PBI Dansensor SGI-3 User manual

O N T H E Q U A L I T Y L I N E

SGI-3/OXI-3/OXI-3.1

User manual

English

PBI-210247-HUK 07/11/2005

Oxygen indicator

SGI-3

OXI-3

OXI-3.1

User manual

PBI-Dansensor A/S

Your local distributor

Copyright ©PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005

PBI-Dansensor A/S •Roennedevej 18 • 4100 Ringsted • Denmark • Tel.: +45 57 66 00 88

Fax: +45 57 66 00 99 • e-mail: [email protected] • Website: www.pbi-dansensor.com

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

Contents

239.10. 3. OXI-3.1 ..............................................

239.10. 2. OXI-3 ................................................

239.10. 1. SGI-3 ................................................

239.10. Mechanical data ............................................

239.9. Acceptable ambient temperature, etc. ..........................

239.8. Operating voltage ............................................

229.7. Indication, SGI-3 & OXI-3 .....................................

229.6. Measuring accuracy ..........................................

229.5. Response time ..............................................

229.4. Flow system, OXI-3.1 ........................................

229.3. Flow system, SGI-3 & OXI-3 ..................................

219.2. Measuring range .............................................

219.1. Sensor .....................................................

21

9. Technical specifications ........................................

208.4. Spare parts for OXI-3.1 .......................................

208.3. Consumables for SGI-3 and OXI-3 .............................

198.2. Spare parts for SGI-3 and OXI-3 ...............................

198.1. Accessories for SGI-3 and OXI-3 ..............................

19

8. Spare parts and accessories ....................................

17

7. Error messages/ Troubleshooting ...............................

166.4. Cleaning ....................................................

156.3. Calibration procedure for OXI-3.1 ..............................

146.2. Calibration procedure for OXI-3 ................................

136.1. Calibration procedure for SGI-3 ................................

13

6. Maintenance ...................................................

125.4. Voltage and current output ....................................

115.3. OXI-3.1 pin connections ......................................

115.2. OXI-3 pin connections ........................................

115.1. SGI-3 pin connections ........................................

11

5. Input/output signals ............................................

104.4. Shielding gas tools ...........................................

104.3. Material corrosion resistance ..................................

104.2. Shielding gas measuring ......................................

104.1. Measuring errors in connection with welding .....................

10

4. Welding (SGI-3) .................................................

93.5. Shutdown ....................................................

93.4. Alarm (SGI-3 and OXI-3 only) ..................................

93.3. Measurement ................................................

83.2. Connection of measuring gas ...................................

83.1. Start-up .....................................................

8

3. Connection of the SGI-3, OXI-3 and OXI-3.1 ........................

72.1. Recommendations ............................................

7

2. Safety precautions ...............................................

4

1. Introduction .....................................................

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 3

1. Introduction

The SGI-3 is PBI-Dansensor’s portable oxygen indicator for measurement of O2levels,

especially in connection with shielded arc welding.

The SGI-3 was designed to measure the oxygen level in all sorts of welding gases, both

pure gases and formier gases.

The built-in measuring gas pump ensures that gas is supplied to the oxygen indicator from

the measuring point, and a row of LEDs indicate the value measured. The more LEDs lit,

the lower the oxygen level at the measuring point. The measuring range for pure gases is

between 5000 ppm (0.5%) to 1 ppm oxygen in inert welding gases and between 500-10

ppm for formier gases.

The oxygen sensor is a zirconium oxide sensor developed by PBI-Dansensor, which

makes it possible to measure the very low oxygen levels (below 30 ppm) required in order

to ensure high-quality welding.

In addition, the oxygen indicator has an output for data collection. This facility allows

automatic documentation of the quality of each individual weld.

A programmable acoustic alarm function makes it possible to perform welds within the

required oxygen range without having to read the indicator while welding.

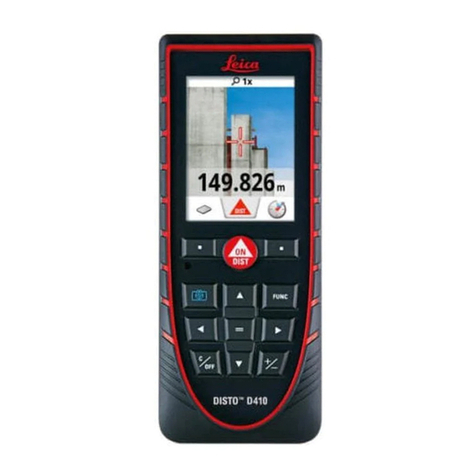

Figure 1. SGI-3

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

4 PBI-210247-H UK 07/11/2005

The OXI-3 is PBI-Dansensor’s portable oxygen indicator for measurement of the O2level

in various industrial applications. This indicator is very similar to the SGI-3, but the

following should be noted:

There are 2 measuring ranges: 20.9% to 0.1% O2 and 1000 to 1 ppm O2.

This oxygen analyzer cannot be used for measuring in formier gases.

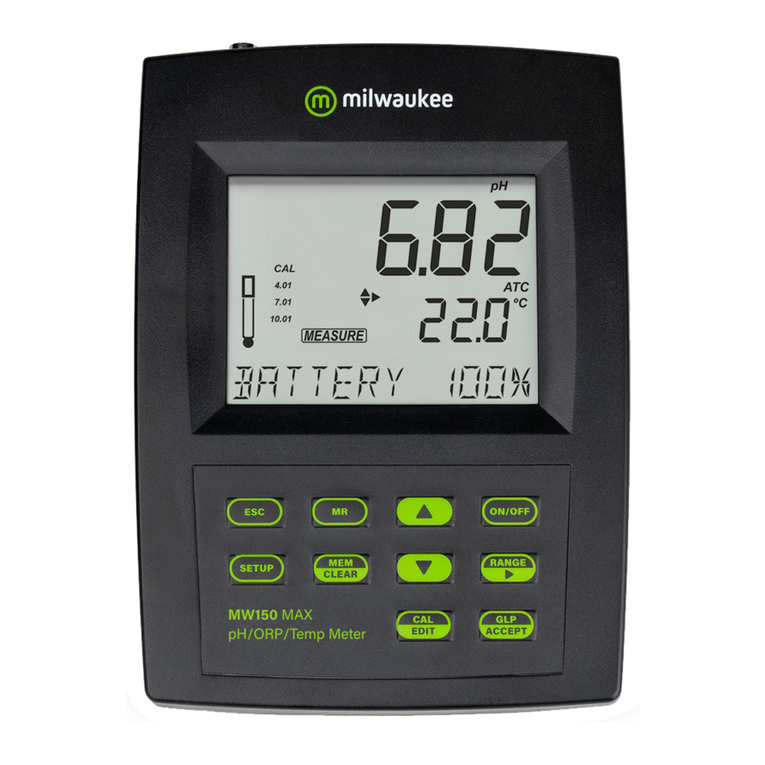

Figure 2. OXI-3

The OXI-3.1 is largely identical with the OXI-3, but it has no oxygen indicator scale and

is therefore mainly intended for online measurements where the linearized voltage output

can be used for control purposes.

There are 3 versions of OXI-3.1 with the following measuring ranges:

0%-100% O2and 0-1000ppm O2

0%-2% O2and 0-1000ppm O2

0%-8% O2and 0-1000ppm O2

Figure 3. OXI-3.1

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 5

2. Safety precautions

Read and understand this manual for the sake of your own safety and the quality of the

work that you perform using this equipment.

The following concepts are used in this manual:

"DANGER" Indicates a condition that MAY cause danger to life or serious

physical injury.

"WARNING" Indicates a condition that MAY cause serious physical injury or

damage to the equipment in question.

"NOTE" Indicates a condition that MAY cause equipment misoperation,

leading to erroneous measuring results.

Follow these instructions carefully:

DANGER: Opening the device may involve danger to life or serious injury.

Live high-voltage wires may be exposed.

When connecting to mains, the unit must be connected to earth.

Under certain circumstances, mixture ratios with a

hydrogen (H2 hydrogen) content exceeding 6% can be

explosive in combination with atmospheric air.

WARNING: Always use correct fittings and hoses for gas connections.

Always use correct tools, and keep the gas inlet/outlet in

position when mounting/dismounting the hose connection and

nipples/sleeves.

When relocating/transporting the device it must not be subjected

to shocks.

The device must always be returned in the original transport

container for repair work covered by the guarantee.

The SGI-3/OXI-3 and the OXI-3.1 must never be used without

the measuring gas filter when measuring impure gases.

If the instructions above are not observed, the guarantee does

not apply.

The SGI-3 and the OXI-3 must never be exposed to direct gas

pressure, as the gas flow is controlled by the built-in pump.

NOTE: The OXI-3.1 was designed to measure oxygen in inert gases

online, where visual display is not required and where the output

signal is linear.

2.1. Recommendations

vWe recommend constant mains supply to avoid delay time when warming up. The

device was designed to be constantly connected to mains, and this does not impair

its service life.

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

6 PBI-210247-H UK 07/11/2005

3. Connection of the SGI-3, OXI-3 and OXI-3.1

3.1. Start-up

Connect the device to a 230 VAC (115 VAC) grounded power outlet using the supplied

mains cable.

When voltage is connected, the green “Power” LED lights up.

After a warm-up period of approx. 20 minutes, the green “Ready” LED will light up. The

device is now ready for use.

If the device is disconnected briefly, the subsequent warm-up period will be substantially

shorter (but not less than 3 minutes).

3.2. Connection of measuring gas

It is important to ensure that the measuring system is tight and to use oxygen

diffusion-proof hoses and fittings.

Not all hose materials are well suited. We recommend the use of the PBI-Dansensor A/S

measuring gas hose and the special shielding gas hose with accessory fittings.

Connect the measuring gas to the upper screwed connection ("GAS IN"). It is important to

use PBI-Dansensor A/S oxygen diffusion-proof hoses and to tighten the union carefully.

Use the "RANGE" push-button (SGI-3 and OXI-3 only) to select the gas to measure:

SGI-3: "Inert", "Formier 10 %", "Formier 5 %" and "Formier 2 %".

OXI-3: "%" and "ppm"

OXI-3.1: "%" and "ppm" (selected by means of external control voltage via

connector)

"%" used for inert gases in the percentage range.

"ppm" used for inert gases in the ppm range.

"Inert" used for inert gases such as argon (Ar),

nitrogen (N2), carbon dioxide (CO2), helium (He), and

mixed gases consisting of these constituents and oxygen (O2).

"Formier 10 %" used for gases with a reducing effect, such as

formier gas containing hydrogen (H2) 10% H2that is mixed

with either nitrogen (N2) or argon (Ar).

"Formier 5 %" used for a corresponding hydrogen mixture of 5 % H2.

"Formier 2 %" used for a corresponding hydrogen mixture of 2 % H2.

When measuring formier gas mixtures with other concentration levels, select the

measuring range closest to the gas concentration.

Danger: Under certain circumstances, mixture ratios with a hydrogen (H2 hydrogen)

content exceeding 6% can be explosive in combination with atmospheric air.

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 7

Always fit a pre-filter when using the oxygen indicator for welding and in dusty

environments; see the section “Spare parts and accessories” on page 18.

The use of a pre-filter will increase the reaction time before the correct indication can be

read.

3.3. Measurement

SGI-3 and OXI-3:

Gas values are measured by turning on the built-in pump. Start and stop the pump by

pressing the "PUMP" button or by means of an external control signal via the DIN

connector on the front plate. The on/off state of the pump is automatically stored, if the

supply voltage is cut off.

Warning: SGI-3 and OXI-3 must never be exposed to direct gas pressure, as the gas flow

is controlled by the built-in pump.

OXI-3.1:

When the OXI-3.1 is connected to mains, it will be ready to measure after the warm-up

period, when the “READY” LED is constantly lit. The OXI-3.1 has no pump, and

therefore it measures continuously when the measuring gas is forced through the gas inlet.

3.4. Alarm (SGI-3 and OXI-3 only)

The device has a built-in alarm function that goes off in case of excessive oxygen

concentration.

The alarm function is not available until the device is ready for use (“Ready” is lit).

The alarm can be activated or deactivated manually by briefly pressing both alarm buttons

(and) at the same time.

If the oxygen level exceeds the selected alarm limit, the alarm is automatically activated.

When the alarm is activated, the "Alarm" LED is lit, the row of LEDs flashes, and an

acoustic alarm is sounded.

Interrupt the acoustic alarm by pressing one of the alarm buttons. If a new alarm is

triggered, the acoustic alarm is activated again.

The alarm limit can be displayed in the row of LEDs by pressing one of the two alarm

buttons. A flashing LED indicates the maximum “permissible” oxygen level for 3 sec.

The alarm limit can be adjusted by pressing and holding both alarm buttons (and) for

3 sec. The green "Alarm" LED will now flash, and the alarm limit appears from the row of

red LEDs. Press orto lower or increase the setting. The new setting is automatically

stored after 3 seconds or if both alarm buttons are pressed at the same time, and the SGI-3

/ OXI-3 returns to normal mode.

The device can be fitted with an extra powerful internal acoustic alarm (accessory).

3.5. Shutdown

When measuring is complete, the pump can be stopped (SGI-3 and OXI-3 only).

Do not disconnect the supply voltage, if you intend to use the oxygen indicator again

within the next few hours.

When shutting down the device, please note that it is sensitive to shocks, particularly

when hot. We recommend that you let the oxygen indicator cool off completely (approx.

20 minutes) before packing it into a transport container.

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

8 PBI-210247-H UK 07/11/2005

4. Welding (SGI-3)

4.1. Measuring errors in connection with welding

Examples of measuring errors in connection with welding include:

vLeak in fittings or weld groove.

vOxygen diffusion-proof hoses have not been used.

vDefective membrane in shielding gas tool.

vWeld groove too large and/or skew.

vInsufficient shielding gas flow - failure to flush area clean.

vExcessive shielding gas flow - injector effect created, so that - for instance - air is

sucked into the weld groove.

4.2. Shielding gas measuring

In connection with shielding gas measuring we recommend the use of PBI-Dansensor’s

original groove probe (accessory), if the shielding gas tool does not have separate

measuring gas hose fittings.

4.3. Material corrosion resistance

To ensure maximum corrosion resistance in 18/8 steel (AISI 304) the oxygen content must

be below approx. 30 ppm during welding. However, an oxygen content of approx. 50 ppm

is permissible for acid-proof steel (AISI 316).

4.4. Shielding gas tools

The need to use shielding gas tools depends on the task in question.

The use of shielding gas tools is not in itself any guarantee of high-quality welding. This

sort of guarantee can only be achieved in connection with oxygen measurement and

control.

There are several commercially available shielding gas tools, each of which has its

particular advantages. However, there are also many "home made" tools, which fully meet

the demands of the user.

A good shielding gas tool meets the following demands:

vLow purchase price and maintenance costs.

vEquipped with fittings for connection of measuring gas hose.

vEasy to mount and dismount after welding.

vGood flow conditions, gas inlet from both sides and measuring outlet right below

the weld groove.

vProtected against pressure rise as the groove closes during welding.

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 9

5. Input/output signals

The SGI-3, OXI-3 and OXI-3.1 are equipped with an 8-pole DIN connector for connection

to data collection equipment and/or remote control.

Location of pins in the DIN connector seen from the soldering side.

Note: The functions of this connector have been changed in relation to previous

models in some respects.

5.1. SGI-3 pin connections

pin 1 (+) & pin 2 (-) : Current output - see also the section “Measuring range” on

page 20.

pin 3 (+) & pin 2 (-) : “Ready” output:

vsensor cold (not ready) = 0 VDC

vsensor warm (ready to measure) = 15 VDC (100mA)

pin 4 (+) & pin 7 (-) : “Start measuring” input:

vStop measuring = 0 VDC

vStart measuring = 10-32 VDC (10 mA)

pin 6 (+) & pin 5 (-) : 15 VDC supply output, max. 10 mA

pin 5 (-) : Internally connected to pin 2 (-)

pin 8 (+): Internally connected to pin 1 (+)

5.2. OXI-3 pin connections

pin 1 (+) & pin 2 (-) : Current output - see also the section “Measuring range” on

page 20.

pin 3 (+) & pin 2 (-) : “Ready” output:

vsensor cold (not ready) = 0 VDC

vsensor warm (ready to measure) = 15 VDC (100mA)

pin 4 (+) & pin 7 (-) : “Start measuring” input:

vStop measuring = 0 VDC

vStart measuring = 10-32 VDC (10 mA)

pin 6 (+) & pin 5 (-) : “Measuring range” output:

v“%” measuring range = 0 VDC

v“ppm” measuring range = 15 VDC (100mA)

pin 5 (-) : Internally connected to pin 2 (-)

pin 8 (+): Internally connected to pin 1 (+)

5.3. OXI-3.1 pin connections

pin 1 (+) & pin 2 (-) : Voltage output - see also section “Measuring range” on page

20.

pin 3 (+) & pin 2 (-) : “Ready” output:

vsensor cold (not ready) = 0 VDC

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

10 PBI-210247-H UK 07/11/2005

68

3

5

2

4

1

7

vsensor warm (ready to measure) = 15 VDC (10 mA)

pin 4 (+) & pin 7 (-) : “Measuring range” input:

v“ppm” measuring range = 0 VDC

v“%” measuring range = 10-32 VDC (10 mA)

pin 6 (+) & pin 5 (-) : 15 VDC supply output, max. 10 mA

pin 5 (-) : Internally connected to pin 2 (-)

pin 8 (+): Internally connected to pin 1 (+)

5.4. Voltage and current output

Jumper “JM3” (the upper jumper in the small PCB) determines whether the output (pin 1

& pin 2) in the DIN connector is a current output or a voltage output.

vJM3 in pos. 1-2 = Current output (max. 500 Ohm)

vJM3 in pos. 2-3 = Voltage output (0 - 5 VDC)

The factory setting is normally current output on SGI-3 and OXI-3, and voltage output on

OXI-3.1.

Warning: It is important that the connection between the device and the printer or other

data collection equipment is made correctly.

When using the current output to supply peripheral equipment, only pin 1 (or 8) and pin 2

(or 5) should be connected.

Connected equipment must be galvanically separated from mains (and ground), and it

must not send voltage back to the output of the device.

When welding:

Use a screened cable between the oxygen indicator and the connected equipment. The

screen should only be connected to the housing of the DIN connector linked to the

oxygen indicator.

The cable between the device and the printer must be connected before mains voltage is

supplied.

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 11

6. Maintenance

Although the PBI-Dansensor A/S Oxygen Indicator is very reliable and stable‚ there may

be situations when the information displayed is not correct for some reason.

Later in this manual you will find a trouble-shooting chart with typical fault diagnoses,

most frequent causes, and solutions to the fault in question.

6.1. Calibration procedure for SGI-3

Calibration

Warm up SGI-3 for at least 4 hours.

Normally, 6 calibrations must be carried out, 4 of which with gases, typically: 1000ppm

O2, 25ppm O2, 500ppm O2in 10% H2formier gas and 50ppm O2in 10% H2formier gas.

Supply the calibration gas via an overflow device with a flow rate of at least 0.5 l/min, and

wait until the readings are quite steady.

1. Activate the calibration menu by pressing the “RANGE” button and the two alarm

buttons ( ) for 3 seconds.

2. The calibration menu now allows you to select the required calibration by pressing the

“RANGE” button.

Cal. 1 : Offset calibration of the current output.

The “Alarm” LED flashes, and the first red LED is lit. Connect an ammeter to the DIN

connector, pin 1 (+) and pin 2 (-). Set the current output at 4mA by means of the “alarm

up” or the “alarm down” button. This setting is independent from the gas input. Save

the calibration by pressing both “alarm up” and “alarm down” at the same time.

Cal. 2 : Gain calibration of the current output.

The “Alarm” LED is constantly lit, and all 48 red LEDs are lit. Connect an ammeter to

the DIN connector, pin 1 (+) and pin 2 (-). Set the current output at 20mA by means of

the “alarm up” or the “alarm down” button. This setting is independent from the gas

input. Save the calibration by pressing both “alarm up” and “alarm down” at the same

time.

Cal. 3 : 1st calibration of inert gases.

The “Inert” LED flashes. Select an oxygen concentration that corresponds to the

highest ppm value used, and let the system flush through until a steady readout is

achieved (at least 2 min.). Adjust the number of LEDs that should be lit using the

“alarm up” or the “alarm down” button. Save the calibration by pressing both “alarm

up” and “alarm down” at the same time.

Cal. 4 : 2nd calibration of inert gases.

The “Inert” LED is lit. Select an oxygen concentration that corresponds to the lowest

ppm value used, and let the system flush through until a steady readout is achieved (at

least 2 min.). Adjust the number of LEDs that should be lit using the “alarm up” or the

“alarm down” button. Save the calibration by pressing both “alarm up” and “alarm

down” at the same time.

Cal. 5 : 1st calibration of formier gases.

The “Formier 10%” LED flashes. Select a formier gas that corresponds to the highest

ppm value used, and let the system flush through until a steady readout is achieved (at

least 3 min.). Adjust the number of LEDs that should be lit using the “alarm up” or the

“alarm down” button. Save the calibration by pressing both “alarm up” and “alarm

down” at the same time.

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

12 PBI-210247-H UK 07/11/2005

Cal. 6 : 2nd calibration of formier gases.

The “Formier 10%” LED is lit. Select a formier gas that corresponds to the lowest ppm

value used, and let the system flush through until a steady readout is achieved (at least

3 min.). Adjust the number of LEDs that should be lit using the “alarm up” or the

“alarm down” button. Save the calibration by pressing both “alarm up” and “alarm

down” at the same time.

When saving a calibration you leave the calibration menu.

To leave the calibration menu without saving a calibration, turn off the SGI-3. Formier

gases with 5% and 2% hydrogen should not be calibrated, as they are calculated on the

basis of the calibration using 10% hydrogen.

6.2. Calibration procedure for OXI-3

Calibration

Warm up OXI-3 for at least 4 hours.

Normally, 6 calibrations must be carried out, 3 of which with gases, typically: 20.9 % O2

(atmospheric air), 0.1% (1000ppm) O2, and 25ppm O2.

Supply the calibration gas via an overflow device with a flow rate of at least 0.5 l/min, and

wait until the readings are quite steady.

Carry out a total of 6 calibrations.

1. Activate the calibration menu by pressing the “RANGE” button and the two alarm

buttons ( ) for 3 seconds.

2. The calibration menu now allows you to select the required calibration by pressing the

“RANGE” button.

Cal. 1 : Offset calibration of the current output.

The “Alarm” LED flashes, and the first red LED is lit. Connect an ammeter to the DIN

connector, pin 1 (+) and pin 2 (-). Set the current output at 4mA by means of the “alarm

up” or the “alarm down” button. This setting is independent from the gas input. Save

the calibration by pressing both “alarm up” and “alarm down” at the same time.

Cal. 2 : Gain calibration of the current output.

The “Alarm” LED is constantly lit, and all 48 red LEDs are lit. Connect an ammeter to

the DIN connector, pin 1 (+) and pin 2 (-). Set the current output at 20mA by means of

the “alarm up” or the “alarm down” button. This setting is independent from the gas

input. Save the calibration by pressing both “alarm up” and “alarm down” at the same

time.

Cal. 3 : 1

st calibration of the percentage range.

The “%” LED flashes. Select an oxygen concentration that corresponds to the highest

percentage value used, and let the system flush through until a steady readout is

achieved (at least 1 min.). Adjust the number of LEDs that should be lit using the

“alarm up” or the “alarm down” button. Save the calibration by pressing both “alarm

up” and “alarm down” at the same time.

Cal. 4 : 2nd calibration of the percentage range.

The “%” LED is constantly lit. Select an oxygen concentration that corresponds to the

lowest percentage value used, and let the system flush through until a steady readout is

achieved (at least 1 min.). Adjust the number of LEDs that should be lit using the

“alarm up” or the “alarm down” button. Save the calibration by pressing both “alarm

up” and “alarm down” at the same time.

Cal. 5 : 1

st calibration of the ppm range.

The “ppm” LED flashes. Select an oxygen concentration that corresponds to the

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 13

highest ppm value used, and let the system flush through until a steady readout is

achieved (at least 2 min.). Adjust the number of LEDs that should be lit using the

“alarm up” or the “alarm down” button. Save the calibration by pressing both “alarm

up” and “alarm down” at the same time.

Cal. 6 : 2nd calibration of the ppm range.

The “ppm” LED is lit. Select an oxygen concentration that corresponds to the lowest

ppm value used, and let the system flush through until a steady readout is achieved (at

least 3 min.). Adjust the number of LEDs that should be lit using the “alarm up” or the

“alarm down” button. Save the calibration by pressing both “alarm up” and “alarm

down” at the same time.

When saving a calibration you leave the calibration menu.

To leave the calibration menu without saving a calibration, turn off the OXI-3

6.3. Calibration procedure for OXI-3.1

Calibration of voltage output

Connect the voltmeter to the DIN connector, pin 1 (+) and pin 2 (-).

1. Supply atmospheric air.

2. Press and hold and for 5 seconds.

3. The “Ready” LED goes out.

4. Press or to set the voltage on the voltmeter to 1mV.

5. Press and at the same time. The calibration is saved, and the “Ready” LED is

constantly lit again.

Calibration of sensor

Warm up the OXI-3.1 for at least 4 hours.

The OXI-3.1 must be calibrated using 3 gases, typically:

1000ppm O2, 100ppm O2and 25ppm O2for calibration in the ppm

range. Calibration in the % range normally requires 20.9% O2

(atmospheric air), 1% O2and 0.1% O2(=1000ppm O2)

Connect the voltmeter to the DIN connector, pin 1 (+) and pin 2

(-).

1. To calibrate in the “%” range, supply 24V DC to the DIN

connector, pin 4 (+) and pin 7 (-).

2. Supply calibration gas at a flow rate of 200ml/min to the gas

inlet. Flush with the gas for at least 10 minutes until the

voltmeter readout is steady.

3. Press and hold and until “Ready” flashes (1000ppm

duty cycle 25%, 100ppm duty cycle 50%, and 25ppm duty

cycle 75%)

4. Press / hold or to set the correct reading on the voltage

output in accordance with the calibration gas (5mV/ppm).

5. Press and at the same time. The calibration is saved, and

the “Ready” LED stops flashing.

6. Repeat the procedure for each of the other gases.

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

14 PBI-210247-H UK 07/11/2005

Calibration

buttons

Note: The calibration gas is selected automatically on the basis of the current EMF when

the calibration is saved.

75%EMF > 180mV3

50%130mV < EMF < 180mV2

25%EMF < 130mV1

Ready LED flashSensor signalCalibration gas

All calibrations can be deleted by pressing and holding and for 10 seconds.

6.4. Cleaning

Use only water or a light soap solution when cleaning the front panel.

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 15

7. Error messages/ Troubleshooting

Restart the system. If the

error persists, forward the

oxygen indicator for service

1) Defective heating elementLED no. 8 in the row is

flashing

Restart the system. If the

error persists, forward the

oxygen indicator for service

1) Internal electronics errorLED no. 7 in the row is

flashing

Perform calibration.

Measuring possible, however,

by pressing any button. If

LED no. 3 flashes, the

measurement will probably

not be correct!

1) Incorrect device calibrationWhen starting up, one of the

three first LEDs in the row

flashes

Replace measuring gas hose

with high-quality hose

Check, and replace or repair

if required

Replace the reducing valve

1) The measuring gas hose

used is not oxygen

diffusion-proof

2) Leak in the system (Check

measurement with adapter

fitted directly on bottle)

3) Defective reducing valve

The oxygen indicator displays

a higher oxygen content than

expected

Replace the pre-filter

Replace the pump

1) Clogged pre-filter

2) Defective pump

The oxygen indicator reacts,

but it is slow

Check, and make connection

Replace the fuse

2AT at 230VAC

4AT at 115VAC

There is an extra fuse in the

fuse retainer

1) The oxygen indicator is not

connected to the correct

voltage

2) The fuse in the oxygen

indicator has blown

The "Power" LED is not lit

Possible solutionPossible causeProblem

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

16 PBI-210247-H UK 07/11/2005

8. Spare parts and accessories

8.1. Accessories for SGI-3 and OXI-3

vAcoustic alarm PBI 210197

vGroove probe, 1.6mm 200mm PBI 910824

vCable for converting of OXI-3 DIN signals w/instruction PBI 220145

8.2. Spare parts for SGI-3 and OXI-3

vAdapter for measuring gas bottle content PBI 210339

vAdapter for gas bottle connection PBI 910621

vDIN 8-pole connector, for signal output/input, straight PBI 910525

vDIN 8-pole connector, for signal output/input, angular PBI 960430

vFilter, internal PBI 910358

vHeater, 36V in block, complete PBI 930523

vOxygen diffusion-proof measuring gas hose, ø 5/3 mm:

length 5 m PBI 910595

length 10 m PBI 910596

length 15 m PBI 910597

vCable, mains to device, IEC, DK PBI 910499

vCable, mains to device, IEC, D PBI 910505

vCable, mains to device, IEC, UK PBI 930066

vCable, mains to device, IEC, USA PBI 930315

vCable, mains to device, IEC, I PBI 960247

vQuick coupling for reducing valve PBI 920127

vPump, 60Hz, complete PBI 210334

vPump, 50Hz, complete PBI 210335

vPCB display, complete PBI 210337

vPCB controller, complete SGI-3 PBI 210338

vPCB controller, complete OXI-3 PBI 250707

vO2sensor, complete PBI 210336

vFuse, 2AT 5x20mm (4 pcs.) PBI 210653

vFuse, 4AT 5x20mm (4 pcs.) PBI 210654

v115VAC transformer, complete PBI 210341

v230VAC transformer, complete PBI 210342

vTransportation and storage box PBI 910751

vUser’s manual, SGI-3/OXI-3/OXI-3.1 DK PBI 210246

vUser's manual, SGI-3/OXI-3/OXI-3.1 UK PBI 210247

vUser's manual, SGI-3/OXI-3/OXI-3.1 D PBI 210249

vUser's manual, SGI-3/OXI-3/OXI-3.1 F PBI 210250

vPump, heart PBI 230303

vSpring, leaf (60Hz pump) PBI 230304

vSpring, leaf (50Hz pump) PBI 230306

vFuse, TR5 0,5A (4 pcs.) PBI 230322

vFuse, TR5 3,15A (4 pcs.) PBI 230323

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 17

vKit, upgr. OXI-3 V.1.4 PBI 210692

vKit, upgr. SGI-3 V.1.3 PBI 210693

8.3. Consumables for SGI-3 and OXI-3

vFilter, external, complete PBI 920002

8.4. Spare parts for OXI-3.1

vDIN 8-pole connector, for signal output/input, straight PBI 910525

vDIN 8-pole connector, for signal output/input, angular PBI 960430

vFitting, union, Swagelok 1/4" PBI 210171

vFitting, ferrule, Swagelok 1/4" PBI 210172

vHeater, 36V in block, complete PBI 930523

vCable, mains to device, IEC, DK PBI 910499

vCable, mains to device, IEC, D PBI 910505

vCable, mains to device, IEC, UK PBI 930066

vCable, mains to device, IEC, USA PBI 930315

vCable, mains to device, IEC, I PBI 960247

vPCB controller, complete OXI-3.1 PBI 250708

vO2sensor, complete PBI 210170

vFuse, 2AT 5x20mm (4 pcs.) PBI 210653

vFuse, 4AT 5x20mm (4 pcs.) PBI 210654

v115VAC transformer, complete PBI 210341

v230VAC transformer, complete PBI 210342

vTransportation and storage box PBI 910751

vUser's manual, technical OXI-3.1 UK PBI 210129

vFuse, TR5 0,5A (4 pcs.) PBI 230322

vFuse, TR5 3,15A (4 pcs.) PBI 230323

PBI-Dansensor A/S SGI-3/OXI-3/OXI-3.1 User manual

18 PBI-210247-H UK 07/11/2005

9. Technical specifications

9.1. Sensor

Solid-state sensor with electrolyte made of stabilized zirconium oxide, which is pre-heated

to a constant temperature of 1000K (727oC). The warm-up time is approx. 20 minutes,

and an LED on the front plate indicates that the sensor is ready to measure, while a +15

VDC output signal is transmitted through the 8-pole DIN connector.

9.2. Measuring range

The device can be used to measure oxygen in inert gases, argon, nitrogen and formier gas.

Front control switch and/or electrically controlled switch for measuring gas range

selection ("RANGE"):

Green

“Formier 2%”

8.6 - 14 mA /

2.15 - 3.5 V

500 - 10 ppmFormier gas 2%

Green

“Formier 5%”

8.6 - 14 mA /

2.15 - 3.5 V

500 - 10 ppmFormier gas 5%

Green

“Formier 10%”

8.6 - 14 mA /

2.15 - 3.5 V

500 - 10 ppmFormier gas

10%

Green

“Inert”

4 - 20 mA /

1 - 5 V

5000 - 1 ppmInert

Indication LEDOutput signal

I out / V out

Measuring range

SGI-3

Green

“ppm”

4 - 20 mA /

1 - 5 V

1000 - 1 ppmppm

Green

“%”

4 - 20 mA /

1 - 5 V

20,9 - 0,1 %%

Indication LEDOutput signal

I out / V out

Measuring range

OXI-3

+/- 1%0 - 20 mA /

0 - 5 V

0 - 1000 ppmppm

+/- 1%0 - 20 mA /

0 - 5 V

0 - 100 %%

AccuracyOutput signal

I out / V out

Measuring range

OXI-3.1

SGI-3/OXI-3/OXI-3.1 User manual PBI-Dansensor A/S

PBI-210247-H UK 07/11/2005 19

This manual suits for next models

2

Table of contents

Other PBI Dansensor Measuring Instrument manuals