Panasonic PT-302 User manual

Other Panasonic Projector manuals

Panasonic

Panasonic PT-L711E User manual

Panasonic

Panasonic PT-LM1E User manual

Panasonic

Panasonic PT-LC55E User manual

Panasonic

Panasonic PT-MZ880 User manual

Panasonic

Panasonic PTAX200U - LCD PROJECTOR User manual

Panasonic

Panasonic PT-LB78V Installation guide

Panasonic

Panasonic PT-AE900U User manual

Panasonic

Panasonic PT-LB51E User manual

Panasonic

Panasonic PT-VX400 User manual

Panasonic

Panasonic PT-56WX51KR User manual

Panasonic

Panasonic PT-LX321 User manual

Panasonic

Panasonic PT-F200 Series User manual

Panasonic

Panasonic PT-DZ12000 User manual

Panasonic

Panasonic PT-F300NTE Installation and maintenance instructions

Panasonic

Panasonic PT-D7700E User manual

Panasonic

Panasonic PT-AX200 User manual

Panasonic

Panasonic PT-DZ16KE User manual

Panasonic

Panasonic PT-DW740E User manual

Panasonic

Panasonic PT-47WX49 User manual

Panasonic

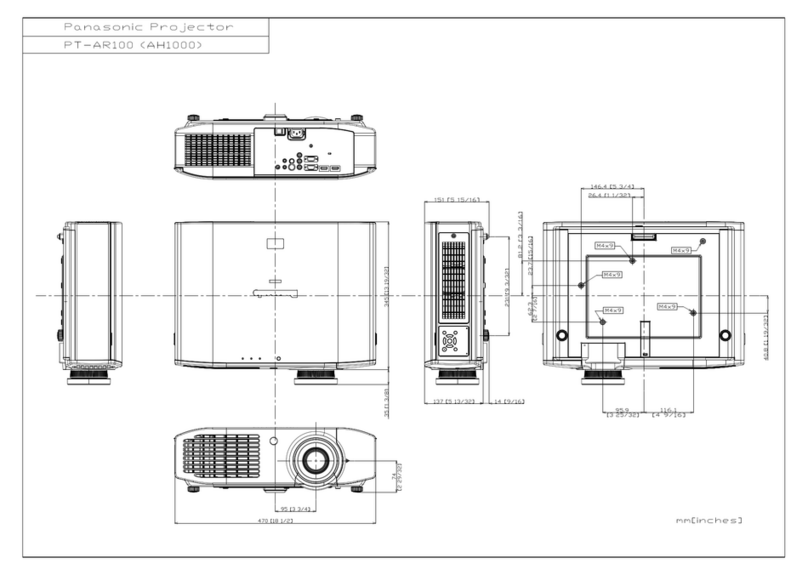

Panasonic PT-AR100 Guide