12

Tool Specifications

Compressor K 210 K 290 K 410

Article number 0701 221 0701 229 0701 241

Intake air quantity 185 l/min 284 l/min 366 l/min

Effective delivery quantity 105 l/min 152 l/min 180 l/min

Rated input 1.5 kW 2.2 kW 2.2 kW

No-load speed 2850 min-1 2850 min-1 2850 min-1

Oil quantity 0.2 l 0.35 l 0.44 l

Oil type ISO 100 ISO 100 ISO 100

Rated voltage 230 V 230 V 230 V

Insulation class F F F

Safety class / II / II / II

Maximum pressure 8 bar 10 bar 10 bar

Reservoir content 9.5 l 20 l 50 l

Cylinder bore 47 mm 55 mm 47 mm

Stroke 37 mm 42 mm 37 mm

Fuse protection 7 A 10 A 16 A

Ambient temperature +5 - +40 °C +5 - +40 °C +5 - +40 °C

Length/width/height 400/320/630 mm 480/410/800 mm 880/350/700 mm

Weight approx. 18 kg 33 kg 46 kg

For Your Safety

Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result in electric

shock, fire and/or serious injury.

Save all safety warnings and instructions for fu-

ture reference.

Working safely with this machine

is possible only when the opera-

ting and safety information are

read completely and the instruc-

tions contained therein are strictly

followed.

Before each use of the machine,

check the cable and plug. If dam-

age is detected, do not use the ma-

chine. Have repairs performed

only by a qualified technician. Nev-

er open the machine yourself.

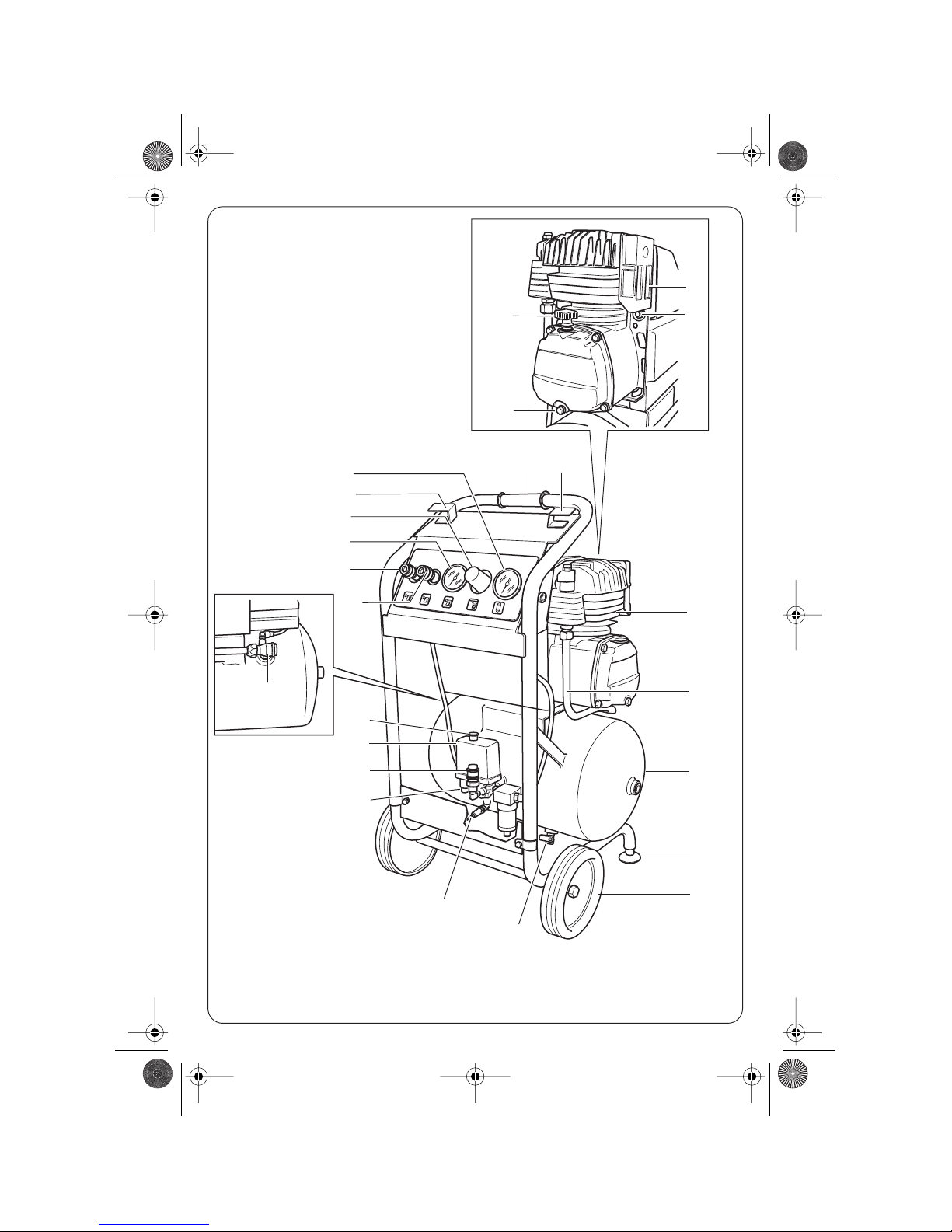

❏Compressors should only be operated and serv-

iced by trained personnel.

❏The operator of this machine is responsible for

observing the valid instructions, and in particu-

lar for adhering to the scheduled testing times

for the compressed air reservoir and the regula-

tions for the prevention of accidents (VGB 16).

❏The safety valve 14 has been secured against

becoming altered. The blow-off pressure pre-set

by the manufacturer must not be changed.

❏No changes may be made on the machine by

the customer, in particular, the compressed air

reservoir 17.

❏Caution! Danger of burning! When the plant is

in operation, the unit and pressure tube 2 be-

come hot.

❏Do not place any inflammable objects in the vi-

cinity of the compressor.

❏Keep children and animals away from the op-

erating area and thereby prevent any injuries

being caused by equipment connected to the

compressor.

❏Do not operate the compressor without an air

filter.

❏Do not move the compressor if the reservoir is

under pressure.

❏Before commencing any work on the machine,

pull out the mains plug and ensure that the plant

is depressurised.

❏Use only original Würth parts and accessories.

GB

☞For further notes on safety refer to enclosed Sheet

0701 221.book Seite 12 Mittwoch, 2. Juni 2010 1:38 13