCEDURE

--0-+0+-+--+sessesrseeseeestereerseesetesttstceseerenaees

5

PROCEDURE

FOR

MEASURING

MICROWAVE

ENERGY

LEAKAGE

--

24

ACCESSORIES

&

COOKING

UTENSILS

bane

e

eee

nee

eer

e

teen

nee

neta

eeassesenneas

6

TROUBLESHOOTING

GUIDE

errr

errr

eter

ret

teeter

reer

errr

r

ere

eee

eer

SCHEMATIC

DIAGRAM

(FOR

U.S.A.

MODELS)

<0

-r0ser0rcerereeeerees

7

DIGITAL

PROGRAMMER

CIRCUIT-TEST

PROCEDURE

vy

SCHEMATIC

DIAGRAM

(FOR

CANADIAN

MODELS)

aed

t

ee ee

arn

eneeecrneres

8

EXPLODED

VIEW

AND

PARTS

LIST

seer

santes

once

enter

vee

sacreesonen

ee

yes

SCHEMATIC

DIAGRAM

(NN-8808P):*+-020-200

sce

ceretsertereeseetetereeteees

9

DIGITAL

PROGRAMMER

CIRCUIT

PARTS

LIST:--

seen

DESCRIPTION

OF

OPERATING

SEQUENCE

Peeve

eereee

er

rete

rere

ree

ere

eee

10

AUTO

SENSOR

EXPLANATION,

gee)

~2-