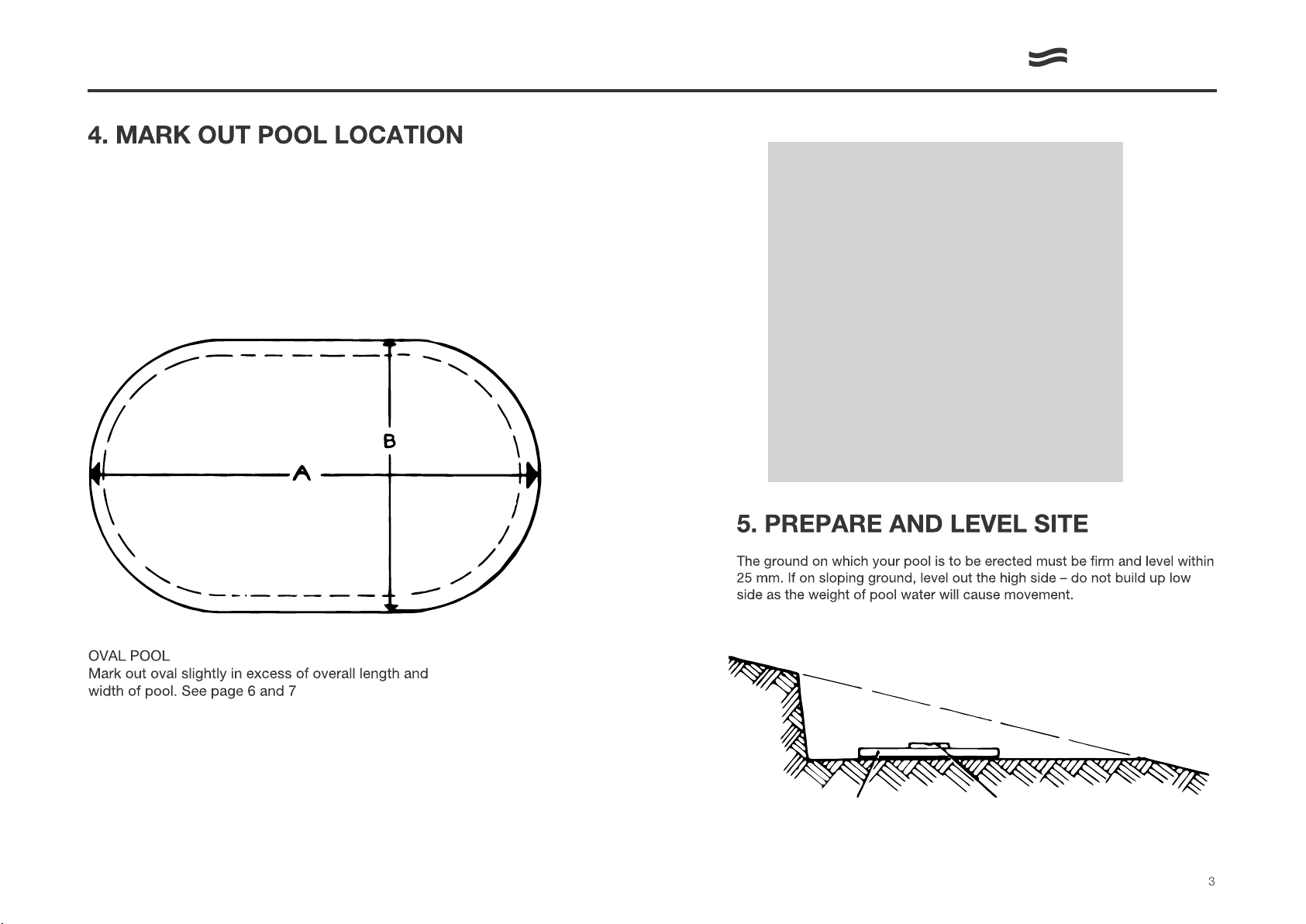

DO NOT FILL LOW SIDE OF EXCAVATION

Natural surface

Excavated leveled surface

Straight edge Carpenters level

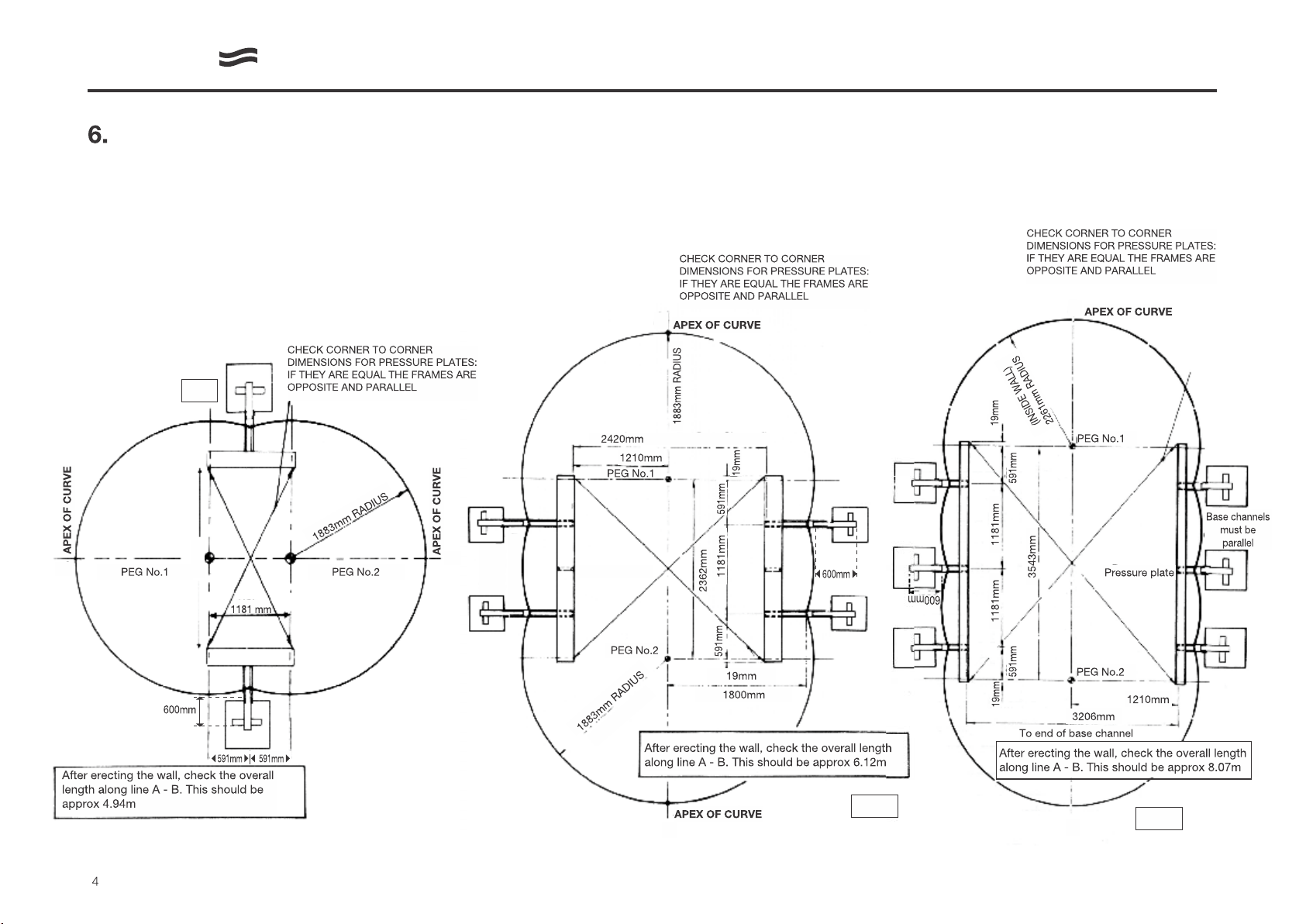

LIDO POOL

LINEAL MEASUREMENTS

(FOR TILING AND DECKING)

1612 – No.1 Wall x 1 = 14.254mtrs

2012 – No.2 Wall x 1 = 16.621mtrs

2412 – No.3 Wall x 1 = 18.989mtrs

2315 – No.3 Wall x 1 = 18.989mtrs

2715 – No.3a Wall x 1 = 21.356mtrs

3015 – No.4 Wall x 1 = 23.723mtrs

3815 – No.1 Wall x 2 = 28.508mtrs

1548 – No.1 Wall x1 = 14.254mtrs

1748 – No.2 Wall x 1 = 16.621mtrs

2048 – No.3 Wall x 1 = 18.989mtrs

When positioning the pool, ensure that its location

meets all Council By-Laws.

IN PLANNING THE LOCATION OF YOUR POOL, KEEP WATER

SAFETY IN MIND. APPROVED SITE SAFETY FENCING MUST BE

ERECTED AROUND THE WORKSITE.