Page 4 of 12

Commissioning

Filling, Flushing and Commissioning of the Solar Station

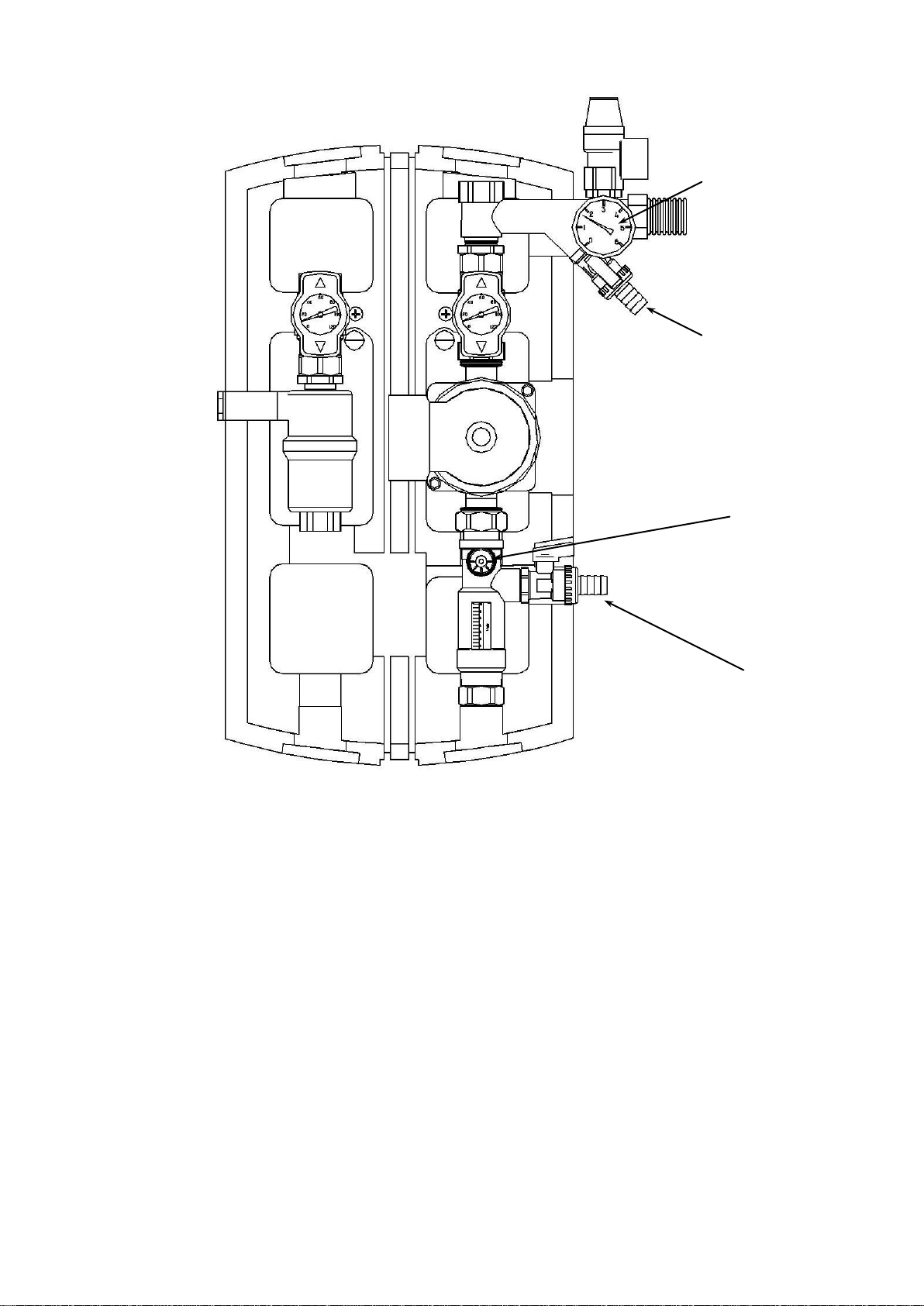

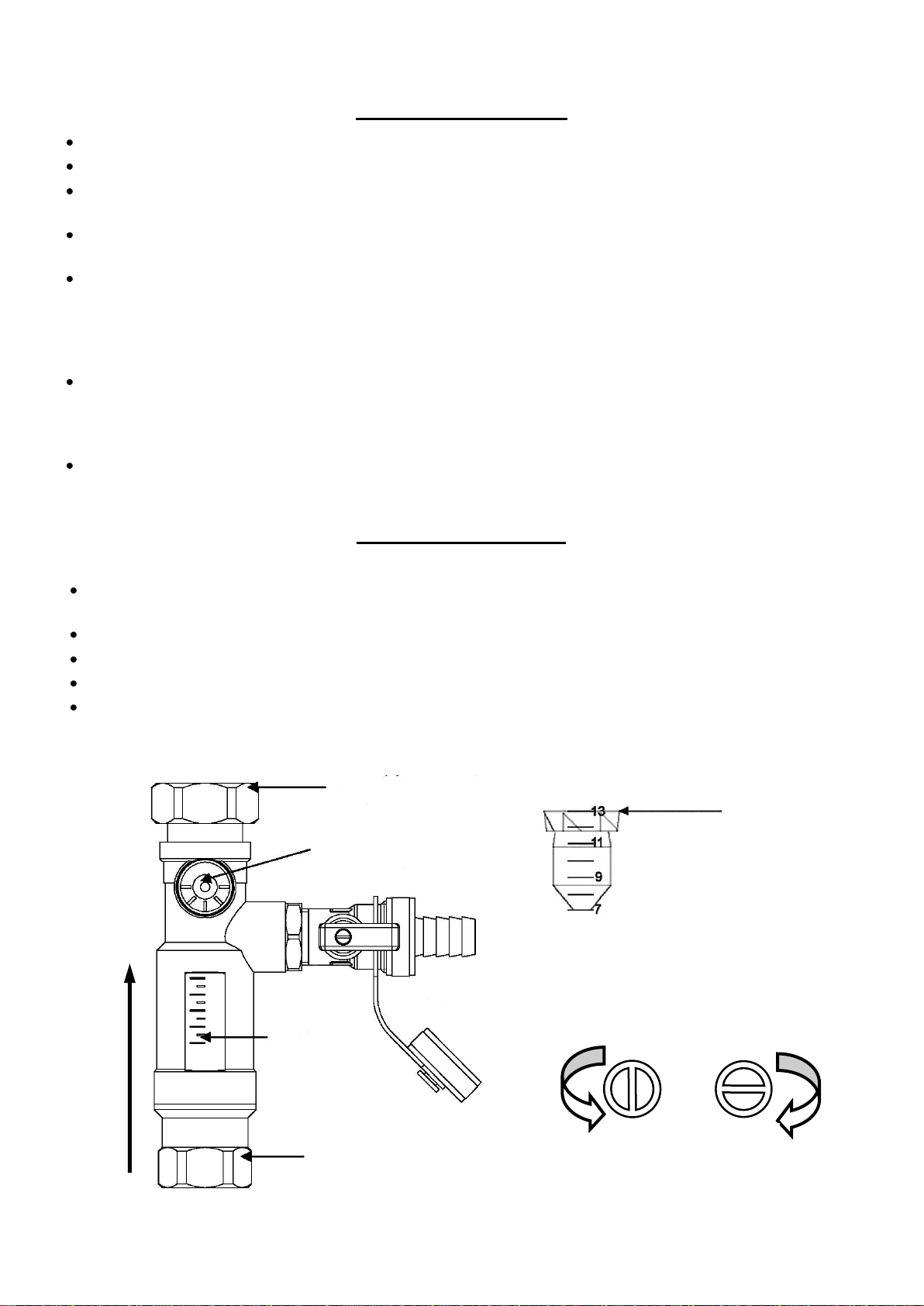

1. Connect the pressure hose to the fill valve (2) below the pressure gauge (1) and open the valve.

2. Connect the flush hose to the flush valve (4) on the flow meter (on the ball valve below the

pump) and open the valve.

3. The slot of the screw at the flow meter (3) has to be in a horizontal position. This way, the

integrated ball valve is closed (see user’s guide for the flow meter). Open both check valves

(over the pump and inside the supply valve); in order to do this, bring the ball valve into a 45°

position (half open, half closed) using 14 mm or 9/16 wrench.

4. Fill up solar fluid into the clean container and charge the solar loop using external service pump.

5. Flush the solar circuit for at least 15 min. In order to remove all of the air from the system, it is

necessary time to time to open the balancing screw on the flow meter.

6. Never flush or make a hydrostatic pressure test of the whole solar installation only

with water. It is impossible to completely empty the installation; there is a danger of

icing damages!

7. Close the flush valve (4) while the pump is still working and increase the pressure of the system

to approx. 5 bar/ 72 PSI. You can read the pressure from the pressure gauge (1).

8. Close the fill valve (2) and switch off the service pump. Open completely the balancing valve at

the flow meter (slot vertical).

9. Bleed the installation from above the collectors until the heat transfer fluid comes out free from

bubbles. If necessary, increase the pressure to approx. 5 bar/72 PSI and check for the leaks on

all the joints. If there is a considerable pressure drop on the pressure gauge (1), you can assume

that there is a leak in the system.

10. Adjust the operating pressure in accordance with the installation requirements (approx. 1,8

bar/28 PSI for a static height between the collectors and the pressure gauge of 5 m/16 ft; and

to 2,3 bar/33 PSI for a static height 10 m/32 ft).

11. Set the circulation pump on the highest speed level (see user’s guide of the pump and the

controller) and keep it circulating for at least 15 min. Adjust the circulation pump to the desired

RPM level.

12. Adjust the flow rate on the flow meter in accordance to collector manufacturer’s instructions.

13. Disconnect the hoses of the fill pump and cap the flush and fill valves with supplied cups.

14. Double check the possible leaks of the installation. Open both shut-off ball valves completely.

15. Fix the front shell of the solar station. Insert the red handle with thermometer in the supply line

(on the left side) and the blue handle with thermometer in the return line (on the right side).