1110

FOR SAFE OPERATION

FOR SAFE OPERATION

IMPORTANT

• Read this manual carefully until you completely understand and can

follow all safety and operating instructions.

• Keep this manual handy so that you may refer to it later whenever

questions arise. Also note, if you have any questions which cannot be

answered herein, contact Parker Brand.

• Always be sure to include this manual when selling, lending or

otherwise transferring ownership of this product.

• Never allow children or anyone unable to fully understand the

directions given in the manual to use the machine.

WORKING CIRCUMSTANCE

• Never start the engine inside a closed room or building. Exhaust gases

contain dangerous carbon monoxide.

• Never use the product:

1. When the ground is slippery or when you can’t maintain a steady posture.

2. At night, at times of heavy fog, or at any other times when your eld of vision

might be limited and it would be difcult to gain a clear view of the working

area.

3. During rain or lightening storms, at times of strong gale-force winds, or at any

other time when weather conditions might make it unsafe to use the product.

WORKING PLAN

• You should never use this product when under the inuence of alcohol,

when suffering from exhaustion or lack of sleep, when suffering from

drowsiness as a result of taking cold medicine or at any other time

when a possibility exists that your judgment might be impairs or that

you might not be able to operate the product properly and in a safe

manner.

• When planning your work schedule, allow plenty of time to rest. Limit

the amount of time over which the product is to be used continuously

to somewhere around 30-40 minutes per session, and take 10-20

minutes of rest between sessions. Also try to keep the total amount of

work performed in a single day under 2 hours.

• If you don’t observe the working time or working manner repetitive

strain injury could occur,

• If you feel discomfort, redness and swelling of your ngers or any other

part of your body, see a doctor before getting worse.

• To avoid noise complaints operate product between 9am and 5pm.

BEFORE STARTING THE ENGINE

• The area within a perimeter of 15m of the person using the product

should be considered a hazardous area into which no-one should

enter. If necessary, yellow warning rope and warning signs should

be placed around the perimeter of the area. When work is performed

simultaneously by two or more persons, care should be taken to

constantly look around or otherwise check for the presence and

locations of other people working so as to maintain a distance between

each person sufcient to ensure safety.

• Check the condition of working area to avoid any accident by hitting

hidden obstacles such as stumps, stones, cans or broken glass.

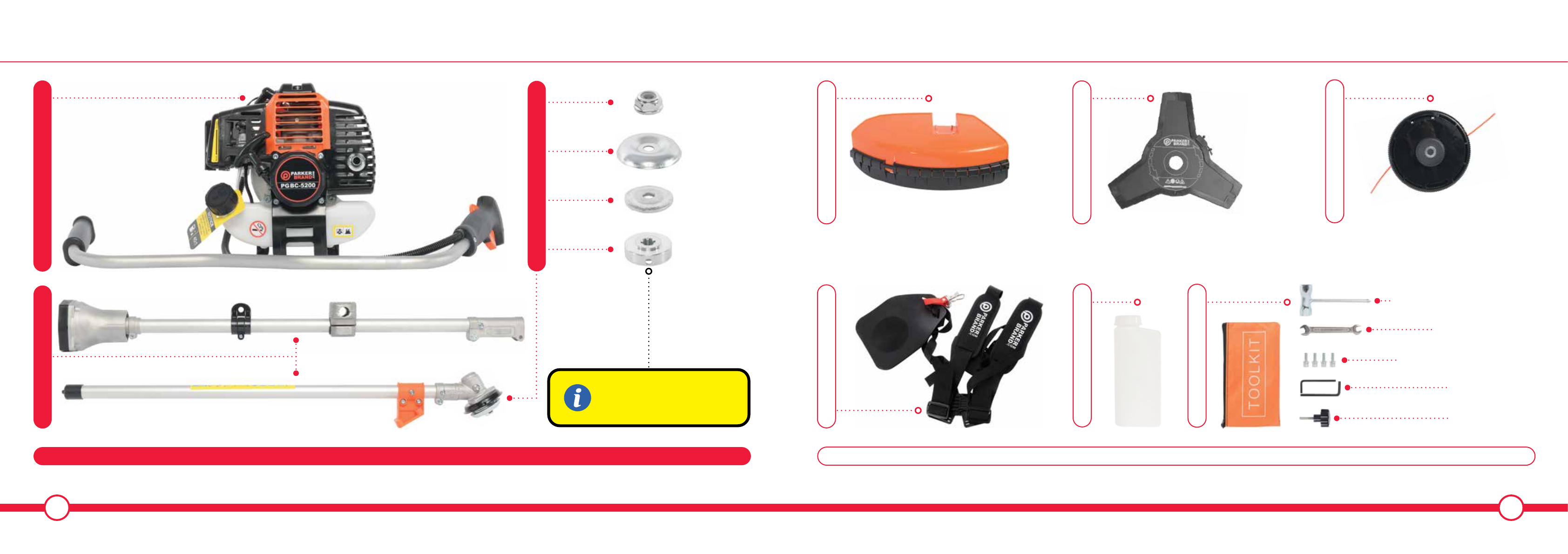

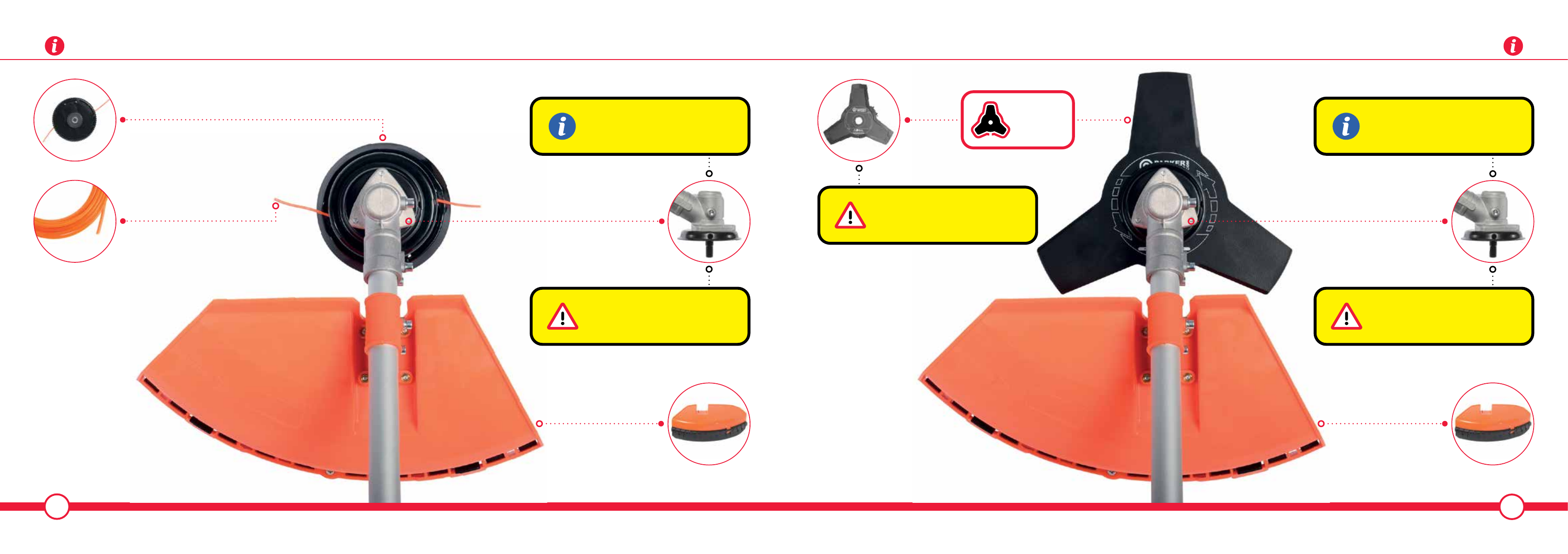

• Inspect the entire unit for loose fasteners and fuel leakage. Make sure

that the cutting attachment is properly installed and securely fastened.

• Be sure to attach the cutting attachment guard securely in place, or

you may injure yourself.

• Always us the harness. Adjust the harness for comfort before starting

the engine. The harness should be adjusted so the left hand can

comfortably hold the handlebar grip approximately waist high.

STARTING THE ENGINE

• Keep bystanders and animals at least 15m (50ft) away from the

operating point. If you are approached, immediately stop the engine.

• The product is equipped with a centrifugal clutch mechanism, so the

cutting attachment begins to rotate as soon as the engine is started

by putting the throttle trigger into the start position. When starting the

engine, place the product onto the ground in a at clear area and hold

it rmly in place so as to ensure that neither the cutting attachment

nor the throttle trigger come into contact with any obstacle when the

engine starts.

• After starting the engine, check to make sure that the cutting attachment

stops rotating when the throttle trigger is moved fully back to it’s original

position. If it continues to rotate even after the throttle trigger has been

moved fully back, turn off the engine contact Parker Brand.