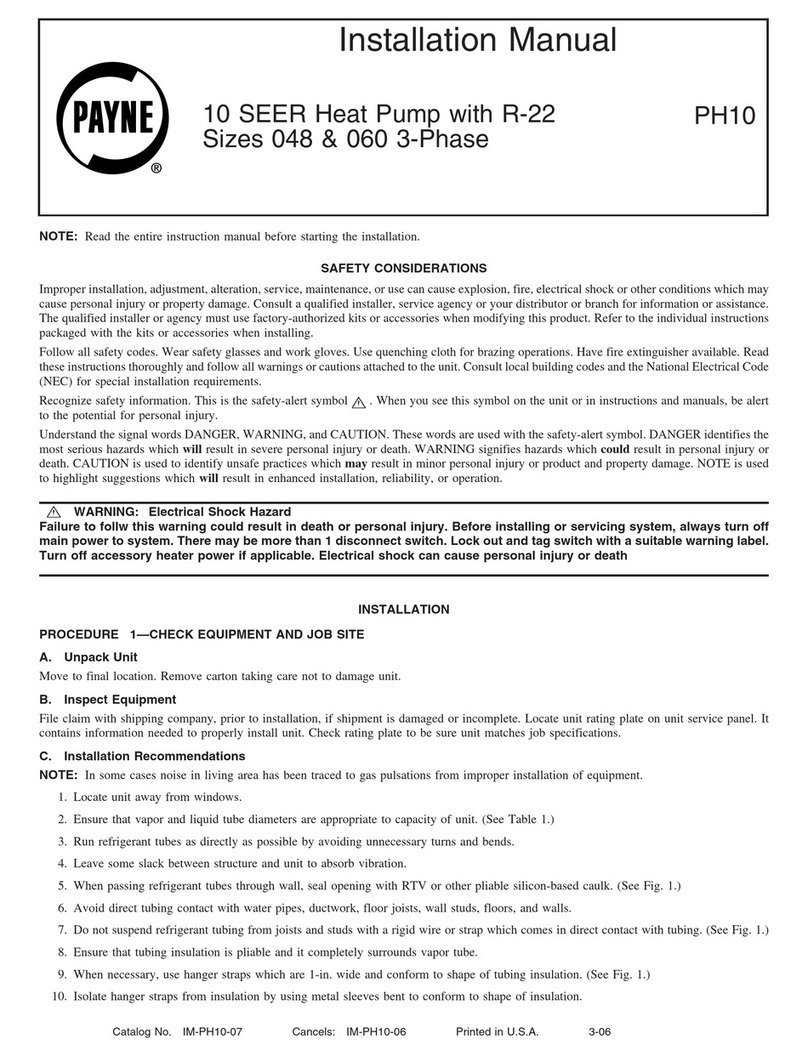

Wiring Diagram

PH14*B

SPLIT--SYSTEM HEAT PUMP

WITH R--410A REFRIGERANT

1--1/2 -- 5 NOMINAL TONS

CAP

H

F

C

339904-101 REV. C

CONDENSING UNIT CHARGING INSTRUCTIONS

For use with units using R-410A refrigerant

COOLING ONLY

CHARGING PROCEDURE

Where a dash (- -) appears do not attempt to charge system under these

conditions or refrigerant slugging may occur. Charge must be weighed in.

Note: Superheat ºF is at low-side service port, allow a tolerance of +/- 3 ºF

Note: Indoor dry bulb between 70 ºF and 80 ºF

* Optimum performance point, 82 ºF outdoor ambient and (80 ºF dry bulb),

(67 ºF wet bulb) indoor conditions. (DOE B Test Conditions)

TABLE I - SUPERHEAT CHARGING TABLE

(SUPERHEAT ºF AT LOW-SIDE SERVICE PORT)

OUTDOOR

TEMP ºF

EVAPORATOR ENTERING AIR º F WB.

67

50 52 54 56 58 60 62 64 68 70 72 74 76

55

60

65

70

75

82

85

90

95

100

105

110

115

11 11 12 12 12 13 17 20 24 24 25 25 25 25

6677712

16 21 22

723 23 23 23

3712

18 19 21 21 22 22

- - - - - - - - - -

714

16 18 20 20 20

- - - - - - - - - -

- - - - - -

- - - -

- - - - - - - - 311 13 16 18 18 19

- - - - - - --------

- - - - - - - - - - - -

- - 6812 15 16 17

47

11 14 15 16

4812 14 15

61012 14

4811 12

369

11

5710

863

- - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - -

- - - - - -

- - - -

- - - -

- - - -

- -

*

TABLE II - REQUIRED SUCTION TUBE TEMPERATURE ºF

(MEASURED AT LOW-SIDE SERVICE PORT)

SUCTION PRESSURE AT SERVICE PORT PSIG.

108 112 117

121 126 131 139 141 146

SUPERHEAT

TEMP. ºF

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

35 37 39 41 43 45 47 49 51

37 39 41 43 45 47 49 51 53

39 41 43 45 47 49 51 53 55

41 43 45 47 49 51 53 55 57

43 45 47 49 51 53 55 57 59

45 47 49 51 53 55 57 59 61

47 49 51 53 55 57 59 61 63

49 51 53 55 57 59 61 63 65

51 53 55 57 59 61 63 65 67

53 55 57 59 61 63 65 67 69

55 57 59 61 63 65 67 69 71

57 59 61 63 65 67 69 71 73

59 61 63 65 67 69 71 73 75

61 63 65 67 69 71 73 75 77

63 65 67 69 71 73 75 77 79

65 67 69 71 73 75 77 79 81

* MAY BE FACTORY OR FIELD INSTALLED

-LEGEND-

CONNECTION DIAGRAM

FIELD SELECTED TIME PERIOD

BETWEEN DEFROST CYCLES (MINUTES)

JUMPERED TEST PINS (USE METAL OBJECT), FIELD SPEED-UP CYCLE

HEAT CYCLE: 90 MIN. ACCELERATED TO 21 SEC.

60 MIN. ACCELERATED TO 14 SEC.

30 MIN. ACCELERATED TO 7 SEC.

10 MIN. ACCELERATED TO 2 SEC.

DEFROST CYCLE:

90

60

30

SPEED

UP

SCHEMATIC DIAGRAM (LADDER FORM)

CAP

*CH

*CHS

COMP

CONT

CB

DFT

DR

*DTS

*HPS

*LLS

*LPS

OFM

RVS

*SC

*SR

*ST

CAPACITOR

CRANKCASE HEATER

CRANKCASE HEATER SWITCH

COMPRESSOR

CONTACTOR

CIRCUITBOARD

DEFROSTTHERMOSTAT

DEFROSTRELAY & CIRCUITRY

DISCHARGE TEMP. SWITCH

HIGH PRESSURE SWITCH

LIQUID LINE SOLENOID VALVE

LOW PRESSURE SWITCH

OUTDOOR FAN MOTOR

REVERSING VALVE SOLENOID

STARTCAPACITOR

STARTRELAY

STARTTHERMISTOR

1. Compressor and fan motor furnished with

inherent thermal protection.

2. To be wired in accordance with National

Electric Code (N.E.C.) and local codes.

3. N.E.C. class 2, 24V circuit, min. 40 VA required,

60 VA on units installed with LLS.

4. Use copper conductors only, from disconnect to unit.

5. Must use thermostat and sub-base as stated

in pre-sale literature.

6. If indoor section has a transformer with a

grounded secondary, connect the grounded

side to "C" on the circuit board.

7. If any of the original wire, as supplied, must

be replaced, use the same or equivalent wire.

8. Check all electrical connections inside control

box for tightness.

9. Do not attempt to operate unit until service

valves have been opened.

10. Use conductors suitable for at least 75ºC (167ºF).

NOTES:

CAUTION

1. Compressor damage may occur if system is

over charged.

2. This unit is factory charged with R-410A in

accordance with the amount shown on the rating

plate. The charge is adequate for most systems

using matched coils and tubing not over 15 feet

long. Check refrigerant charge for maximum

efficiency. See Product Data Literature for

required Indoor air Flow Rates and for use of

line lengths over 15 feet.

3. Relieve pressure and recover all refrigerant

before system repair or final disposal. Use all

service ports and open all flow-control devices,

including solenoid valves.

4. Never vent refrigerant to atmosphere.

Use approved recovery equipment.

1. Operate unit a minimum of 10 minutes

before checking charge.

2. Measure suction pressure by attaching

an accurate gage to suction valve

service port.

3. Measure suction temperature by

attaching an accurate thermistor type

or electronic thermometer to the

suction line at service valve.

4. Measure outdoor air dry-bulb

temperature with a thermometer.

5. Measure indoor air (entering indoor

coil) wet-bulb temperature with a sling

psychrometer.

6. Refer to Table I. Find outdoor

temperature and evaporator entering

air wet-bulb temperature. At this

intersection, note superheat. Where a

dash (- -) appears on table do not

attempt to charge system under these

conditions or refrigerant slugging may

occur. Charge must be weighed in,

adding or removing 0.6 oz/ft of 3/8

liquid line above or below 15 ft.

respectively.

7. Refer to Table II. Find superheat

temperature located in step 6 and

suction pressure. At this intersection

note suction line temperature.

8. If unit has a higher suction line

temperature than charted temperature,

add refrigerant until charted

temperature is reached.

9. If unit has a lower suction line

temperature than charted temperature,

remove and recover refrigerant until

charted temperature is reached.

10. When adding refrigerant, charge in

liquid form into the suction service port

using a flow-restricting device.

11. If outdoor air temperature or pressure

at suction valve changes, charge to

new suction line temperature indicated

on chart.

12. This procedure is valid when indoor air

flow is within +/- 21% of its rated cfm

FACTORY POWER WIRING

FIELD POWER WIRING

FACTORYCONTROLWIRING

FIELD CONTROL WIRING

CONDUCTOR ON CIRCUIT BOARD

COMPONENTCONNECTION

1/4-IN QUICK CONNECT TERMINALS

FIELD SPLICE

JUNCTION

C

RVS

OO

W2

RR

Y

Y

C

DFT

DFT

DR

T1 C

LOGIC

DR

OF1 OF2

L2

L1

COMP

OFM

CAP

*SC

1

2

5

*SR

*S

T

+t°

S

CR

*H

PS

*LP

S

*D

TS

EQUIP

GND

CONT

* CHS

* CH

11 21

CONT

CONT

23 23

*LPS

*HPS

YEL/PNK BLU/PNK

*DTS

208/230 1Ø

POWER

SUPPLY

EQUIP GND

L1

L2

BLK

YEL YEL

OFM

*CH

COMP

BLK

BLK

BLK

*CHS

BLK

or

RED

BLK

RED or BLK

BLK

BLU

BRN

YEL

YEL

S

C

R

*SC *ST

BRN

BLU

BLU

*SR

+t°

12

5

RVS

DFT

PNK

YEL/PNK

BRN

YEL

ORN

ORN

BRN YEL

CONT

11 21

23

23

GLER

W2

OYC

INDOOR UNIT

TERMINAL BLOCK

ORN

G

W3

LER

W2

OYC

INDOOR

THERMOSTAT

(NOTE #5)

BLK

OF1

OF2

CO

WHT

W2

RED

R

Y

T1

R

C

C

DFT

O

YEL

YPNK

BLU/PNK

90

30 60 W1

SPEED UP

RED

OR

BLUE

RED

OR

BLUE

YEL

H

F

C

Fig. 1 – Wiring Diagram — Model sizes 1--1/2 -- 4 tons, 208/230--1