!! !!!"#$%&!

!

If you smell gas:

!

!

!!'"&#(#$!

!

!

!

!

!

!

!!!"#$%&! ! ! )"&*+#,-+#+.(!%,/"00"&!,

,

1234,56673589:,958,6;<=>9:,95;?<8,@<8<A3=:,

B2392,254,8<,<=<;C,

,

D438E,3F,38,58,:897<4:=,4659:,958,G377,H<>C,

,

#:I:;,>4:,F234,56673589:,38,58,:897<4:=,4659:,

4>92,54,5,95@6:;J,F:8FJ,95;,<;,2<@:C,

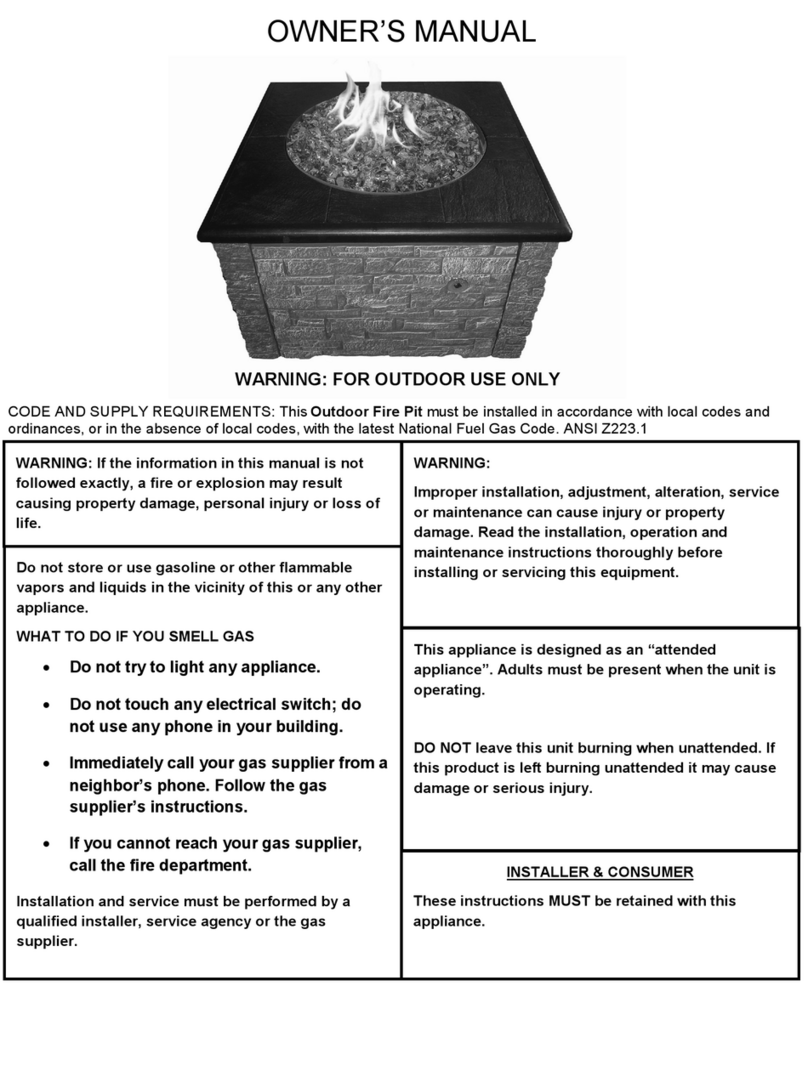

'"&#(#$-!!"#!03)!2/#%1(,02%/!2/!03)')!2/'01&902%/'!2'!/%0!#%**%?)7!)@,90*$A!,!#21)!%1!

)@6*%'2%/!(,$!1)'&*0!9,&'2/+!61%6)10$!7,(,+)A!6)1'%/,*!2/B&1$!%1!7),03:!

!

K+&,L+D&,M"K%1L,

.%!/%!'0%1)!%1!&')!+,'%*2/)!%1!%03)1!#*,((,4*)!5,6%1'!,/7!*28&27'!2/!03)!5292/20$!%#!

032'!%1!,/%03)1!,66*2,/9):!

!! !!'"&#(#$!

!

'"&#(#$,

.%!/%0!*),5)!&/,00)/7)7!7&12/+!&'):!

.%!/%0!&')!#%1!9%%D2/+:!

E%**%?!,**!+,'!*),D!61%9)7&1)'!2/!032'!

(,/&,*!612%1!0%!%6)1,02%/:!

Do not store or use gasoline,or other

flammable vapors and liquids, in the

vicinity of this or any other appliance.

An LP-cylinder not connected for use

shall not be stored in the vicinity of

this or any other appliance.

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. If odor continues, keep away

from the appliance and

immediately call your gas

supplier or fire department.

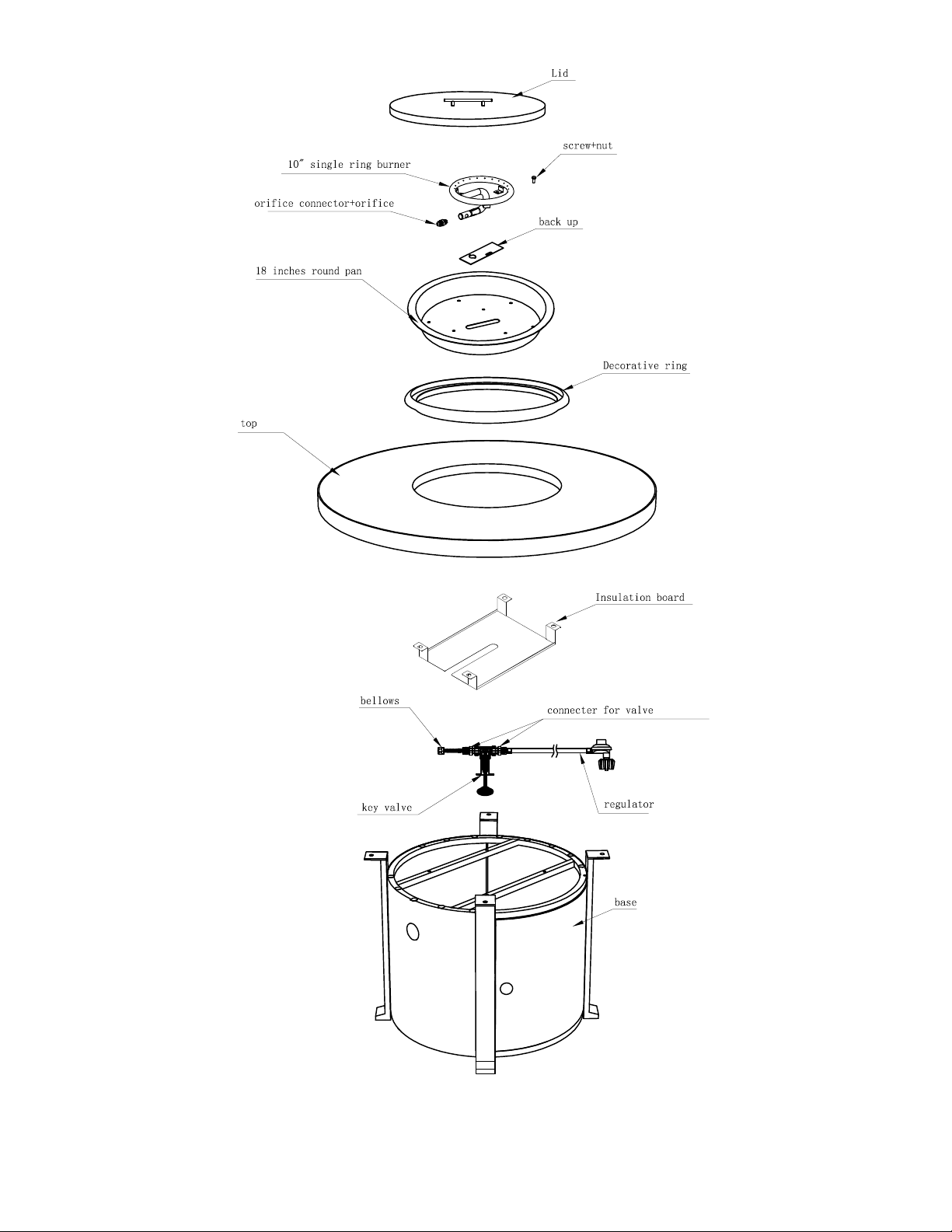

Importer installation, adjustment,

alteration, service or maintenance

can cause injury or property damage.

Read the installation, operating, and

maintenance instructions throughly

before installing or servicing this

equipment.