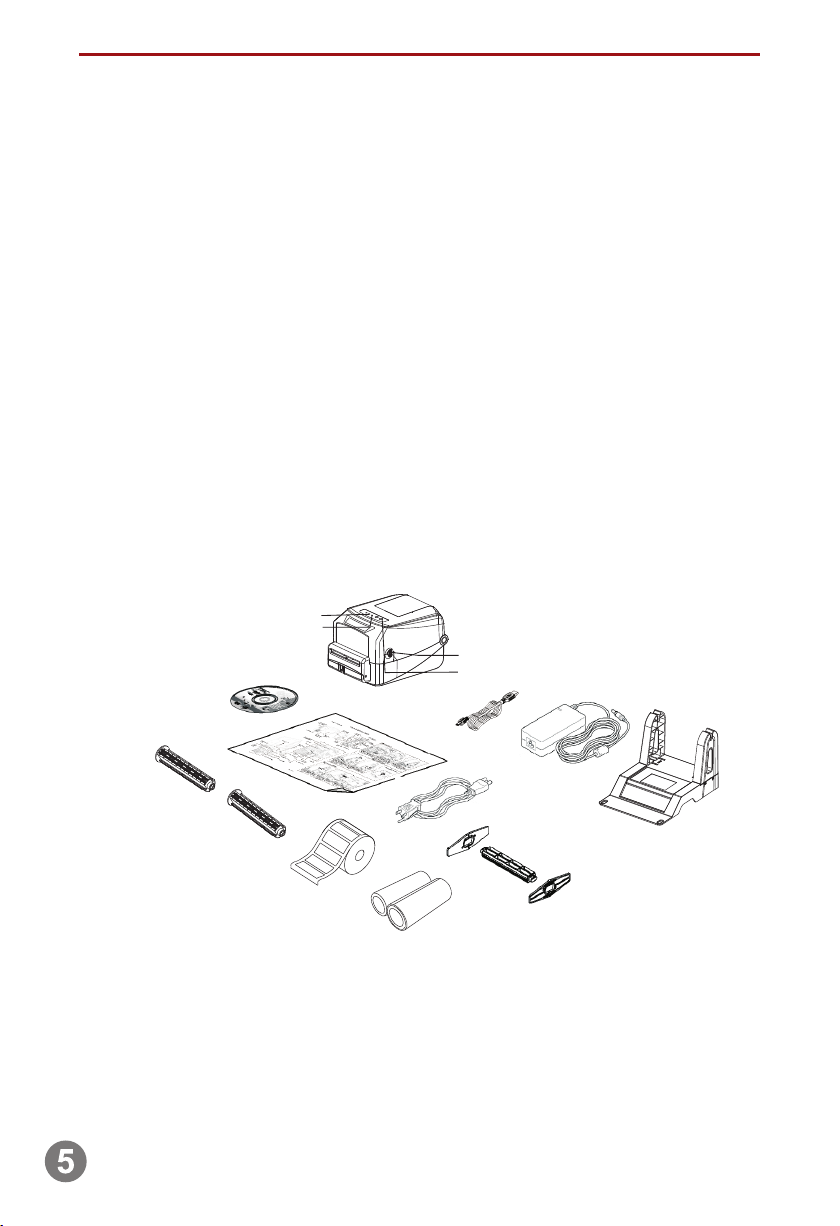

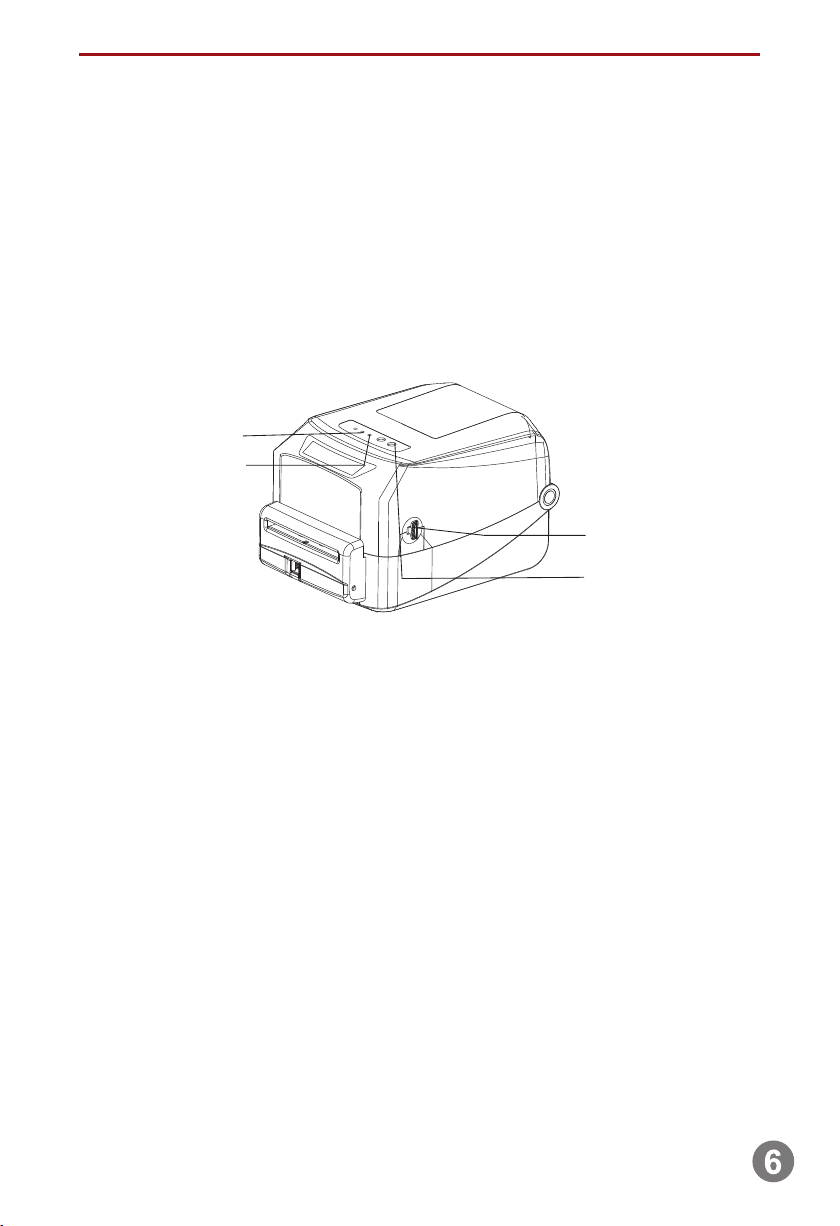

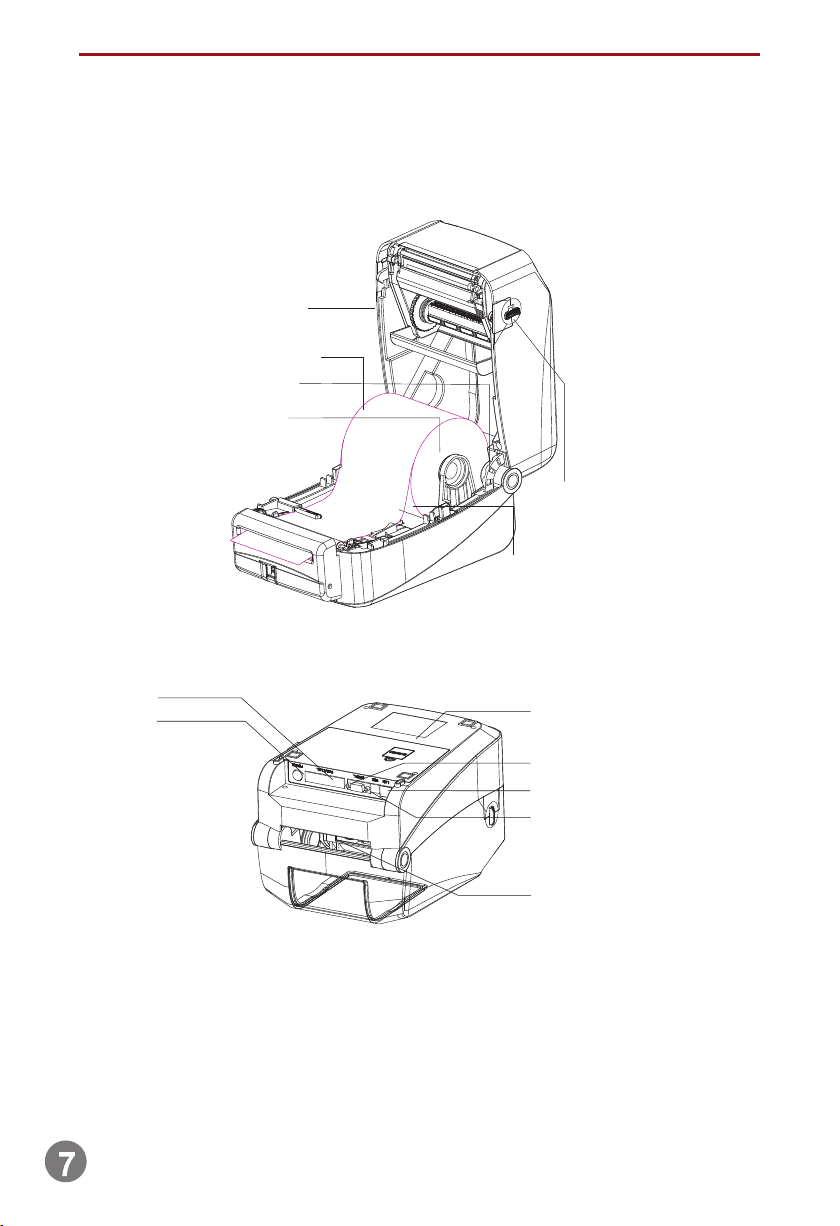

The printer

Introduction

Thanks for choosing series direct thermal and thermal transfer label printer.hLP-1625

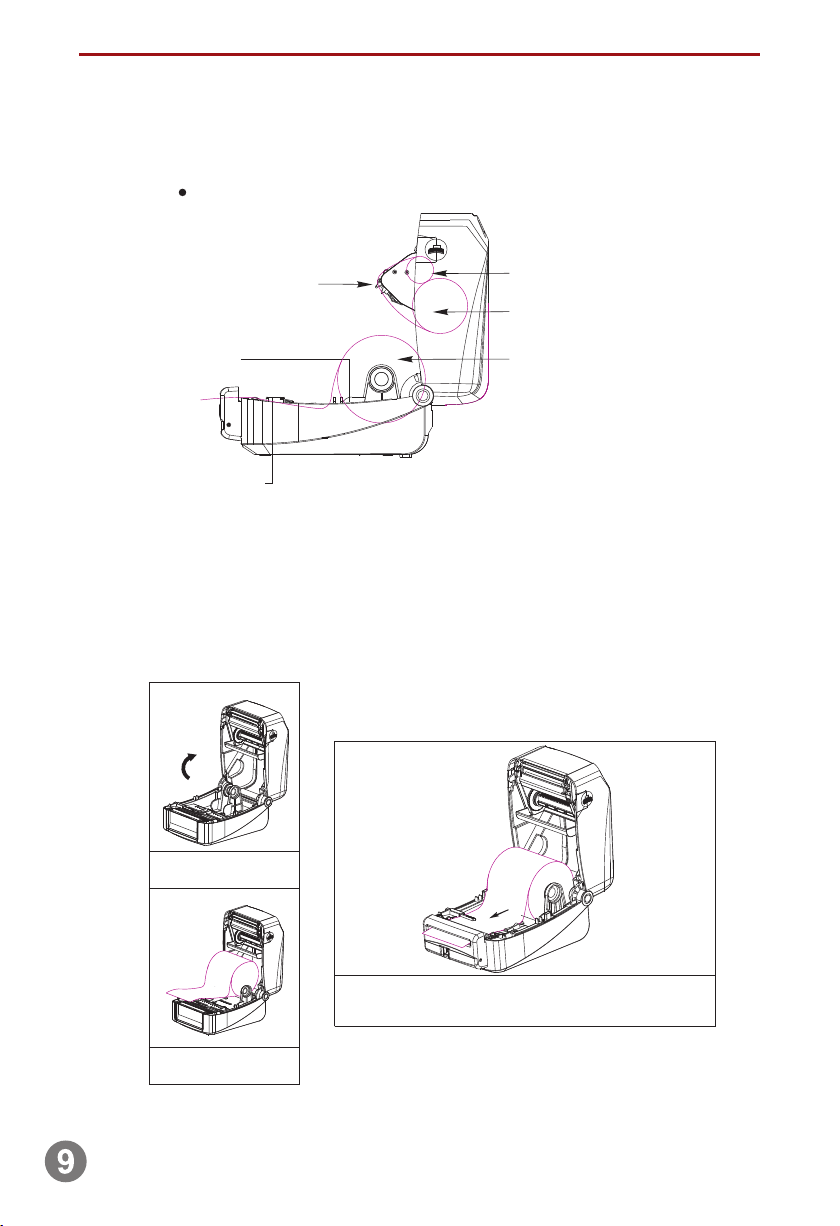

This series printer is built with 2 sets of gear to drive motor, with capability of handling 300

meters long ribbon and large label roll. Printer inner volume is fit for 5" OD (Outer Diameter)

paper roll, if using external paper holder, you can install 8.4"OD industrial grade label roll.

This printer is designed for real-time and batch label printing, with standard serial, parallel, USB

and Ethernet connection port. Direct thermal printing and thermal transfer printing modes are all

in one printer body, so you can choose various kinds of printing materials, for example: thermal

paper, plain paper, coated paper, silver paper, plastic paper etc.

Common 1D barcode and 2D barcode fonts are built inside printer, also it support 4 direction

printing, characters can be enlarged from 1 to 10 times. Besides, it supports 5 different size

bitmap fonts, OCR-A and OCR-B fonts, together with 203dpi higher print resolution, this series

printer are your best choice among the same class.

Declaration: This is a class A product, fit for Non Tropic regions installation This product .

may cause radio interference in life environment, users may need to take adequate preven

-tive measures.

Application Field

Manufacturing & Warehousing logistic industry

Healthcare

Parcel Post

Office & Studio

Retail

Product labeling and marking

Warehouse management label

Category marking label

Operation instruction marking label

Distributing instruction marking label

Patients marking

Medicine marking

Specimen marking

Mailing label

Price Label marking

Product item marking

Jewelry product marking

1.1

LP-1625 Manual