Date: 05.02.10

Subject to change in the interest

of technical progress.

OPERATING INSTRUCTIONS

Universal Thermostat

with modulating power control

© Paul Wärmerückgewinnung GmbH • August-Horch-Straße 7 • 08141 Reinsdorf • Deutschland

Tel:

+49(0)375-303505-0

•

Fax:

+49(0)3

75-303505-55

•

E-Ma

il: [email protected] • Internet: www.paul-lueftung.de

1

0. PREFACE

READ THESE INSTRUCTIONS CAREFULLY BEFORE USING THE EQUIPMENT!

This instruction contains all information necessary for an optimal installation, startup and. It can also be used

as a manual for maintenance and service work.

For the function and proper use of this device, all instructions in the assembly and operation instructions must

be followed strictly.

In case of disregarding these instructions, as well as the use of non-original parts, all warranty- and liability

claims are cancelled.

NOTE: This instruction has been made with greatest care. However, this introduction confers no

rights. We reserve the right to change all or part of the contents of this instruction without prior

notice. 1. Short description

The universal thermostat is used as a stand-alone control unit for the components brine defroster / GHX

regulating flap, defroster heater or electric backup duct heater. It has two programmable and independent

switching points (Temp 1 and Temp 2) with adjustable hysteresis.

The control for the electrical consumer is performed by an electronic relay, for electric duct heaters with

modulating power control. Pparallel to this a potential-free changeover is available. Enabling and locking of the

control can be performed by an external potential-free enabling contact. The programmed temperature values

as well as the temperature at the sensor are shown by a 7-segment display. Please see appendix 1: Electrical

connections / Terminal diagram.

2. Function / Operation

2.1 Operating modes

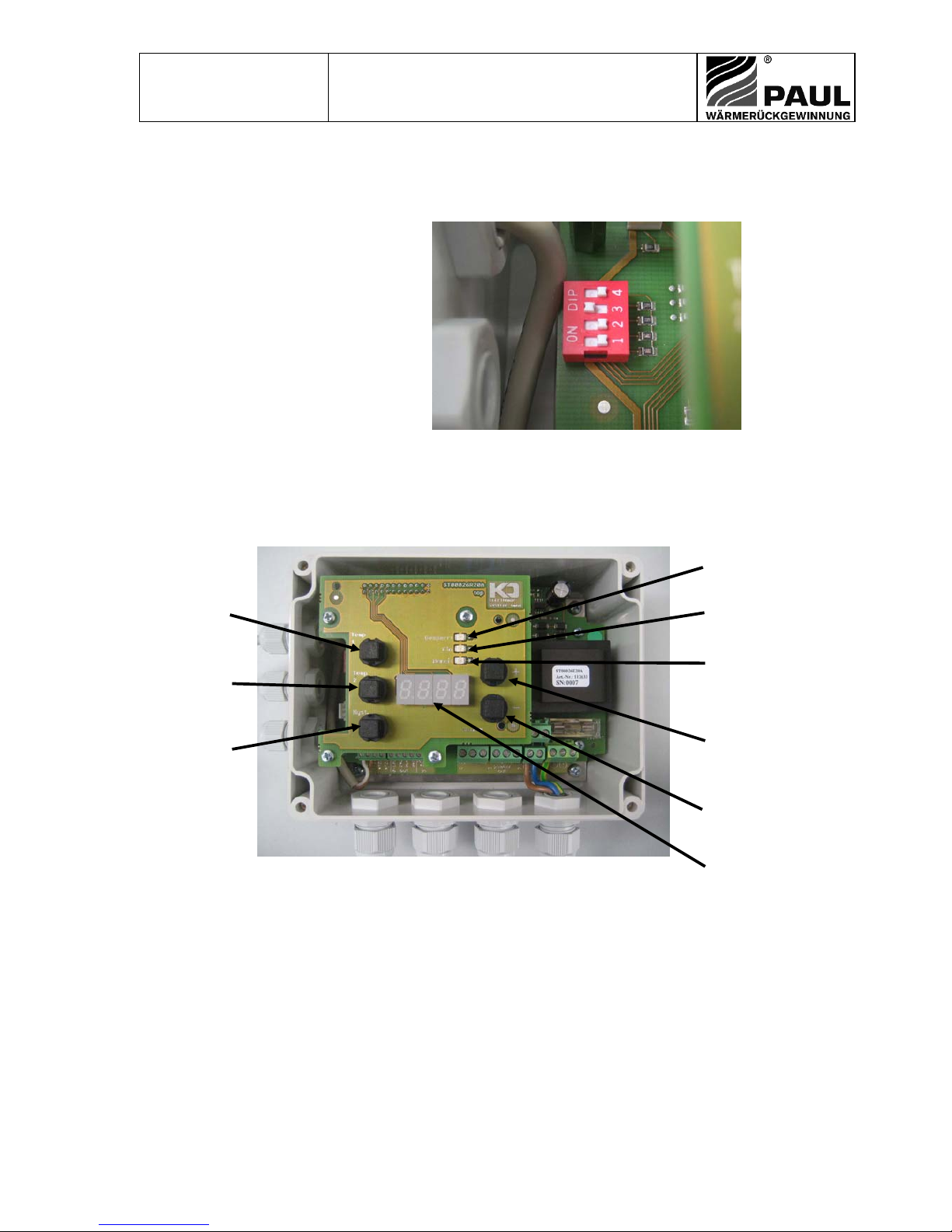

The configuration of the operating mode is done by DIP-switches. After selecting the new operating mode, the

control system has to be restarted (disconnection from supply).

2.1.1 Continuous control for heating elements (Defroster heater / Backup duct heater)

This operation mode is most suitable to achieve a constant air temperature even though the ambient

conditions are changing. The capacity of the heating element is modulated by the control system, so that

the temperature inside the air duct is always constant.

The temperature sensor is installed in the air duct (in air flow direction) downstream of the components

defroster heater / backup duct heater. The control of the brine defroster / GHX regulating flap depends on

the configured temperature threshold X1 (see appendix 1, appendix 3 and appendix 4):

ON: T ≤X1

OFF: T ≥X1+H

DIP-1, -2 ON

DIP-3, -4 OFF

T - Actual value of measured temperature depending on purpose:

- Intake air temperature downstream of defroster heater

- Supply air temperature downstream of backup duct heater

H - Hysteresis

X1 - Setpoint ″temperature switching threshold″

t- Cycle time pulse package control in seconds (s)