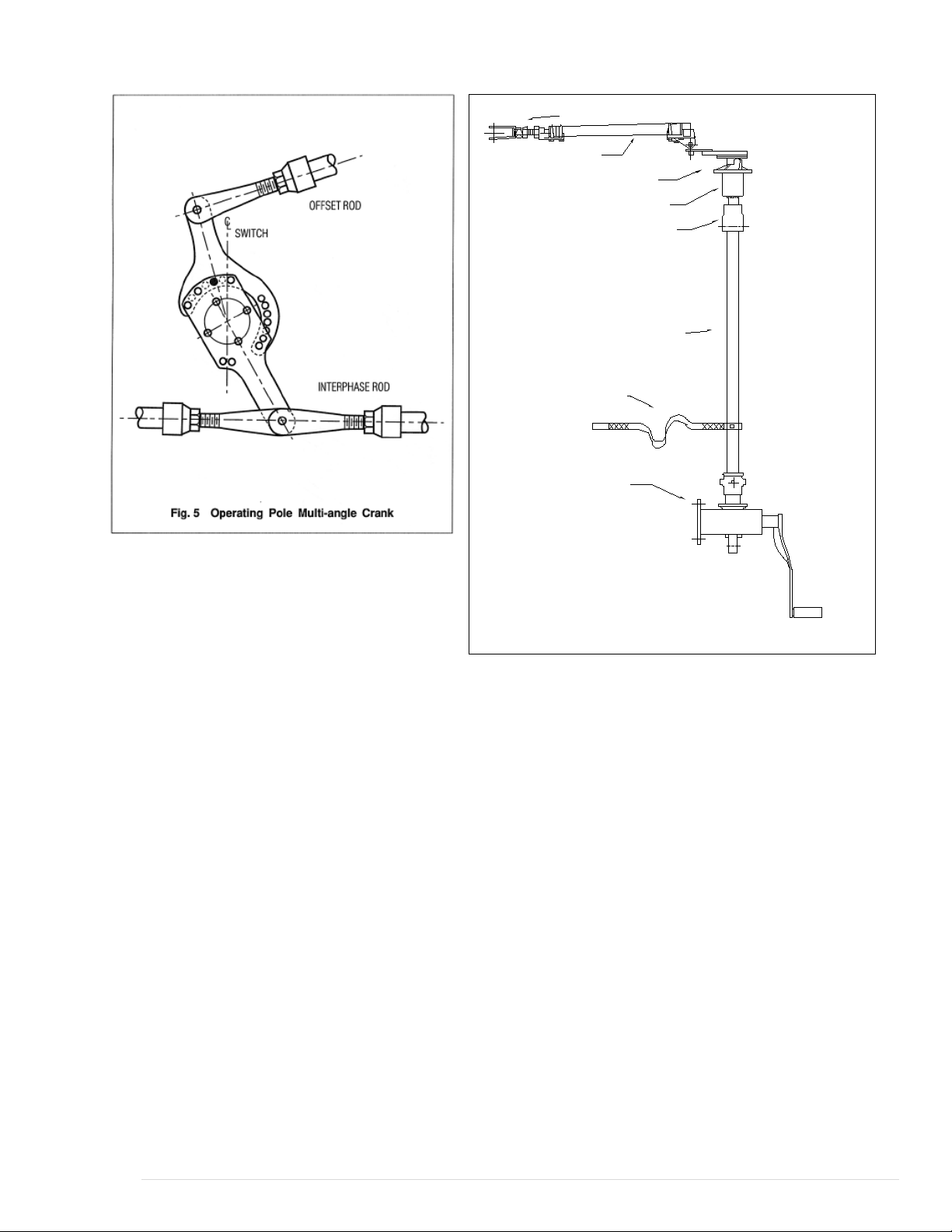

Step 11—Install Pipe Splice and Guide Plate

When the structure height exceeds 23 feet, a

pipe splice and a guide plate are furnished

and should be installed as shown in Fig. 6.

The pipe spice and both pieces of pipe are

predrilled to receive the 5/8” diameter pins.

The guide plate should not be solidly

mounted until after the vertical pipe has

been completely installed. Then bolts

holding the guide plate on the structure

should be tightened in order that the holes in

the guide plate line up with the normal

position of pipe. This assures that there is no

binding.

Step 12—Install Operating Mechanism

Either a swing handle or a worm gear

mechanism is (normally) supplied for

manual switch operation.

Swing Handle Operator

To install the swing handle operator:

With ground strap in place on vertical operating

pipe, slide handle and handle lock plate over the

end of the vertical operating pipe. Fasten the

lock plate at the proper location. Recommended

height for the lock plate is 3 ft. 6 in. above

ground.

Note: The lower end of the vertical operating

pipe should extend through the lock plate at

least 3 inches. It may extend as much as 3 feet

or more, just so it doesn’t touch the ground or

column footing.

The lock plate assembly consists of two

castings, mounted on the pipe guide plate, which

can be easily adjusted in an arc to provide the

required rotation. These act as locks for the

manual operating handle when it is dropped

from the operating position. The handle must be

raised to a horizontal position for operation.

With the switch in the fully closed position, set

the handle clamp so its set screws are 4 inches

above the lock plate and its vertical centerline is

at or near as possible to the closed position.

Temporarily fasten the handle to the pipe with

the set screws. Operate the switch and move the

adjustable lock castings until they exert pressure

against the handle in both the open and closed

positions of the switch. This provides a slight

torsional wind-up in the operating pipe. Tighten

the two piercing set screws on the handle clamp

until holes are punched into the pipe and

continue until the screws are firmly seated.

Worm Gear Mechanism

With ground strap in place on vertical operating

pipe, slide worm gear mechanism (Fig. 8) over

the vertical operating pipe and attach it to the

structure. Remove the small position indicators,

which are attached to the worm gear coupling

with Allen set screws. Tighten hex head set

screws in the coupling until the vertical

operating pipe is pierced. The three-pole switch

should now be operated manually to check for

proper adjustment. If all stops at switch

elevation have been set, including the offset

bearing, then it is safe to reinstall the position

indicators on the worm gear mechanism. These

indicators should not quite touch the raised boss

on the worm gear housing in either the open or

closed position. There is a possibility of damage

to the indicators or the coupling if this is not

observed

Motor Operator

For remote operation, a motor operator is

supplied and it should be installed per the

instructions supplied with it.

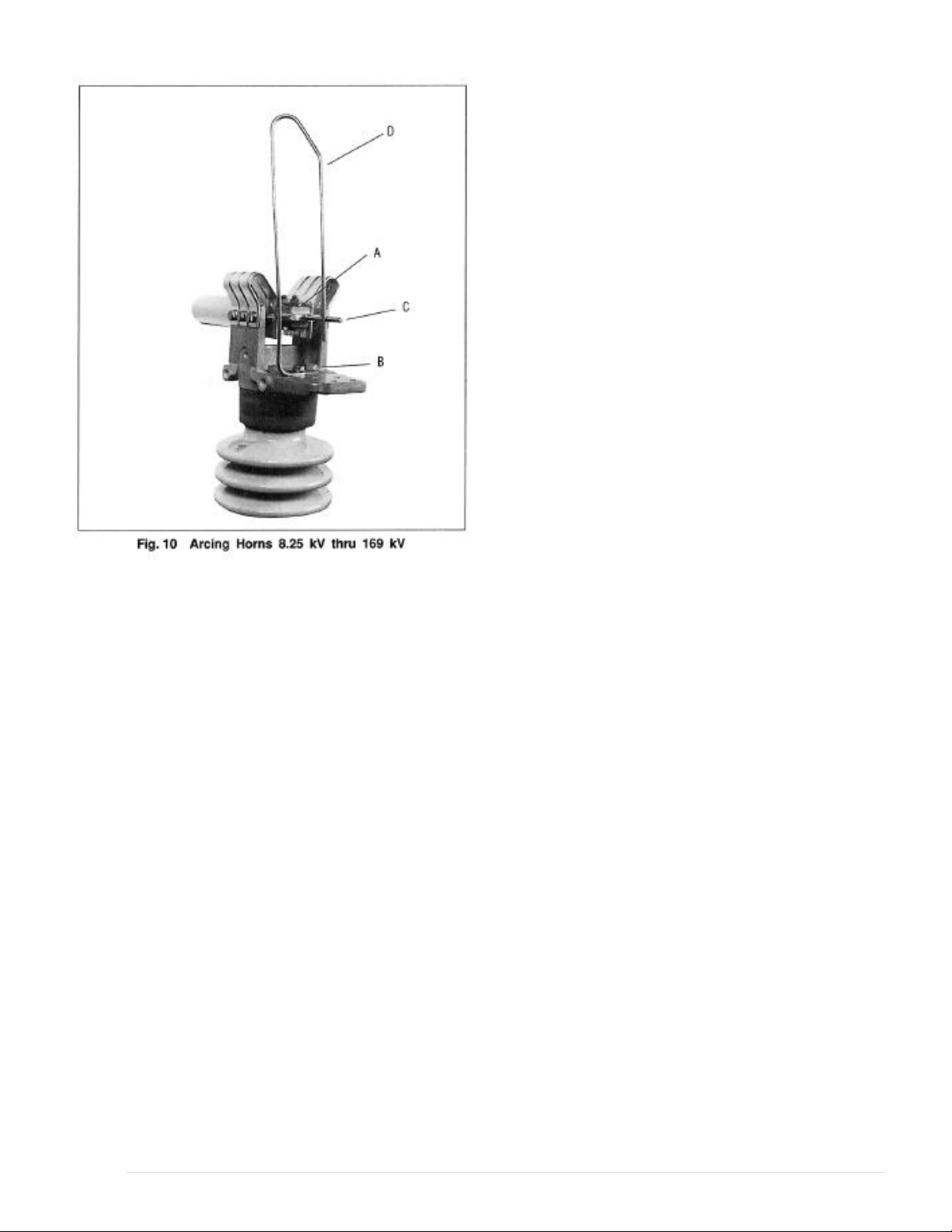

Step 13—Arcing Horn Installation (When

Supplied)

When arcing horns are used on switches, they

should be installed and adjusted after mounting

the switches on the structure. Arcing horns are

furnished only when horn gap switches are

ordered. Fig. 10 shows arcing horns used on

switches 8.25 thru 169 kV. The movable strait

horn (C) is assembled be screwing it into the

blade end. Tighten the locking nut seat securely

against the end of the blade (A). The stationary

horn is positioned properly on the jaw with the

saddle clamp, and bolted (B). This stationary

horn should be adjusted or even bent slightly to

give light contact pressure between the two

horns over the entire length if the movable horn.

Arcing horns for 242 kV switches are essentially

the same as Fig 10 with the stationary horn

contacting the movable horn at the surface

between the end of the blade and small corona

ball which is affixed at the end of the movable

horn.

Arcing horns for switches 362 thru 8000kV do

not use a movable horn. Instead the stationary