6

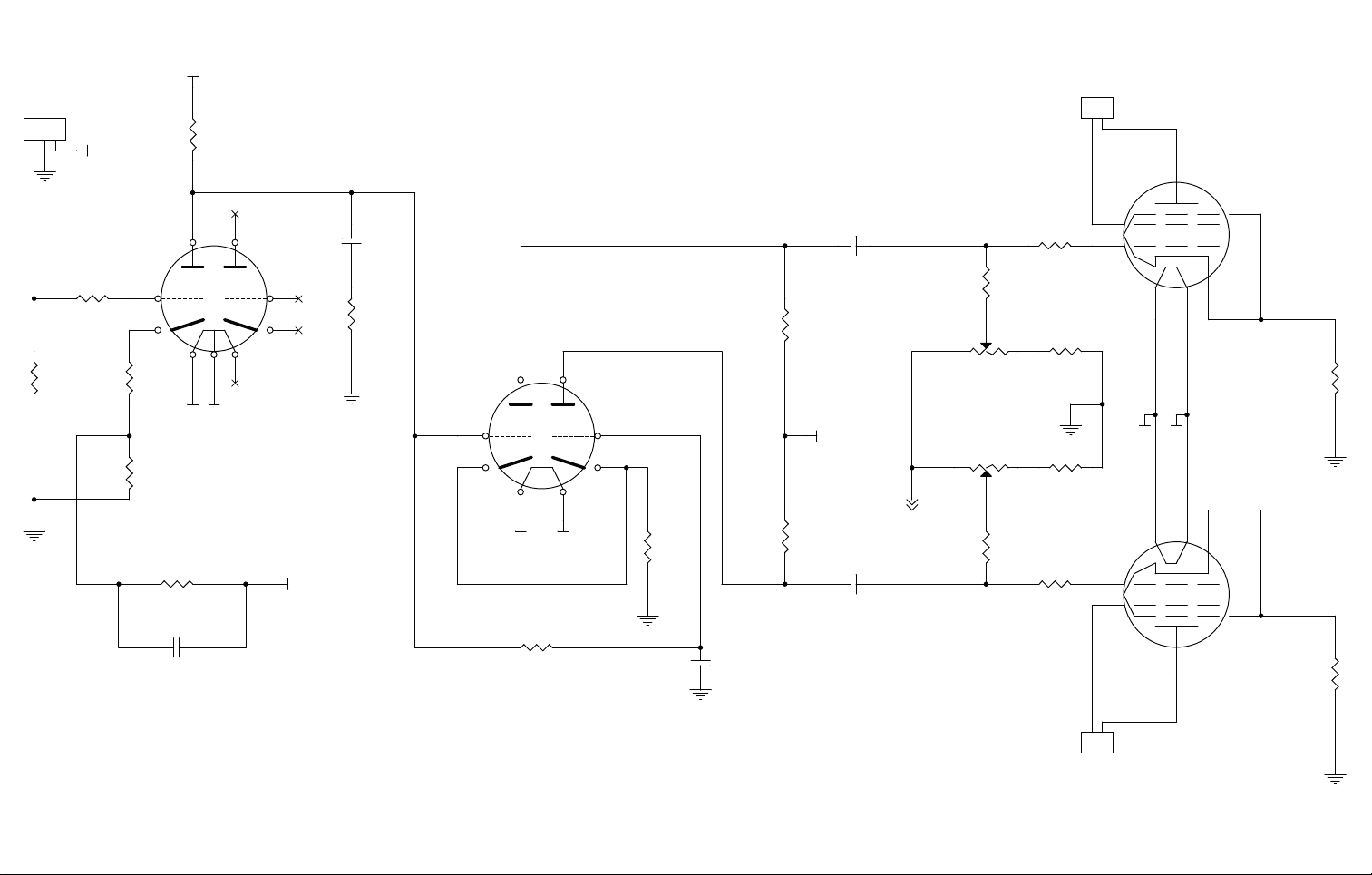

Ike PCB parts (one monoblock) Revised: 9/19/13

Tip: Put a dot in the checkbox if you have the part already as a quick

reference when ordering parts. X out the checkbox when you have installed

the part on the PCB.

Item QTY Reference Part Mouser Part Cost

______________________________________________________________________

1 R1 1K, 1/4W 71-RN60D-F-1K .11

1 R2 475K, 1/4W 71-RN60D-F-475K .11

3 R3,R17,R18 1K, 1/2W 71-RN65D-F-1.0K .26

3 R4,R41,R42 100, 1/2W 71-RN65D-F-100 .26

9 R5,R13,R14,R31, 100K, 2W 594-5083NW100K0J .10

R32,R33,R34,R35,R36

1 R6 1M, 1/2W 71-RN65D-F-1.0M .26

1 R7 18K, 2W 594-5083NW18K00J .10

1 R8 2K, 1/2W 71-RN65D-F-2.0K .33

1 R9 30K, 2W 594-5083NW30K00J .10

1 R10 33K, 2W 594-5083NW33K00J .32

2 R15,R16 25K Pot 72-T93YB-25K 1.59

2 R19,R20 15K, 1/2W 71-RN65D-F-15K .26

2 R21,R22 10, 1/2W 71-RN65D-F-10 .26

2 R27,R28 100, 2W 594-5083NW100R0J .10

1 R29 3.3K, 2W 594-5083NW3K300J .10

1 R30 200K, 2W 594-5083NW200K0J .10

1 R37 27K, 3W 283-27K-RC .21

1 R38 10K, 1/2W 71-RN65D-F-10K .26

2 R39,R40 wire jumper

1 R43 390K, 2W 594-5083NW390K0J .32

1 R46 IRCL 527-CL90 2.21

1 R49 3.3K, 1/4W 71-RN60D-F-3.3K .11

1 Rx53 10, 3W 283-10-RC .21

1 C2 .22uF, 250V 1431-2224K 1.03

2 C3,C4 .1uF, 630V 667-ECW-FA2J104J 0.55

1 C7 220pF, 500V 5982-15-500V220 .78

1 C8 470pF, 500V 5982-15-500V470 2.28

6 C9,C10,C11, 220uF, 400V 5985-380-400V221 4.32

C12,C13,C14

1 C15 22uF, 450V 647-UVZ2W220MHD 1.23

2 C16,C17 47uF, 250V 647-UVZ2E470MHD .93