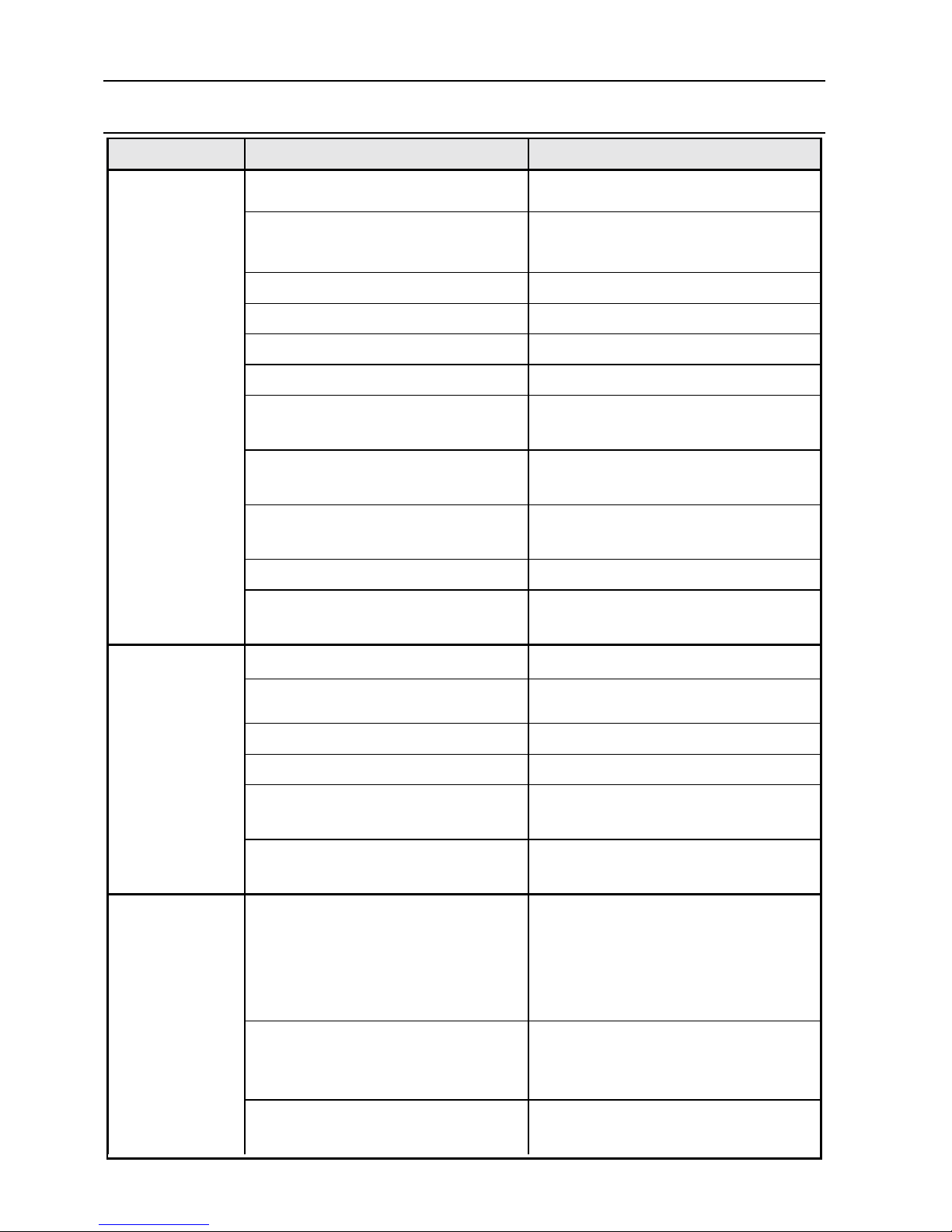

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Will not start Incorrect power supply and/or

wiring.

Make sure power is turned

on. (Consult with a licensed

electrician).

Air receiver is at full pressure. Drain air receiver.

Low pressure Safety valve leaks. Replace safety valve.

Drain cock open. Close drain cock.

Loose tubes or ttings. Tighten ttings.

Dirty or plugged air lter. Clean or replace as necessary.

Defective unloader valve. Replace unloader valve.

Oil in

discharge

Too much oil in the crank-

case.

Drain oil and ll to proper level.

Improper oil viscosity. drain and replace oil

Compressor overheated. Air pressure regulated too

high.

Restricted air lter. Clean or replace air lter.

Worn piston rings. Replace piston rings.

Compressor

overheats

Dirty compressor head, cylin-

der or intercooler.

Clean with compressed air.

Clogged inlet lter. Clean or replace as necessary.

Operating pressure too high. Reduce operating pressure.

Low oil or wrong oil being

used.

Drain and replace oil.

Compressor cycle too long.

Proper cycle is 50-60% on

Stop/Start operation.

Allow for longer rest between

cycles.

Leaks in air system. Check for leaks.

Compres-

sor loads &

unloads or

stops & starts

excessively

Pressure switch differential

adjusted too close.

Replace worn components as

necessary.

Make necessary adjustments.

Defective compressor valves. Replace valves.

Compressor too small for

intended use.

Upgrade to larger compressor.