-- 4 --

DO NOT operate your chain saw near or

around flammable liquids or gases

whether in or out of doors. An explosion

and/or fire may result.

Do not fill fuel tank, oil tank or lubricate

when the engine is running.

USE THE RIGHT TOOL: Cut wood only.

Do not use the chain saw for purposes for

which it was not intended.For example, do

not use the chain saw for cutting plastic,

masonry, or nonbuilding materials.

The first time user should have practical

instruction in manual page 10 (barking

Saw horse) in the use of chain saw and

the protective equipment form an

experienced operator.

Do not attempt to hold the saw with one

hand only. You cannot control reactive

forces and you may lose control of the

saw, which can result in the skating or

bouncing of the bar and chain along the

limb or log.

Never run the chainsaw indoors.

Your chainsaw produces poisonous

exhaust as soon as the combustible

engine is started, which may be colorless

and odorless. To use this product can

generate dust, mists and fumes

containing chemicals known to cause

reproductive harm. Be aware of harmful

dust, mist (such as saw dust or oil mist

from chain lubrication) and protect your

self properly.

Wear gloves and keep your hand warm.

Prolonged use of chainsaws exposing the

operator to vibrations may produce

whitefinger disease. In order to reduce the

risk of whitefinger disease, please wear

gloves and keep your hand warm. If any of

the whitefinger symptoms appear, seek

medical advice immediately.

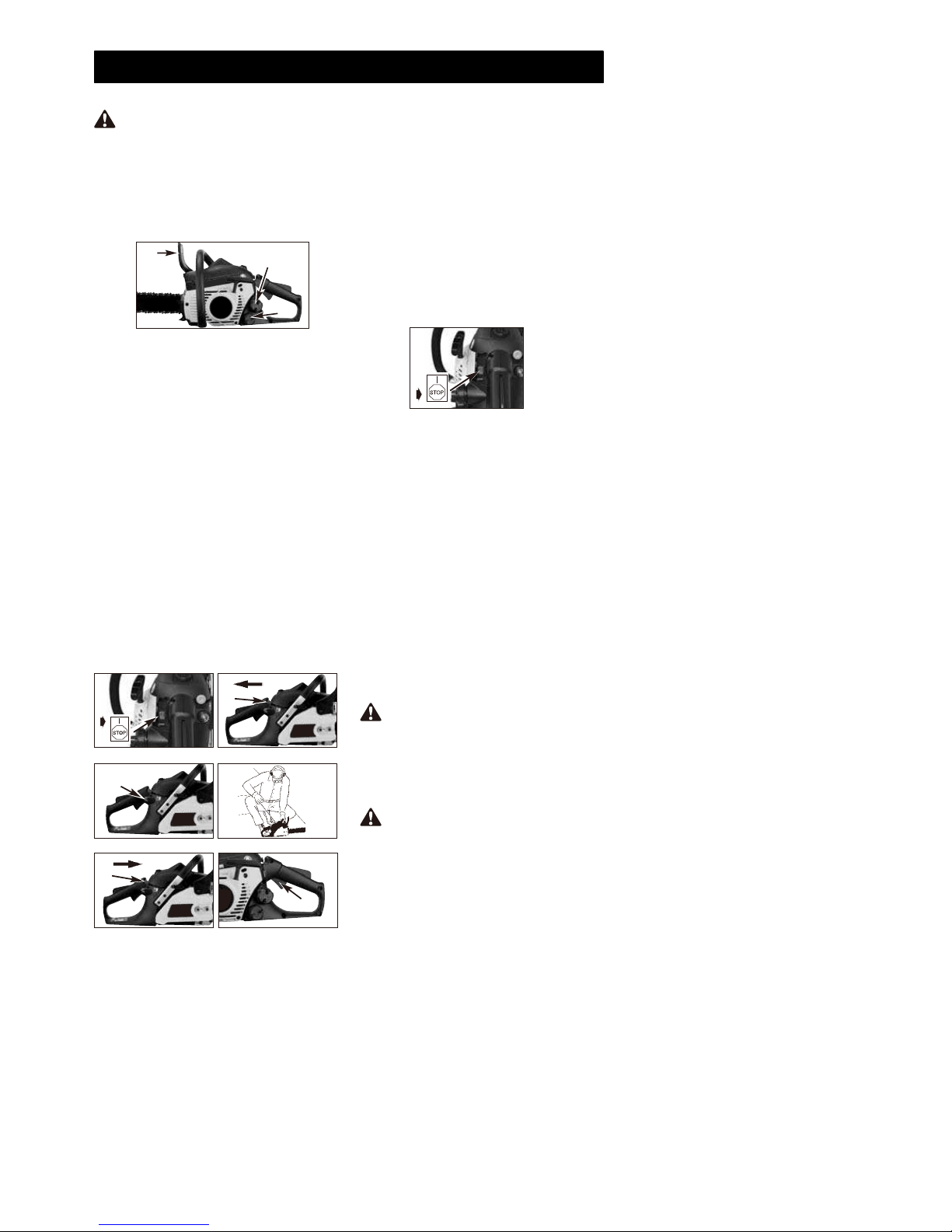

When transporting or storing the chain

saw always fit the guide bar cover.

Drive in the spiked bumper of the chain

saw directly behind the intended hinge

and pivot the saw around this point. The

spiked bumper rolls against the trunk.

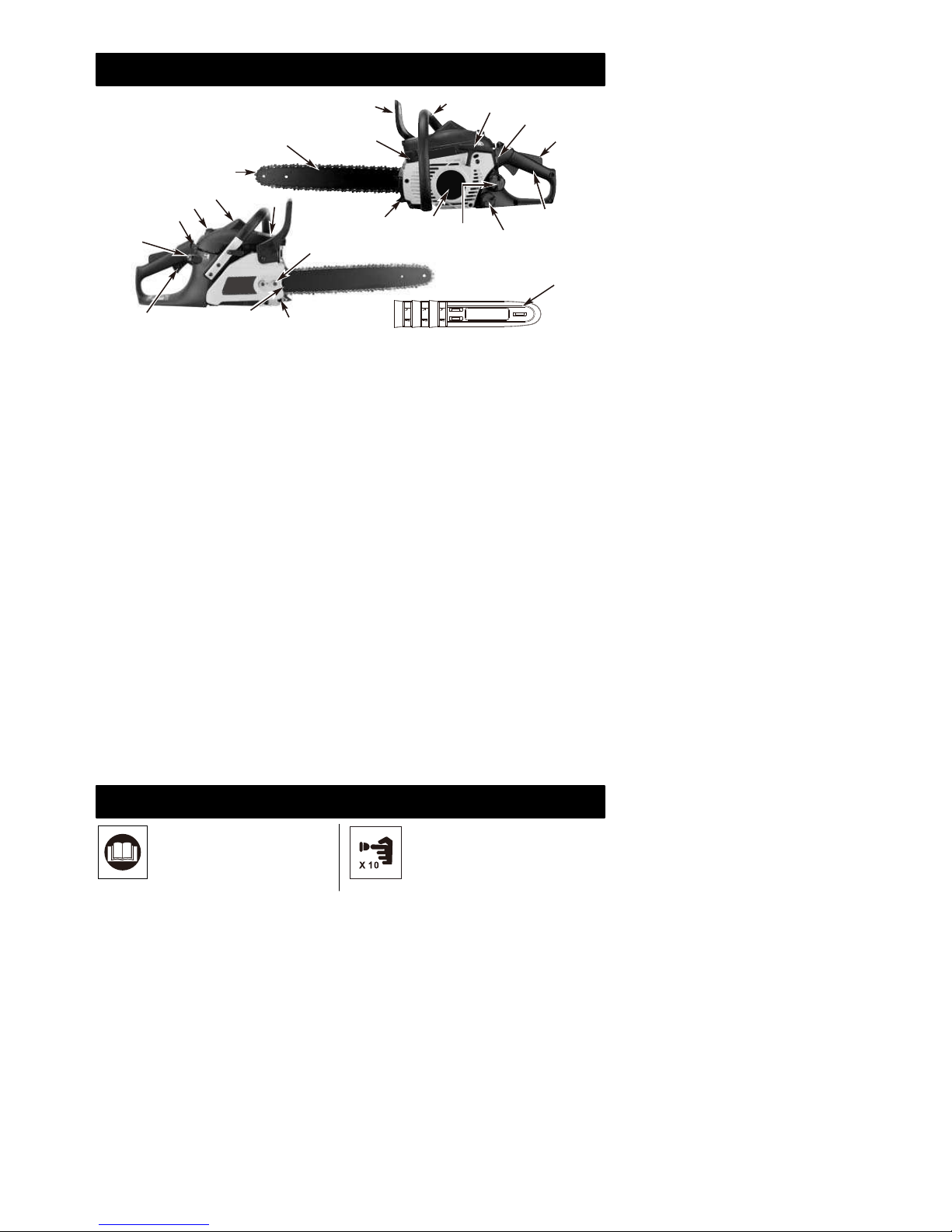

There are 3 parts only, chain, bar and

spark plug, can be replaced by the user

themselves and please use the same type

as showed on the specifications in the

user's manual.

(Type for the plug is NGK CMR7H).

If the other components beyond the prior

parts are defective, then please take your

tools to the nearest Authorized Service

Center for service.

NOTE: This appendix is intended primarily

for the consumer or occasional user. These

models are intended for infrequent use by

homeowners, cottagers, and campers, and

for such general applications as clearing,

pruning, cutting firewood, etc. They are not

intended for prolonged use. If the intended

use involves prolonged periods of opera-

tion, this may cause circulatory problems in

the user’s hands due to vibration.

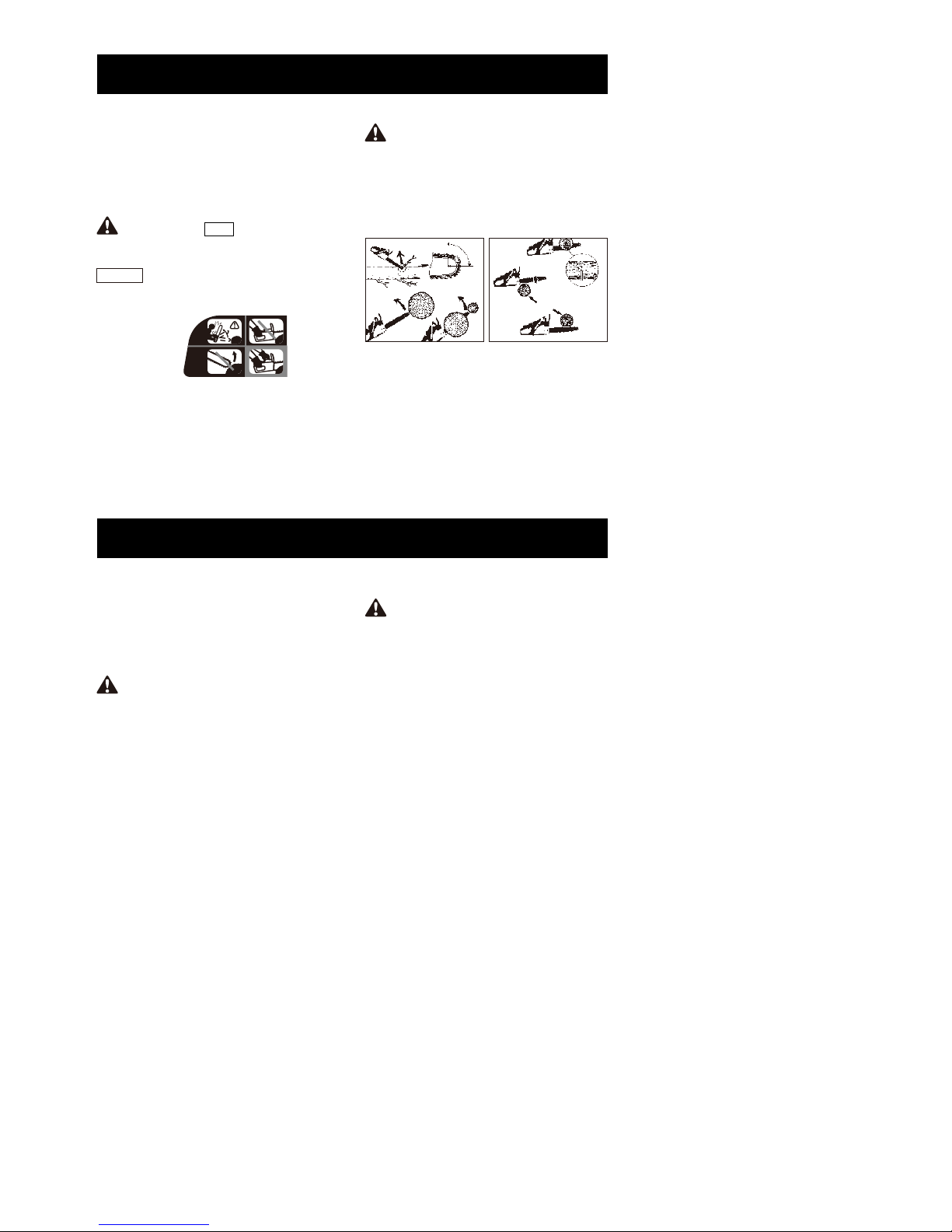

KICKBACK may occur when the NOSE or

TIP of the guide bar touches an object, or

when wood closes in and pinches the saw

chain in the cut.

Tip contact in some cases may cause a

lightning-fast reverse reaction, kicking the

guide bar up and back toward the operator.

PINCHING the saw chain along the

BOTTOM of the guide bar may PULL the

saw forward away from the operator.

PINCHING the saw chain along the TOP of

the guide bar may PUSH the guide bar

rapidly back toward the operator.

Any of these reactions may cause you to

lose control of the saw, which could result in

serious personal injury.

KICKBACK SAFETY PRECAUTIONS

1. With a basic understanding of kickback,

you can reduce or eliminate the element

of surprise.Sudden surprise contributes

to accidents.

2. Keep a good firm grip on the saw with

both hands, the right hand on the rear

handle, and the left hand on the front

handle, when the engine is running. Use

a firm grip with thumbs and fingers

encircling the chain saw handles. A firm

grip will help you reduce kickback and

maintain control of the saw. Don’t let go.

3. Make sure that the area in which you are

cutting is free from obstructions. Do not

let the nose of the guide bar contact a

log, branch, or any other obstruction

which could be hit while you are

operating the saw.

4. Cut at high engine speeds.

5. Do not overreach or cut above shoulder

height.

6. Follow manufacturer’s sharpening and

maintenance instructions for the saw

chain.

7. Only use replacement bars and chains

specified by the manufacturer or the

equivalent.

NOTE: Low-kickback saw chain is chain

that has met the kickback performance.