179550500 Rev 2

Page 8 of 13

5 INSTALLATION

Please read and understand this document before installing the filter housing and accessories. Refer also to the

general safety information in Table 2.

Avoid subjecting the pressure equipment to external stresses.

Do not use the filter housing or accessories if there are signs of damage either to the

shell or sealing faces.

Ensure that connecting pipework is adequately supported, so as not to impose local

loads and vibrations onto the filter housing nozzles.

Check for any damage on receipt of the product; inform the supplier immediately of

any damage and await instructions whether to proceed.

Packaged filter housings should be stored in a dry environment.

Ensure the use of appropriate PPE during installation.

Ensure necessary and correct handling, assembly, tightening and checking of all joints

following installation and maintenance of the filter housing.

Ensure that no stray electrical currents are being transmitted to the filter housing that

may result in corrosion or perforation of metal parts; eliminate the source and /or

earth appropriately.

Perform a full system check before first use.

Filter housings may be heavy – follow site safety controls for manual or mechanical

handling to avoid harm.

Table 5

5.1 Receiving and Handling

a) Check for any damage on receipt of the product; inform the supplier immediately of any damage and

await instructions whether to proceed.

b) It is recommended to unpack the filter housing near to final installation location to avoid unnecessary

movement.

c) Use care when unpacking the filter housing to prevent damage to the contents.

d) Check that no small parts, documentation or certification are disposed of with the packing.

e) Filter housings may be heavy – follow site safety controls for manual or mechanical handling to avoid

harm.

f) Immediately notify the supplier if there are too many parts or if parts are missing and await instructions.

5.2 Storage

a) Packaged filter housings should be stored in a dry environment.

b) Use caution if stacking boxes and/or crates; always follow the instructions on the outside of packaging.

5.3 Installation Location

a) Protect the installed equipment from mechanical damage that may impact the integrity of the pressure

envelope (i.e. physical barriers and appropriate warning signs).

b) Ensure to check that the housing is not subject to vibration, thermal expansion and undue load on the

nozzles or connections.

c) Use appropriate supports to prevent stresses and moments on the filter housing nozzles.

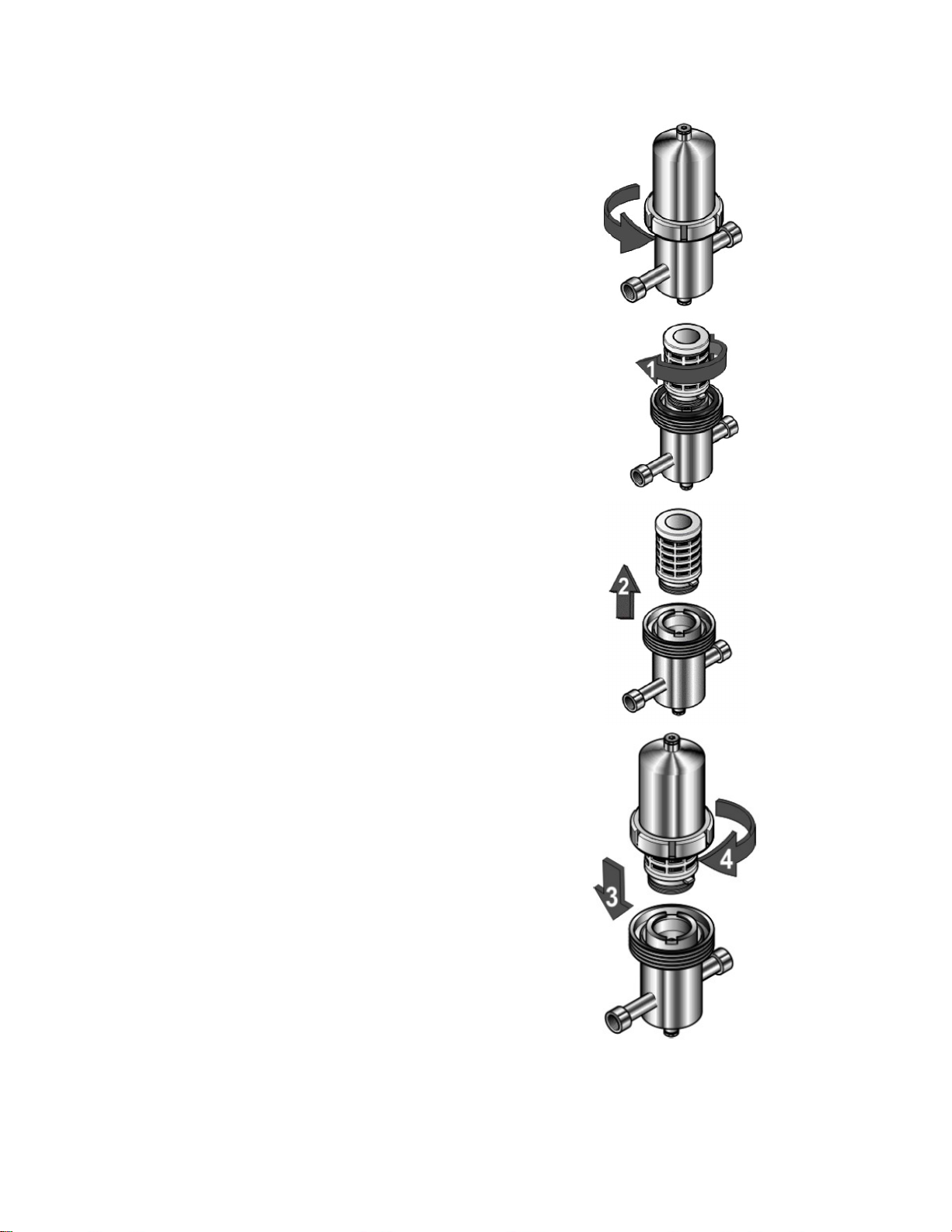

d) Ensure the filter housing is installed in a location with adequate clearance to allow cartridge change

out.

e) The filter housing should be installed so that accidental leaks cannot be dispersed into the environment.

f) Take all due measures to prevent fires that could impact the integrity of the pressure envelope.