4

Contents

VEGAPULS 65 • 4 … 20 mA/HART - two-wire

36515-EN-121011

Contents

1 About this document

1.1 Function ............................................................................. 6

1.2 Target group ....................................................................... 6

1.3 Symbolism used ................................................................. 6

2 For your safety

2.1 Authorised personnel ......................................................... 7

2.2 Appropriate use .................................................................. 7

2.3 Warning about incorrect use ............................................... 7

2.4 General safety instructions ................................................. 7

2.5 CE conformity ..................................................................... 8

2.6 NAMUR recommendations ................................................ 8

2.7 Radio license for Europe .................................................... 8

2.8 Radio license for USA/Canada ........................................... 8

2.9 Environmental instructions ................................................. 9

3 Product description

3.1 Conguration .................................................................... 10

3.2 Principle of operation ........................................................ 11

3.3 Packaging, transport and storage ..................................... 11

3.4 Accessories and replacement parts ................................. 12

4 Mounting

4.1 General instructions ......................................................... 14

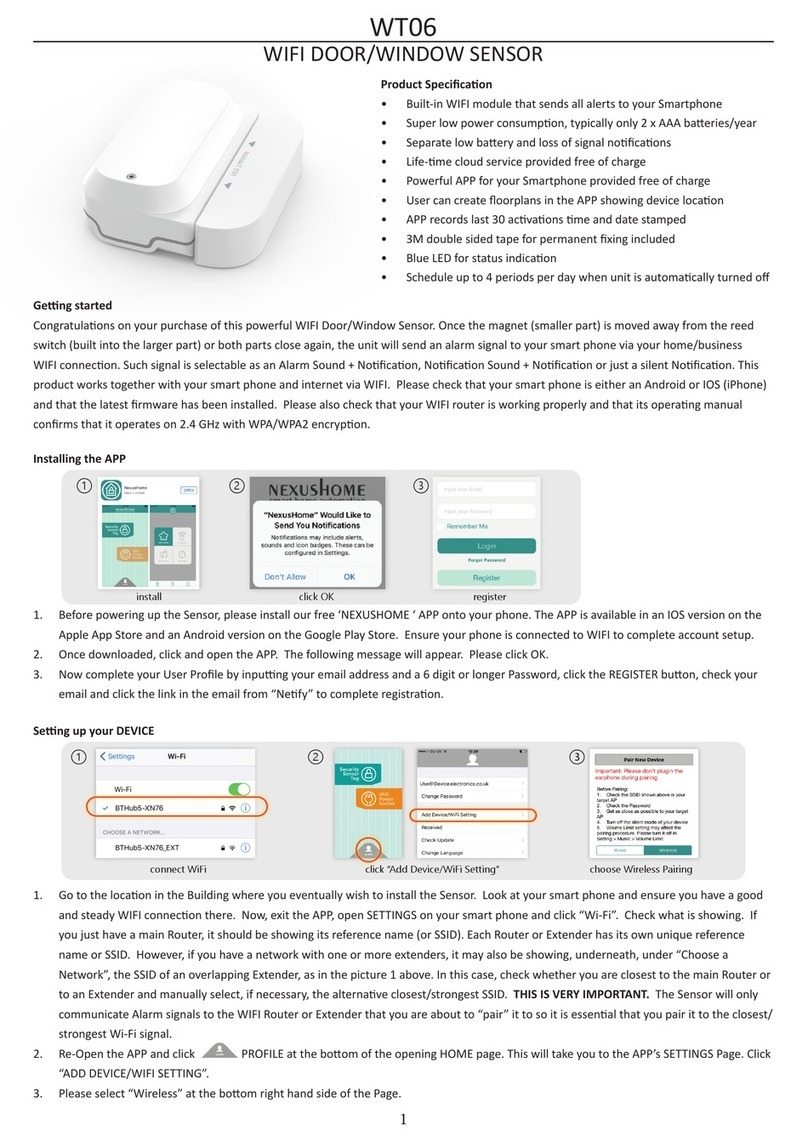

4.2 Instructions for installation ................................................ 14

5 Connecting to power supply

5.1 Preparing the connection ................................................. 19

5.2 Connecting ....................................................................... 20

5.3 Wiring plan, single chamber housing ................................ 21

5.4 Wiring plan, double chamber housing .............................. 22

5.5 Wiring plan, double chamber housing Ex d ...................... 23

5.6 Wiring plan - version IP 66/IP 68, 1 bar ............................. 24

5.7 Switch-on phase ............................................................... 24

6 Set up with the indicating and adjustment module

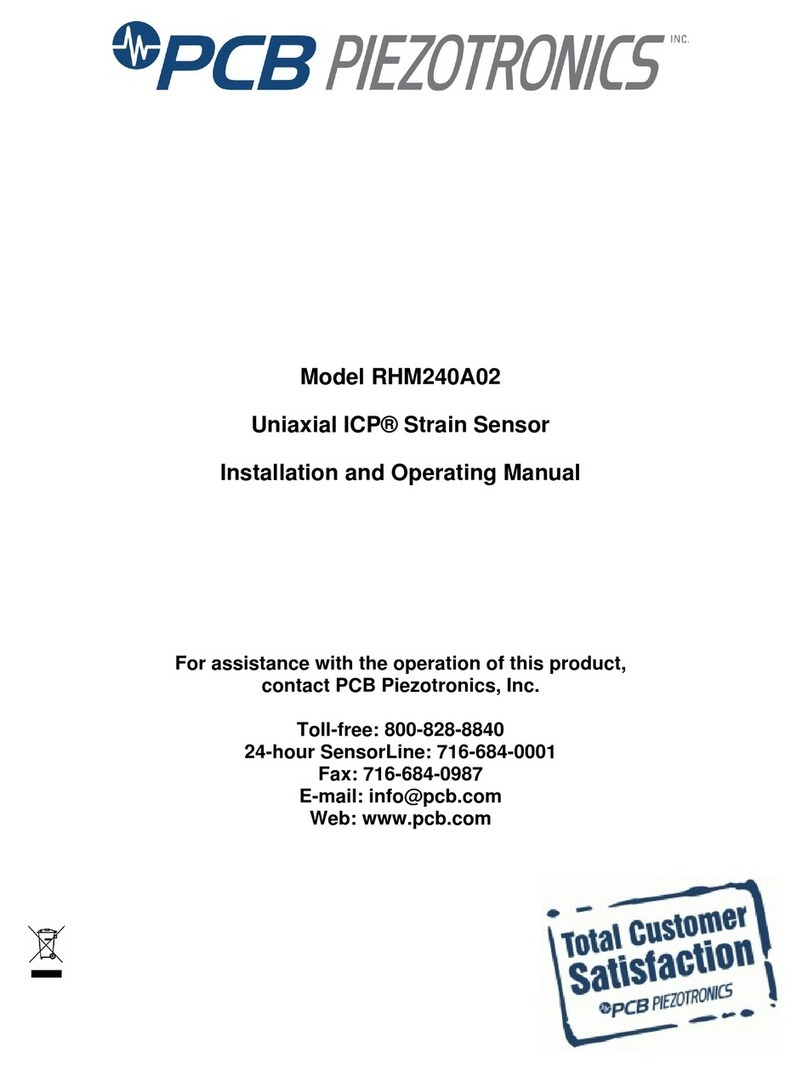

6.1 Insert indicating and adjustment module .......................... 26

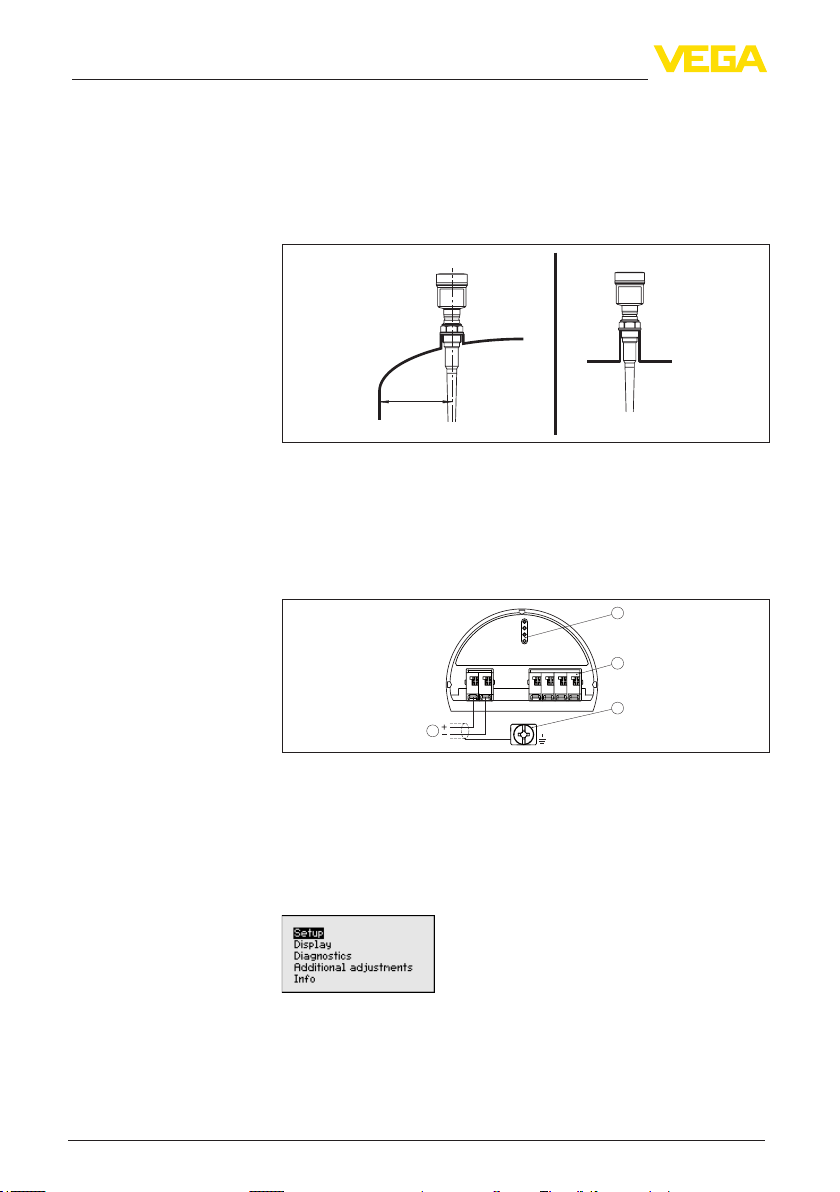

6.2 Adjustment system ........................................................... 27

6.3 Parameter adjustment ...................................................... 28

6.4 Saving the parameter adjustment data ............................. 41

7 Setup with PACTware

7.1 Connect the PC ................................................................ 42

7.2 Parameter adjustment with PACTware .............................. 43

7.3 Saving the parameter adjustment data ............................. 44

8 Set up with other systems

8.1 DD adjustment programs ................................................. 45

8.2 Communicator 375, 475 ................................................... 45

9 Diagnosis, Asset Management and service

9.1 Maintenance .................................................................... 46

9.2 Measured value and event memory ................................. 46