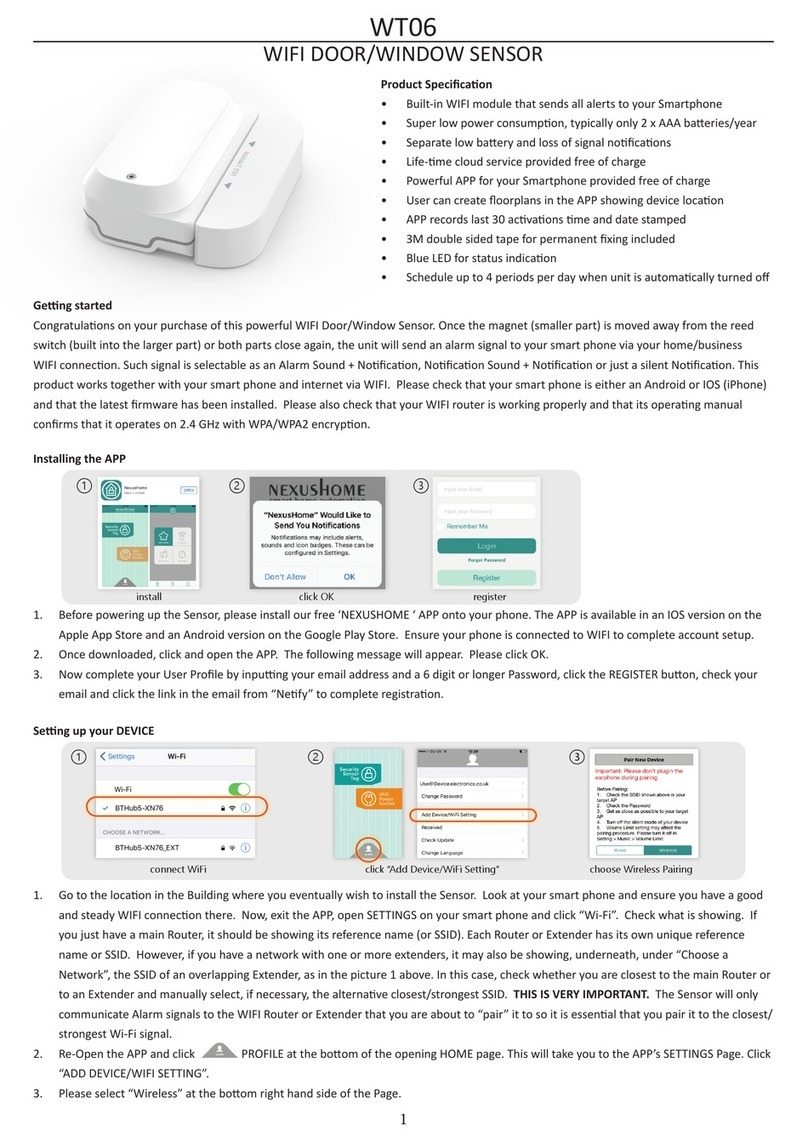

ICPQUARTZ STRAIN SENSOR OPERATION MANUAL

1

1.0 INTRODUCTION

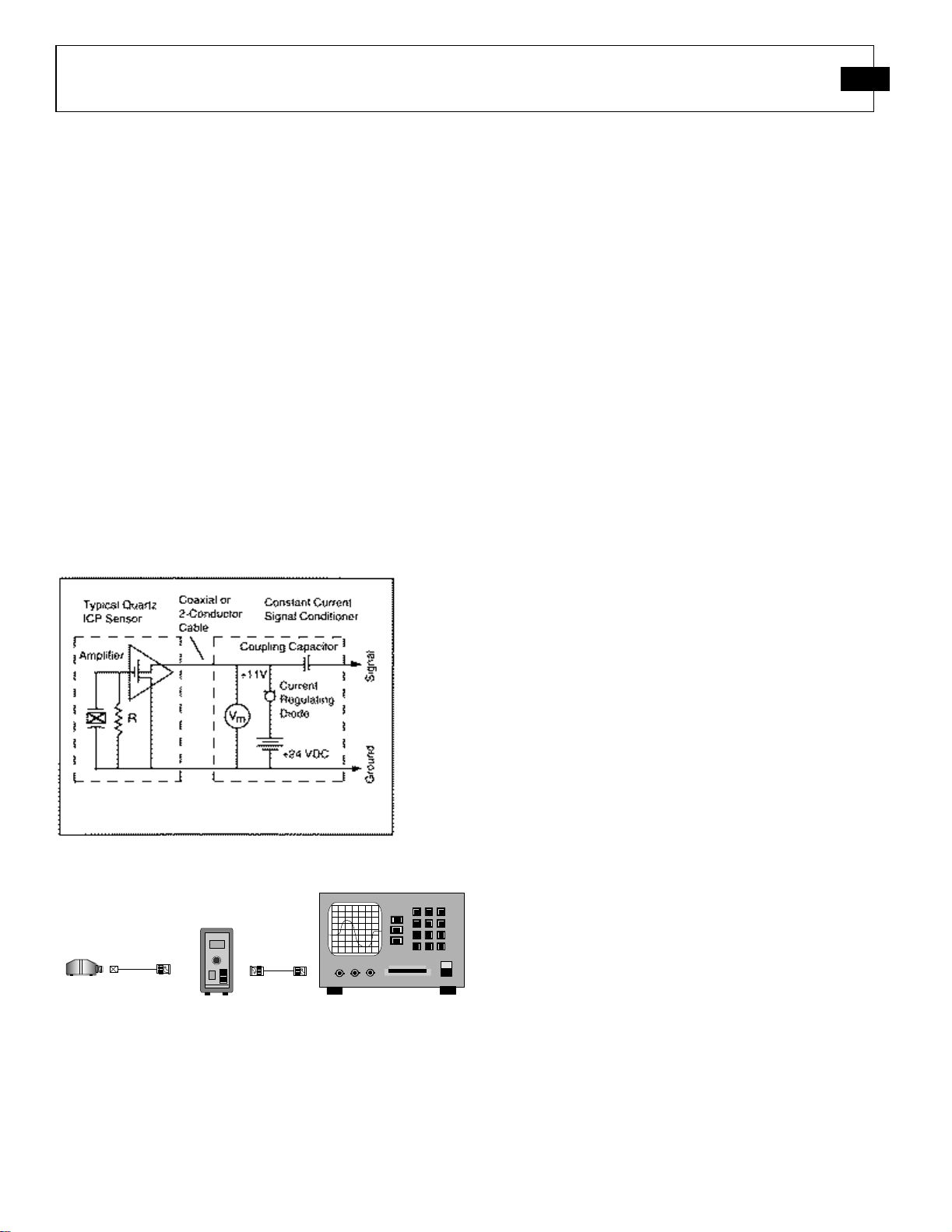

ICP quartz strain sensors incorporate a built-in MOSFET

microelectronic amplifier. This serves to convert the high

impedance charge output into a low impedance voltage signal

for analysis or recording. ICP quartz strain sensors, powered

from a separate constant current source, operate over long

ordinary coaxial or ribbon cable without signal degradation.

The low impedance voltage signal is not affected by

triboelectric cable noise or environmental contaminants.

Power to operate ICP sensors is generally in the form of a low

cost, 24-27 VDC, 2-20 mA constant current supply. Figure

1.1 schematically illustrates a typical ICP strain sensor system.

PCB offers a number of AC or battery-powered, single or

multi-channel power/signal conditioners, with or without gain

capabilities for use with strain sensors. In addition, many data

acquisition systems now incorporate constant current power

for directly powering ICP sensors. Because static calibration

or quasi-static short-term response lasting up to a few seconds

is often required, PCB manufactures signal conditioners that

provide DC coupling. Figure 1.2 summarizes a complete 2-

wire ICP system configuration.

Figure 1.1 ICP®Sensor System Schematic

Readout Device

(not supplied)

Output

Cable

ICP®Sensor

Signal

Conditioner

Standard

Sensor Cable

ICP®Strain

Sensor

Figure 1.2 Typical ICP®Sensor System

In addition to ease of operation, ICP quartz strain sensors offer

significant advantages over charge mode types. Because of the

low impedance output and solid-state, hermetic construction,

ICP quartz strain sensors are well suited for continuous,

unattended strain monitoring in harsh factory environments.

Also, ICP sensor cost-per-channel is substantially lower, since

they operate through standard, low-cost coaxial cable, and do

not require expensive charge amplifiers.

Refer to the installation/outline drawing and specification

sheet at the front of this manual for details and dimensions of

the particular sensor model number(s) purchased. The

following pages give a brief description of the sensor series,

recommended mounting procedures, operation and

recommended calibration.

In addition to standard products, PCB has the ability to design

and manufacture custom sensors/systems for specific

applications.

If questions arise regarding the operation or characteristics of

the strain sensor products as outlined in this manual, feel free

to contact an experienced applications engineer from the

Force/Torque Division of PCB toll-free 888-684-0004.

2.0 DESCRIPTION

240 series quartz strain sensors are used to monitor the

dynamic response of crimping, stamping, punching, forming

and any other applications where it is crucial to maintain

process control. These sensors are ideal in applications where

mounting directly in the load path with a force sensor is not

possible. Instead, the sensor can be mounted in an area that

will provide the highest mechanical stress for the process to be

monitored. Strain sensors are mounted to a structure by means

of a supplied socket flat head screw, which threads into a

corresponding tapped hole, and is then fastened securely as

noted in the installation section of this manual. When used

with a constant current signal conditioner, the sensor output

voltage can be resolved in units of strain and then related to

specific events that must be monitored in the process. After

defining a signature voltage response for properly

manufactured parts, the user can then determine an acceptable

upper and lower control limit in order to maintain process

control thereby preventing the acceptance of non-conforming

products as finished goods.

Versions offering full-scale measurements of 10 to 300

are available. When powered by a constant current power

supply and subjected to an input strain, an ICP strain sensor

will provide a corresponding output voltage. A positive output

voltage indicates that the structure being monitored is being

subjected to a tensile force in the sensor mounting area and

can also be resolved in units of strain. Likewise, a compressive

force in this area will result in a negative output voltage. Refer

to Sections 3.1, for recommended strain sensor mounting and

torque requirements.