Thunder Scientific Corporation ACS3920 Air Compressor System 4

Document Number: ACS3920.doc - Edition 04 - Nov 2021

1 INTRODUCTION

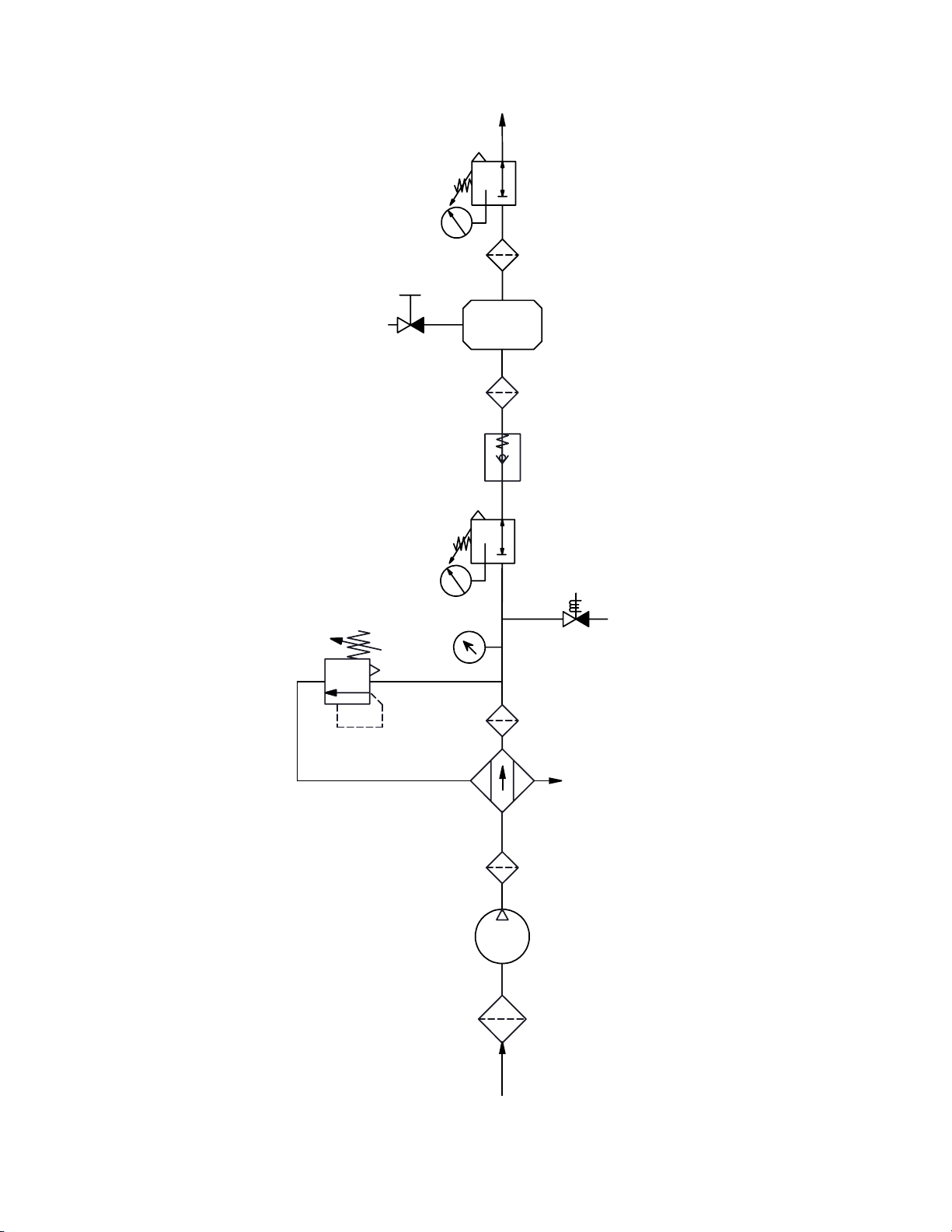

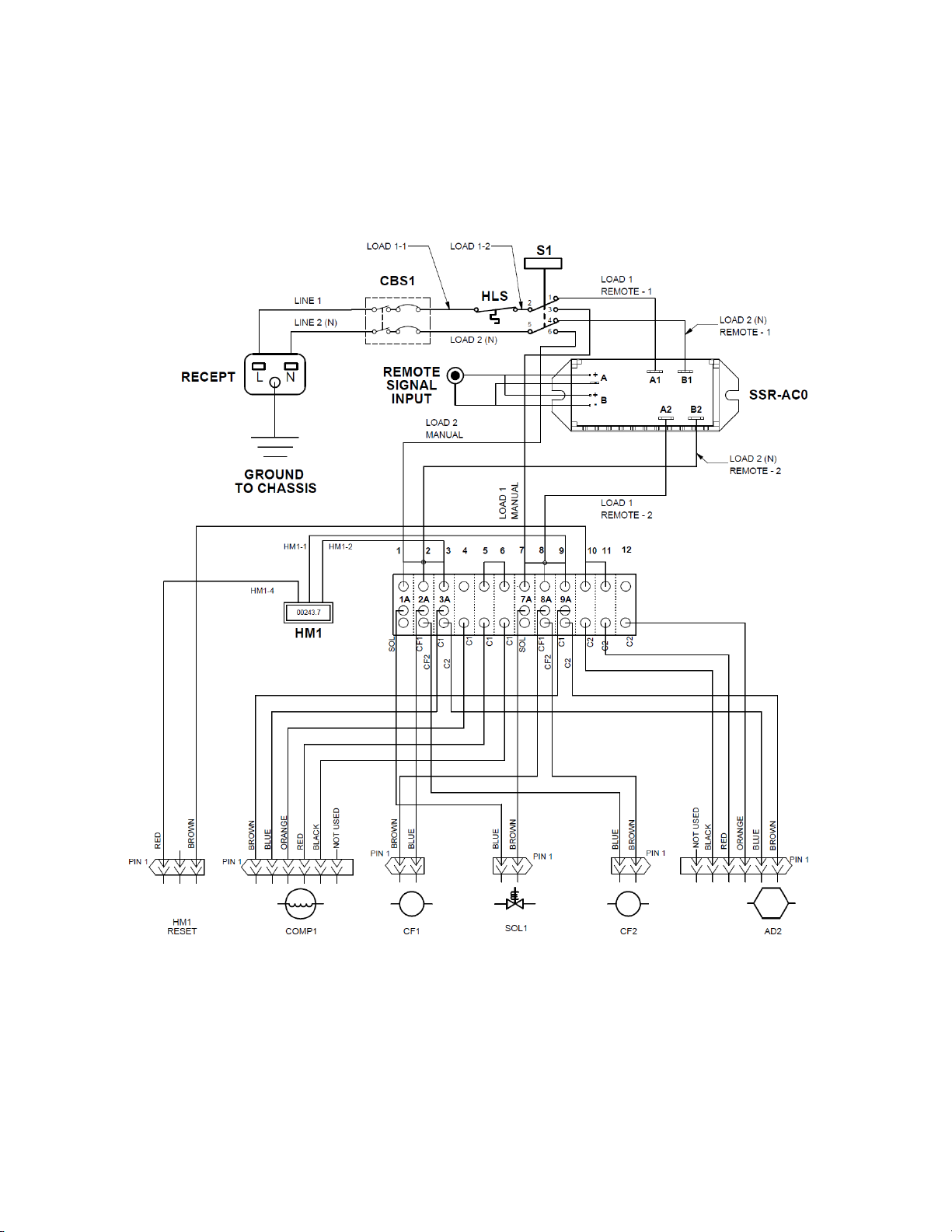

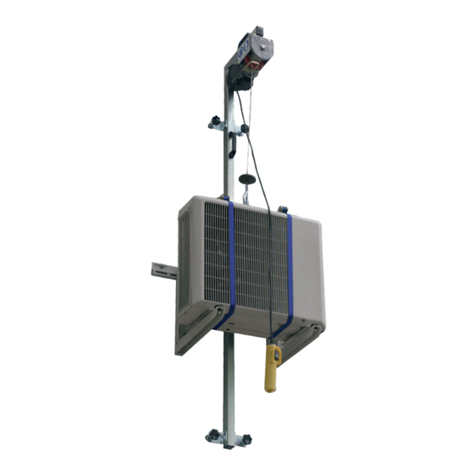

The ACS3920 Air Compressor System with integral CO2 Adsorber/Dryer is designed to be used

as the gas supply for the Thunder Scientific 3920 Low Humidity Generator. The ACS3920 Air

Compressor System consists of a vibration isolated oil-less compressor, membrane style air

dryer, CO2 Adsorber/Dryer, and adjustment regulators, all incorporated into a sound muffling

cabinet. The ACS3920 is ideal for laboratory use because of its 100 psiG pressure output at 10

L/min capability, 100% duty cycle, low sound level of less than 70 db(A), and long service life.

NOTE: When using the ACS3920 with a Model 3920 or Model 3900 low humidity generator the

working range of the generator will be limited by the lower pressure and overall dryness outputted

by the ACS3920. You will only be able to generate down to around a -70 °C frost point when

using the ACS3920. It is also important to adjust the internal Model 3920 or Model 3900

regulator to 80 to 90 psiG to assure proper pressure control.

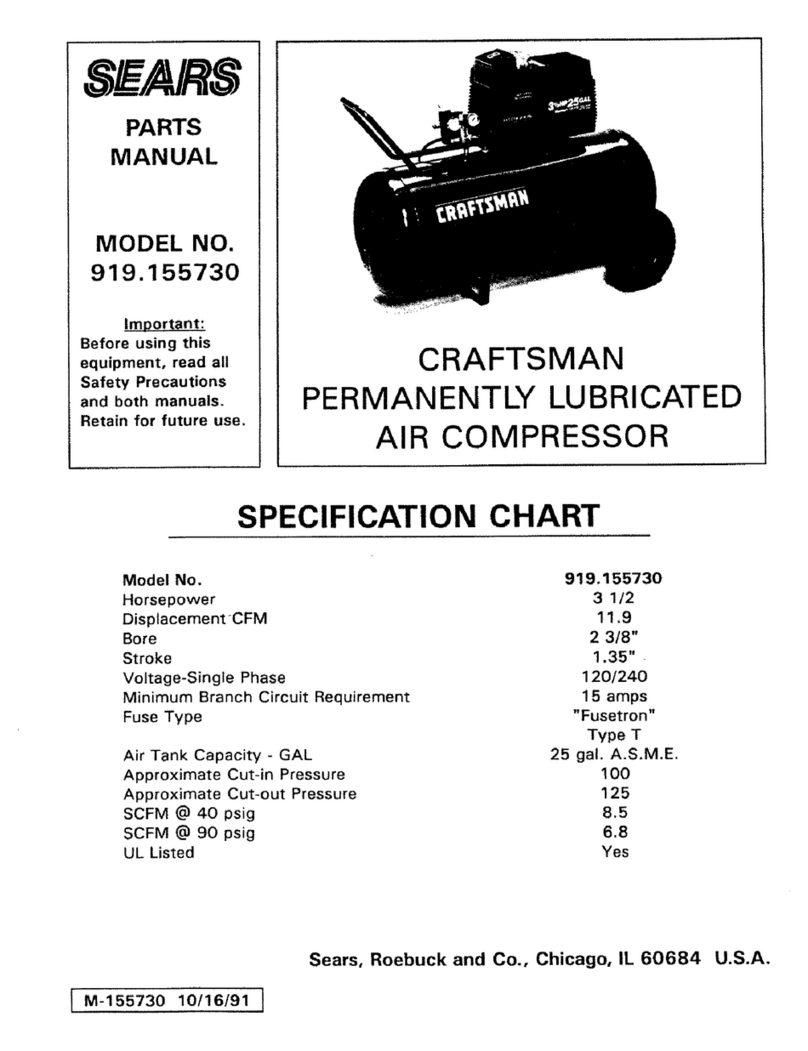

2 SPECIFICATIONS and ENVIRONMENTAL CONDITIONS

2.1 Specifications

Voltage/Frequency: ............................................................... 110-120/115-120VAC 50/60Hz, 7A

Voltage/Frequency (Optional): ........................................... 220-240/230-240VAC 50/60Hz, 3.5A

Pressure Output (maximum): .......................................................................................... 100 psiG

Ambient Pressure Frost Point: ......................................................................................... < -73 °C

Flow Rate (maximum): ..................................................................................................... 10 L/min

Sound Level: .................................................................................................................. <70 db(A)

Duty Cycle: ........................................................................................................................... 100%

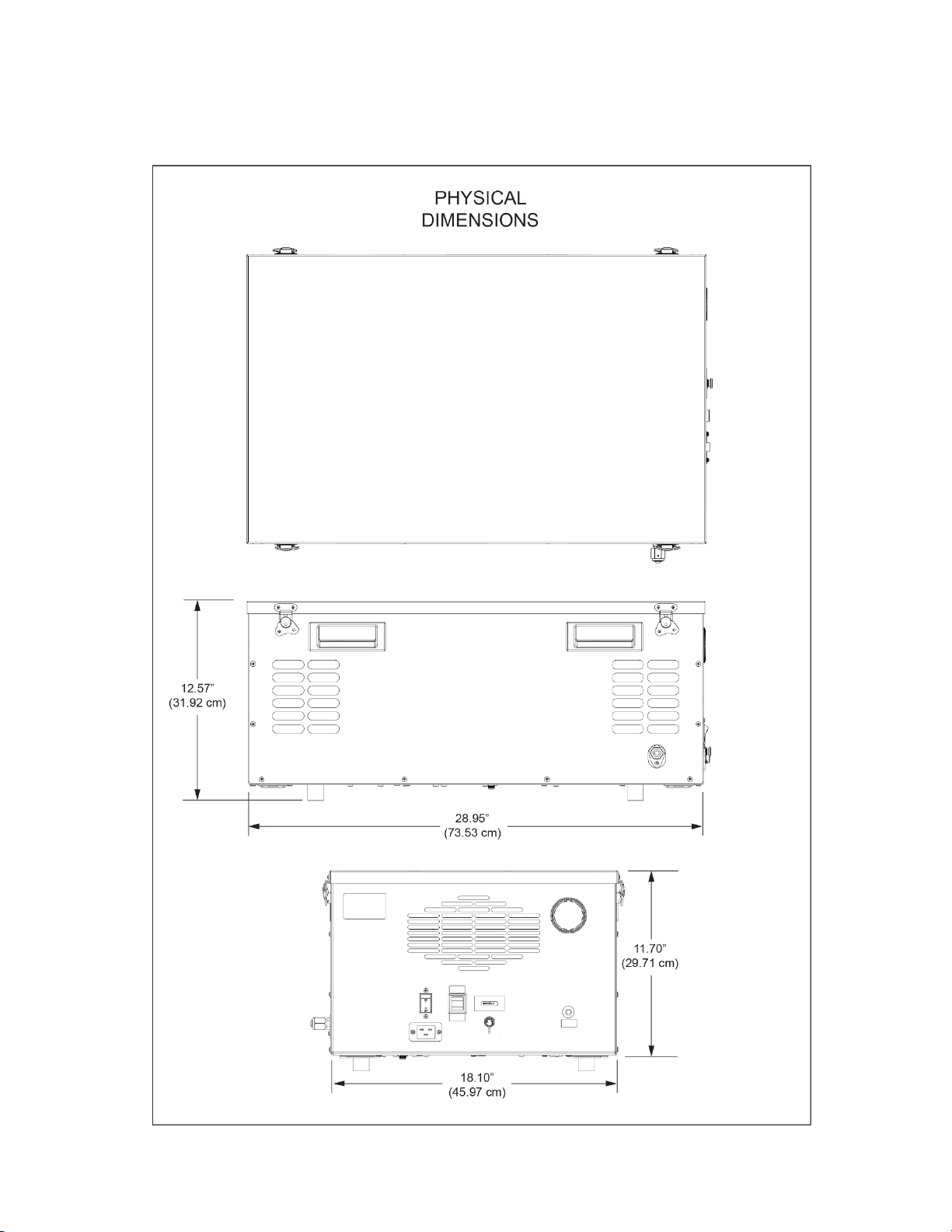

Physical Dimensions: ........................... 28.9 w" x 18.1 d" x 12.7 h" (73.4 cm x 46 cm x 32.2 cm)

Dry Weight: ........................................................................................................................ 75 lbs.

2.2 Environmental Conditions

Operating Temperature: .............................................................................................. 15 to 30 °C

Storage Temperature: ................................................................................................ > 0 to 50 °C

Humidity: .............................................................................................. 5 to 90% non-condensing

2.3 Warranty

Thunder Scientific Corporation (TSC) warrants this product to be free of defects in material and

workmanship under normal use and service when operated within the specified design limitations

for a period of 90 days from date of shipment or 2000 operating hours, whichever comes first.

TSC's obligation under this warranty shall be limited to the following: Product is returned to TSC

with transportation charges prepaid and that TSC's examination reveals the Product to be

defective, TSC, at its option, shall repair or replace at TSC's plant, any part or parts of the Product

which is or are defective. This warranty shall not apply to any Product that has become damaged

or inoperative because of ordinary wear, misuse, cold, heat, rain, excessive humidity, freeze

damage, use of improper chemicals, negligence, accident, failure to operate the product in

accordance with the instructions provided in the Operation and Maintenance Manual(s) supplied

with the product, improper maintenance, the use of accessories or attachments not

recommended by TSC or unauthorized repair or alterations.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER

WARRANTY, WHETHER EXPRESS OR IMPLIED, AND ALL OTHER LIABILITIES AND

OBLIGATIONS ON THE PART OF TSC; TSC SHALL NOT BE LIABLE FOR ANY INCIDENTAL,

INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT

FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT.