Panasonic Corporation 2014©

Panasonic Corporation Automation Controls Business Division

industrial.panasonic.com/ac/e/

Relay Soldering and Cleaning Guidelines

–2– ASCTB45E 201402-T

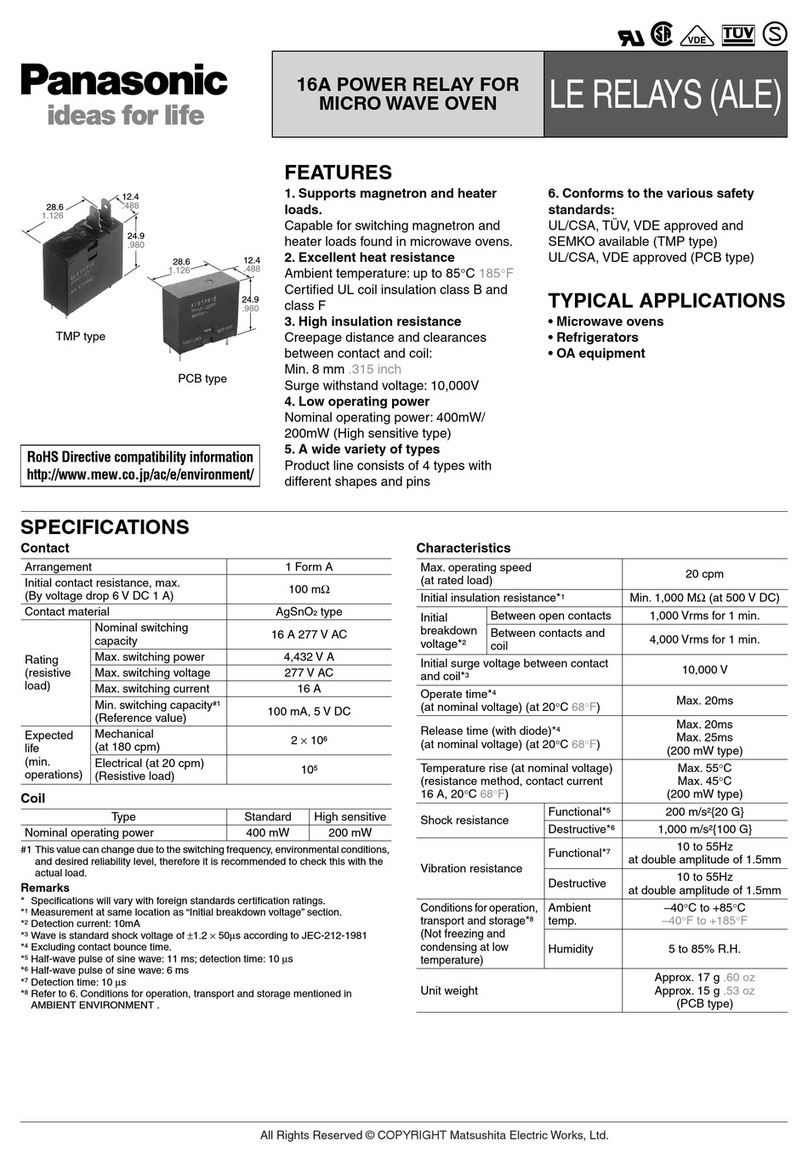

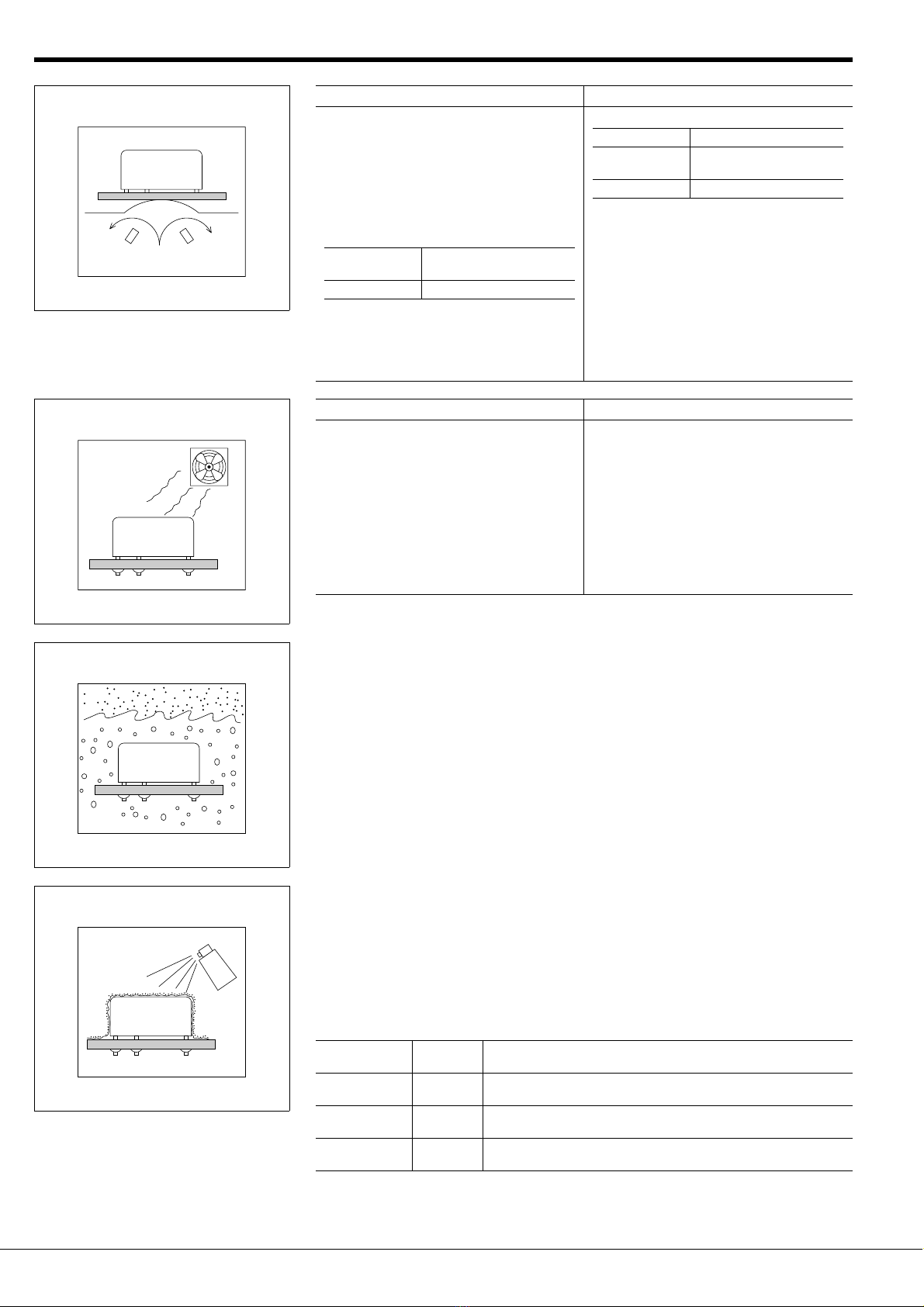

4. SOLDERING Automatic Soldering Hand Soldering

• Flow solder is the optimum method for

soldering.

• Adjust the level of solder so that it does

not overflow onto the top of the PC

board.

• Unless otherwise specified, solder

under the following conditions

depending on the type of relay.

• Please take caution with multi-layer

boards. Relay performance may

degrade due to the high thermal

capacity of these boards.

Solder

Temperature 260°C±5°C 500°F±41°F

Soldering Time Within approx. 6 seconds

• Keep the tip of the soldering iron clean.

Soldering Iron 30W to 60W

Iron Tip

Temperature 350°C 662°F

Soldering Time Within approx. 3 seconds

5. COOLING Automatic Soldering Hand Soldering

• Immediate air cooling is recommend to

prevent deterioration of the relay and

surrounding parts due of soldering heat.

• Although the environmentally sealed

type relay (plastic sealed type, etc.) can

be cleaned, avoid immersing the relay

into cold liquid (such as cleaning

solvent) immediately after soldering.

Doing so may deteriorate the sealing

performance.

—

6. CLEANING

• Do not clean dust-cover type relays and

flux-resistant type relays by immersion.

Even if only the bottom surface of the PC

board is cleaned (e.g. with a brush),

careless cleaning may cause cleaning

solvent to penetrate the relay.

• Plastic sealed type relays can be

cleaned by immersion. Use a Freon- or

alcohol-based cleaning solvent. Use of

other cleaning solvents (e.g. Trichlene,

chloroethene, thinner, benzyl alcohol,

gasoline) may damage the relay case.

• Cleaning with the boiling method is

recommended. Avoid ultrasonic cleaning

on relays. Use of ultrasonic cleaning may

cause breaks in the coil or slight sticking

of the contacts due to the ultrasonic

energy.

• Do not cut the terminals. When

terminals are cut, breaking of coil wire

and slight sticking of the contacts may

occur due to vibration of the cutter.

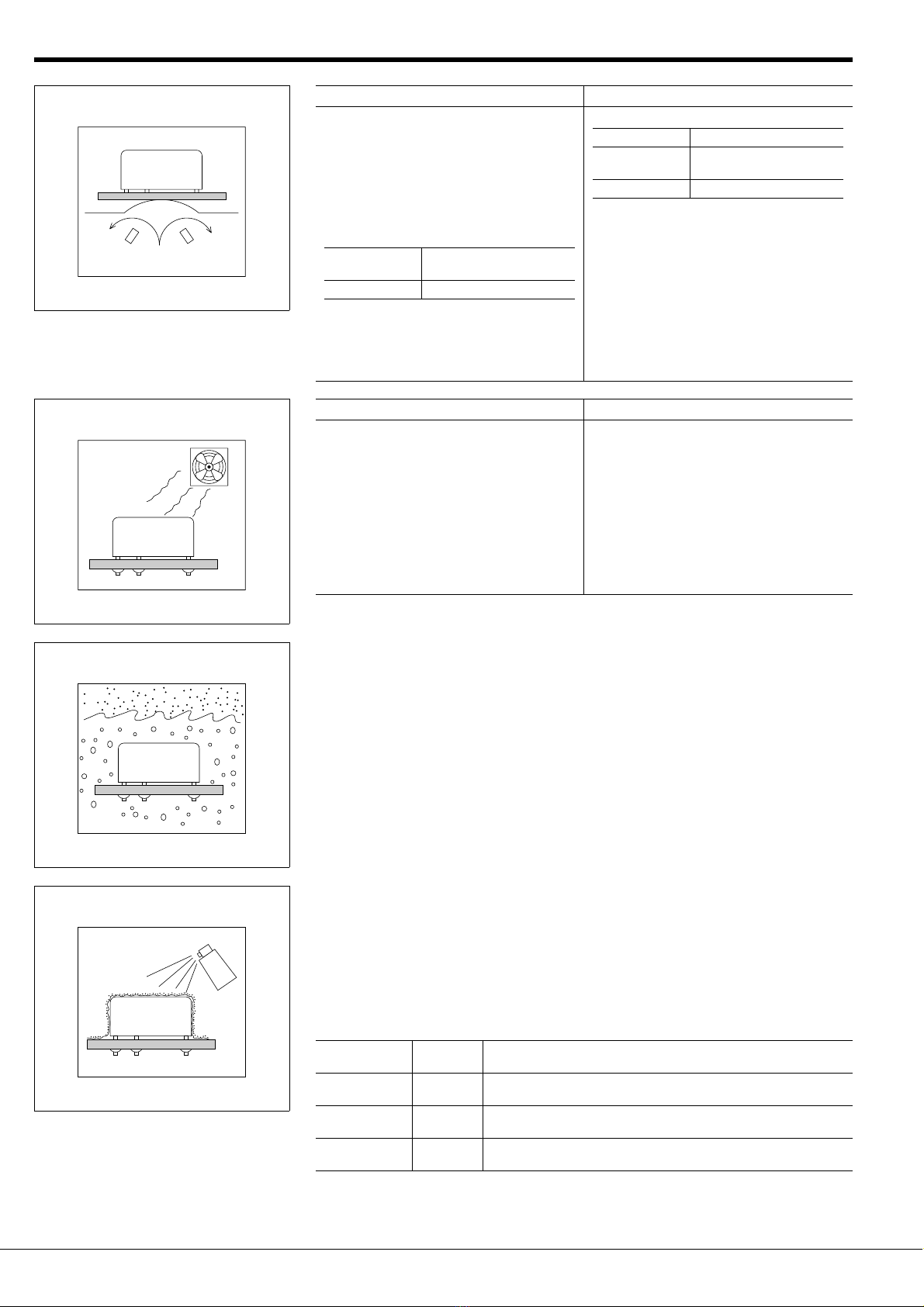

7. COATING

• If the PC board is to be coated to

prevent the insulation of the PC board

from deteriorating due to corrosive gases

and high temperatures, note the

following.

• Do not coat dust-cover type relays and

flux-resistant type relays, since the

coating material may penetrate the relay

and cause contact failure. Or, mount the

relay after coating.

• Depending on the type, some coating

materials may have an adverse affect on

relays. Furthermore, solvents (e.g.

xylene, toluene, MEK, I.P.A.) may

damage the case or chemically dissolve

the epoxy and break the seal. Select

coating materials carefully.

• If the relay and all components (e.g. ICs) are to be coated, be sure to carefully check

the flexibility of the coating material. The solder may peel off from thermal stress.

Type Suitability

for Relays Features

Epoxy-base Good • Good electrical insulation.

• Although slightly difficult to apply, does not affect relay contacts.

Urethane-base Care • Good electrical insulation, easy to apply.

• Solvent may damage case. Check before use.

Silicon-base No Good • Silicon gas becomes the cause of contact failure. Do not use the

silicon-base type.